Does blue quartzite need sealing?

Yes, seal blue quartzite wall cladding after installation and reseal every 1-3 years depending on exposure. Use penetrating sealers designed for natural stone. Sealers protect against water absorption and staining while maintaining the stone’s natural appearance. Perform a simple water test annually: if water darkens the stone within 15 minutes, resealing is needed.

Can this product be used for exterior applications?

Absolutely. Blue quartzite passes freeze-thaw testing and performs in all climates. Its low water absorption (under 0.5%) prevents moisture damage in winter conditions. The stone resists UV fading and maintains color in direct sun exposure for decades. Exterior installations require proper flashing, moisture barriers, and weep holes per local building codes.

What is the minimum order quantity?

Our standard minimum order is 100 square meters. This quantity fills approximately one-quarter of a 20-foot container and suits medium-sized commercial projects or multiple residential jobs. Larger projects benefit from volume pricing starting at 500 square meters

How do I calculate the quantity needed?

Measure the wall area in square meters and add 15-20% for cutting waste, corners, and future repairs. Dry-stack installations need approximately 15% extra. Mortared installations with wide joints require 18-20% extra material. Our sales team can help calculate exact quantities based on your project specifications.

Can I install this product myself?

Small interior projects may be suitable for experienced DIY installers with stone working skills. Exterior installations and projects over 10 square meters should be completed by licensed masons who understand proper substrate preparation, moisture management, and structural requirements. Poor installation can lead to stone failure, moisture damage, and expensive repairs.

How does this compare to manufactured stone veneer?

Natural blue quartzite costs more upfront ($15-30/sqm) than manufactured stone ($5-15/sqm) but lasts 2-3 times longer. Natural stone maintains its appearance for 50+ years without fading or surface degradation. Each natural piece is unique, creating authentic visual appeal that manufactured products cannot replicate. The density and hardness of quartzite exceed manufactured alternatives.

What maintenance does installed stone require?

Clean stone annually with pH-neutral stone cleaner and water. Avoid acidic cleaners, vinegar, or harsh chemicals that damage sealers. Reseal every 1-3 years based on water absorption test results. Remove spills promptly to prevent staining, especially oils and wine. Properly maintained blue quartzite lasts 50+ years without replacement.

Can this stone be used around fireplaces?

Yes, quartzite handles heat up to 150°C without damage, making it safe for fireplace surrounds. Its heat resistance exceeds many other natural stones. Always maintain proper clearances from fireboxes per local fire codes. Use heat-resistant adhesives rated for high-temperature applications.

What colors and variations should I expect?

Blue quartzite features blue-gray base colors with golden rust veining, subtle ivory streaks, and natural mineral striations. No two pieces match exactly—this natural variation creates the stone’s authentic character. Each crate contains a balanced color range. For projects requiring tight color control, request samples before ordering full quantities.

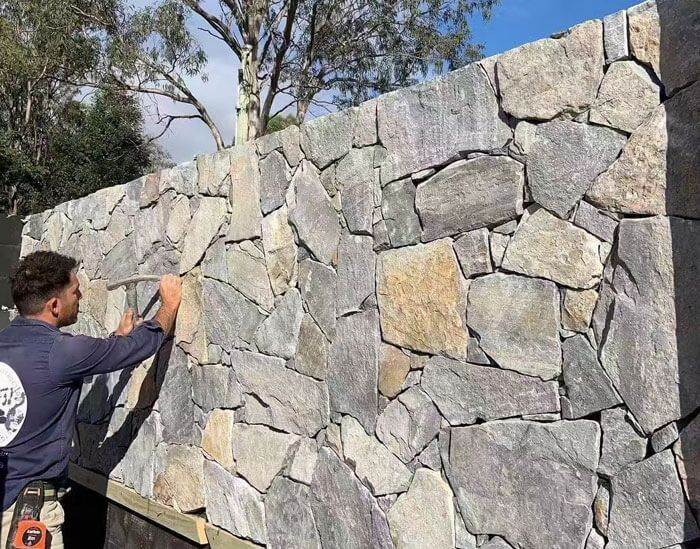

How thick are the pieces?

Edge thickness ranges from 10-40mm, with face depth (projection from wall) of 20-60mm. This variation creates natural shadow lines and dimensional texture. Thicker pieces at corners and edges provide structural strength. Random thickness variation prevents visible pattern repetition across large wall areas.

Do you provide corner pieces?

Yes, matching corner units are available to create clean 90-degree turns and professional-looking edges. Corner pieces come in two-part interlocking units that install seamlessly with field stones. Order corners separately based on the linear meters of outside corners in your project (typically 12 linear meters per crate).

What is the lead time for orders?

Standard production and shipping takes 20-30 days after deposit payment. Rush orders may be possible depending on current production schedule and stock levels. Container loading and customs clearance add 2-3 weeks for international shipments. Plan your material ordering 6-8 weeks before installation start dates to ensure timely delivery.