Natural thin stone veneer serves as the primary safeguard for developers who need to balance authentic aesthetics with strict structural weight limits and long-term liability. Mistaking high-performance quarried stone for inferior manufactured imitations often leads to rapid site degradation, color loss, and expensive warranty claims that eat into project margins. Distinguishing between these materials is a matter of protecting the building envelope and the developer’s bottom line.

This guide details the technical specifications of real rock, from the sourcing of individual pieces at the quarry to the application of adhered thin masonry systems. We examine the physics of natural mineral pigments and why they withstand environmental stress better than synthetic dyes. Following these industry standards for vertical integration and material selection ensures a durable finish that maintains its structural integrity and value for decades.

The Technical Definition of Natural Thin Stone Veneer

Natural thin stone veneer represents a technical transition from heavy structural masonry to high-performance surface engineering, defined by a strict 15-pound per square foot weight limit and 100% mineral integrity.

This material category consists of 100% real quarried stone, which separates it from manufactured or “cultured” alternatives that rely on concrete and synthetic pigments. We source raw materials directly from specific quarry veins to ensure mineral consistency across entire product lines. This direct sourcing maintains the organic textures and unique color variations found in natural slate, quartzite, and marble. Unlike composite materials, these stone pieces contain no artificial binders that degrade when exposed to environmental stressors like high heat or heavy moisture.

Weight Thresholds and Structural Load Requirements

Industry standards classify thin veneer by its ability to adhere to vertical surfaces without the need for structural footings or foundation ledges. The system complies with building codes for adhered masonry veneers by staying under the 15 pounds per square foot threshold. Our technical specifications maintain a weight of approximately 65kg/m² (13.3 lbs/sq ft), ensuring compatibility with modern substrates.

- The lightweight profile allows for installation on various surfaces, including cement board, brick, and concrete.

- By eliminating foundation requirements, project timelines accelerate while reducing structural engineering costs.

- The material maintains a thickness of 25–40mm to balance authentic depth with weight efficiency.

Dimensional Specifications and Precision Cutting

The technical standard for loose stone veneer focuses on a “Sawn-Back” finish. Every piece undergoes precision cutting to create a 100% flat bonding surface. This engineering choice reduces on-site labor costs by up to 30% because installers spend less time shimmying or trimming stones to fit the wall. We use diamond-bladed saws to maintain these tolerances while preserving the natural, irregular face of the stone.

While dimensions for individual pieces vary to create an authentic random-lay pattern, the depth is strictly controlled. This ensures that when the stone is combined with matching L-shaped Corners—known as “Authentic Masonry Corner Wraps”—the finished wall looks indistinguishable from a full-depth structural block. This “Bespoke Random-Lay” approach avoids the repetitive patterns and visible joints common in pre-assembled panels.

ASTM Compliance and Physical Performance Standards

Technical performance metrics for natural stone focus on durability and safety. Natural thin stone is inherently non-combustible, making it the primary choice for fireplace surrounds and high-heat areas. Because the material is 100% mineral, it meets the highest safety requirements for fire resistance without releasing toxic off-gassing during exposure.

- High-density quartzite and granite variants provide superior resistance to moisture and staining.

- Natural mineral pigments provide permanent UV resistance, preventing the fading seen in painted concrete substitutes.

- The stone remains stable through extreme freeze-thaw cycles, maintaining structural integrity for over 50 years.

How Real Rock Differs from Manufactured Stone Substitutes

Genuine thin stone veneer provides the structural longevity and mineral stability that concrete-based replications fail to achieve over multi-decade lifecycles.

Geological Authenticity vs. Concrete Replications

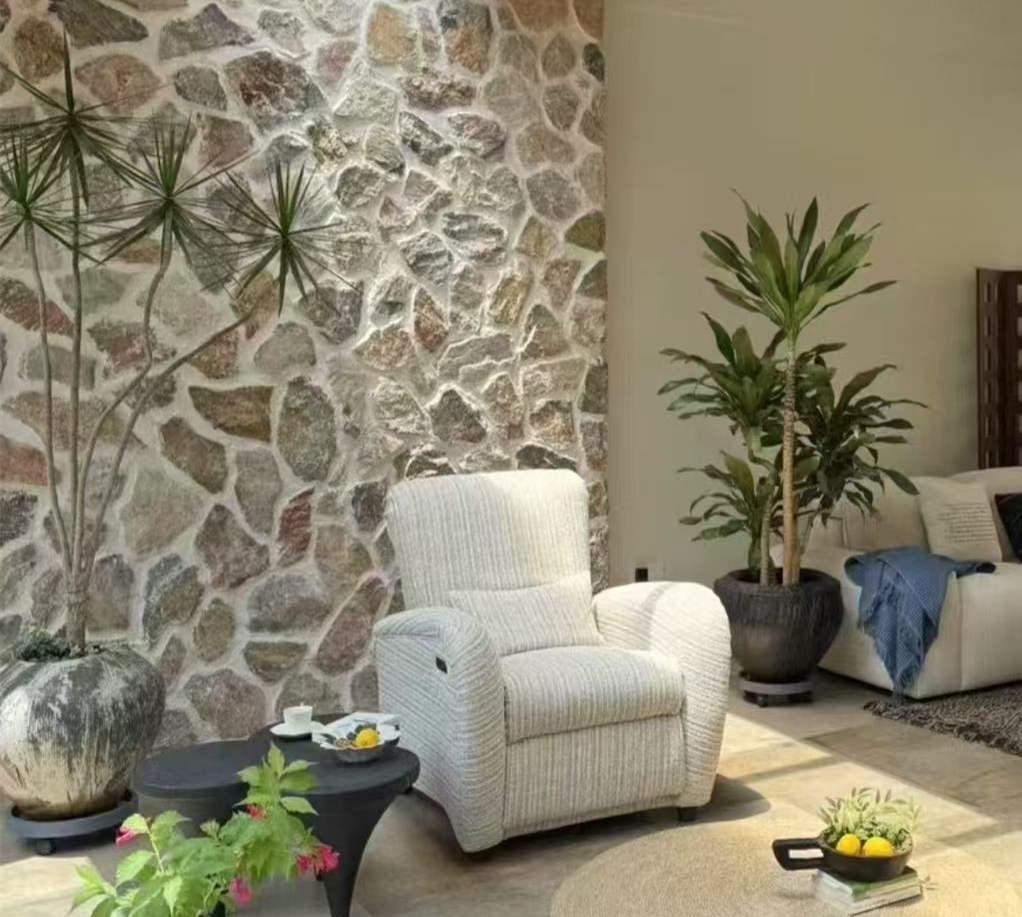

Natural stone consists of 100% quarried rock, offering unique textures that artificial molds cannot replicate. Every piece features one-of-a-kind mineral patterns and split-face textures derived from slate, quartzite, or marble. The 2026 design market prioritizes the tactile depth of genuine stone over the smoother, more uniform finish of cast products.

Manufactured stone relies on concrete composites and repetitive molds. This process often results in visible pattern cycles on large surfaces, a phenomenon known as “repetitive wall syndrome.” Using loose, individually sawn-back piedra natural ensures zero-repeat natural variation, as no two pieces of quarried mineral are identical.

Natural Pigment Stability and UV Resistance

Genuine stone maintains its original hue indefinitely because its color results from deep-seated mineral composition rather than surface dyes. These natural pigments never fade or peel, even when exposed to intense climate extremes and high UV radiation. This permanent color profile ensures that additions made years later still match the existing installation.

| Performance Feature | Natural Thin Stone Veneer | Manufactured Stone (MSV) |

|---|---|---|

| Composition | 100% Quarried Mineral | Concrete & Chemical Pigments |

| UV Stability | Indefinite (Fade-Proof) | Susceptible to Oxidation/Fading |

| Average Lifespan | 50 – 100+ Years | 20 – 30 Years |

| Moisture Absorption | Very Low (High Density) | High (Porous Concrete) |

Manufactured substitutes use surface-level pigments that oxidize and lose vibrancy over time. These synthetic materials often require periodic staining or specialized sealants to slow the degradation process. In contrast, the high-density quartzite and granite used in authentic veneers offer climate-tested durability without the need for chemical intervention.

Structural Performance and Maintenance Needs

Real stone provides superior resistance to weathering and chemical exposure compared to porous concrete-based alternatives. Natural stone withstands freeze-thaw cycles without the crumbling or “efflorescence”—the white salt deposits common in manufactured masonry—that plagues concrete products. Its high-density composition resists moisture absorption, keeping the stone structurally sound for exterior facades and water features.

Maintenance requirements remain minimal for authentic stone. Simple cleaning with water or pH-neutral solutions suffices, avoiding the specialized care synthetic stone surfaces demand. Because the color runs through the entire stone, minor chips or scratches remain invisible, whereas damage to manufactured stone reveals the dull concrete core underneath.

Investment Value and Environmental Footprint

Using authentic materials increases property appraisal value and meets modern sustainability standards for indoor air quality. Homebuyers and commercial investors view real stone as a high-value asset, whereas manufactured stone often serves as a temporary aesthetic fix. Reports indicate that stone projects deliver some of the highest returns on investment in the building sector.

- Natural stone produces zero off-gassing and contains no VOCs, supporting healthy indoor air quality.

- The longevity of quarried stone reduces the need for frequent renovation and construction waste.

- Lower lifecycle costs make natural veneer a more sustainable choice for large-scale B2B developments.

Premium Natural Stone for High-Margin Projects

The Structural Benefits of Adhered Thin Masonry Systems

Adhered thin masonry systems eliminate the need for heavy structural footings and foundation ledges by reducing the dead load to under 15 pounds per square foot, enabling stone application on high-occupancy commercial facades and multi-story residential projects.

Elimination of Foundation Ledges and Structural Footings

Natural thin stone veneer systems from Top Source Stone weigh between 8 and 13 pounds per square foot. This lightweight profile removes the requirement for heavy concrete ledges or specialized structural footings that traditional 3-to-5-inch thick stone demands. Architects can now design stone facades for multi-story buildings without adding costly structural supports, simplifying the engineering process for 2026 commercial developments.

By reducing the total weight by up to 75% compared to full-depth masonry, these systems allow for stone application on existing structures where traditional masonry would exceed weight limits. This flexibility is critical for renovation projects that aim to achieve a premium aesthetic without a complete foundation overhaul.

| Structural Metric | Traditional Full Stone | Thin Stone Veneer (Adhered) |

|---|---|---|

| Average Weight | 40 – 60 lbs / sq. ft. | ~13 lbs / sq. ft. (65kg/m²) |

| Deflection Limit | L/600 (Rigid) | L/360 (Flexible) |

| Support Requirement | Foundation Ledge/Lintels | Substrate Adhesion |

Reduced Framing Loads and Deflection Standards

Adhered systems allow for more flexible framing tolerances, which lowers the overall cost of the building’s skeleton. Thin masonry requires a deflection limit of L/360, which is significantly less rigid than the L/600 standard required for heavy masonry. This difference means contractors can install these materials over standard wood or steel studs without additional reinforcement.

- Lower structural demands translate to direct savings in framing materials and labor.

- Design flexibility increases for cantilevered sections and high-wall applications.

- Precision-sawn backs ensure a flat bonding surface, reducing on-site labor costs by up to 30%.

Enhanced Adhesion with High-Strength Epoxy Technology

Modern manufacturing utilizes proprietary resins to ensure individual stones remain permanently bonded to the substrate. High-strength epoxy resin resists temperature fluctuations and environmental stress better than traditional mortar bonds, which are prone to cracking in freeze-thaw cycles.

We maintain strict thickness control at 25–40mm to optimize the surface area for adhesion. Controlled factory environments ensure consistent application of adhesives under optimal pressure and temperature, verified by three-stage quality inspections before any pallet leaves the facility.

Integration with Modern Moisture and Thermal Barriers

The thin profile of adhered systems facilitates the inclusion of advanced drainage planes and continuous insulation layers. Panels and loose stone units install easily over cement board and drainage mats to protect the building envelope from moisture infiltration, a critical factor for long-term durability.

Non-combustible natural stone meets strict 2026 fire safety standards for high-occupancy commercial facades. By accommodating continuous insulation, these systems help projects meet updated energy efficiency codes without the need for bulky, complex wall assemblies.

Understanding the “Individual Piece” (Loose) Sourcing Model

The loose sourcing model prioritizes site-specific artistry and long-term structural integrity over the standardized convenience of pre-assembled modular panels.

Architects utilize individual pieces to craft bespoke textures and color gradients that respond to site-specific lighting conditions. This loose stone approach prevents the repetitive “stamped” look typical of pre-glued panels, allowing for a “Bespoke Random-Lay Pattern” that highlights the stone’s natural character. Because every piece is 100% piedra natural, the variation in veining and mineral composition ensures no two installations are identical, which is a critical requirement for high-end residential and commercial projects. Designers leverage varying stone sizes to break up visual monotony on large vertical surfaces, creating an organic flow that manufactured products cannot replicate.

- Designers use individual pieces to match specific site textures and light behavior.

- Natural variation ensures distinct character for premium architectural facades.

- Variable sizing prevents the visual “pattern repeat” seen in modular stone systems.

Labor Requirements and Masonry Timelines

Successful installation of loose thin stone veneer requires a higher tier of masonry expertise and a longer project window. Masons must hand-select and fit each piece, which naturally increases labor hours per square foot compared to modular alternatives. Professional installers focus on precise joint management and stone orientation to ensure both structural integrity and a balanced aesthetic. Current 2026 project schedules reflect these extended installation windows, prioritizing precise hand-tooling to achieve a professional “Authentic Masonry Corner Wrap” using L-shaped corner pieces that mimic full-depth structural blocks.

- Skilled masonry is required to hand-select and fit individual stones for a natural look.

- Professional joint management ensures structural balance and aesthetic consistency.

- Project timelines account for manual tooling to achieve authentic masonry standards.

Long-Term Durability and Performance Standards

Loose natural stone offers a durability cycle exceeding 50 years, significantly outlasting the 25–30 year life expectancy of artificial substitutes. Because the material consists of 100% natural mineral pigments, it resists fading from UV exposure and harsh weather conditions. High-density quarried stone, such as the quartzite and granite varieties used in thin veneers, maintains its physical appearance even in high-traffic commercial zones or corrosive coastal environments. The “Individually Sawn-Back” finish provides a flat bonding surface that ensures maximum adhesion, preventing the delamination issues common in lower-quality manufactured stone.

- The 50-year durability cycle doubles the lifespan of most manufactured alternatives.

- Natural mineral pigments prevent UV-induced color loss over decades of exposure.

- High-density stone maintains structural integrity in coastal or high-traffic areas.

Direct Sourcing Impacts on Project Budgets

To manage project costs for premium loose stone, procurement teams often bypass middle-tier distributors in favor of direct factory-to-site shipping models. Direct sourcing reduces markup costs and makes authentic stone competitive with high-end manufactured products. Strategic logistics, including reinforced plywood crates and optimized loading for 17.5 to 26-ton containers, minimizes breakage during transit. For large-scale developments, B2B procurement allows for material consistency by extracting the entire order from a single quarry vein, ensuring color harmony across the entire installation.

- Direct factory-to-site shipping models significantly reduce middleman markups.

- Reinforced packaging and optimized logistics mitigate the risk of transit damage.

- Single-batch quarry extraction ensures color consistency across large-scale projects.

Why Natural Mineral Pigments Never Fade Over Decades

Natural mineral pigments provide permanent color fastness because they exist as chemically inert components within the stone’s geological matrix, whereas manufactured substitutes rely on surface-level synthetic dyes.

Inorganic Composition and UV Stability

Natural stone derives its color profile from inorganic mineral pigments, such as iron oxides and silicates, which possess inherent chemical stability against solar radiation. Unlike synthetic or organic dyes used in residential siding, these mineral pigments do not break down when exposed to intense ultraviolet rays. This geological permanence ensures that the deep ochres, charcoal greys, and earthy tans of a quarry-sourced veneer remain unchanged regardless of sun exposure levels.

The 2026 industry standard for architectural stone emphasizes that inorganic earth pigments maintain their structural and visual integrity over multiple decades. We observe that piedra natural remains vibrant because the color is a fundamental part of the mineral matrix rather than a surface-level additive. This “Full-Depth Visual Integrity” means that even if the stone faces minor surface abrasion, the color underneath remains identical to the exterior.

Natural Stone vs. Pigmented Concrete

Manufactured stone veneer, essentially a pigmented concrete composite, utilizes artificial colorants that often leach or oxidize over time. This process leads to noticeable fading, graying, and a “washed out” appearance within just a few years of installation. In contrast, real stone sourced through a direct quarry model offers permanent color that bypasses the maintenance cycles required for painted or dyed alternatives.

- High-Density Quartzite Integrity ensures superior resistance to moisture-induced pigment leaching.

- Zero-Repeat Natural Variation guarantees that tonal shifts are geological, not the result of manufacturing errors.

- Authenticity of quarried stone ensures the texture and tone remain consistent through the entire 25–40mm thickness.

Resistance to Environmental Weathering

Natural minerals are significantly less reactive to environmental pollutants and acidic rain compared to synthetic finishes. This chemical resilience prevents the “chalking” effect—a white, powdery residue—often seen on the surface of aged manufactured products. High-density stone types, such as those found in our Blue Quartzite or Granite series, provide a low-maintenance solution that survives harsh weather cycles without losing visual impact.

Climate-Tested Durability plays a vital role in long-term project value. While we recommend professional sealing with pH-neutral stone sealants to provide an extra layer of protection against organic staining, the mineral colors themselves breathe and age naturally. This creates a desirable patina over decades that adds character to the architecture rather than signaling material failure.

Why Vertical Integration (Quarry to Factory) Ensures Quality

Controlling the supply chain from the extraction point through final crate inspection eliminates mineral variability and ensures that every piece of thin stone veneer maintains the structural density required for high-performance masonry.

Direct Raw Material Control from the Source

We extract raw materials directly from our proprietary quarries to maintain absolute mineral consistency and structural integrity. Owning the source allows us to grade the stone before it ever reaches the processing facility. This early-stage filtering identifies and removes sub-par materials that lack the density or aesthetic uniformity required for thin veneer applications.

This direct oversight effectively prevents the common industry problem of color or texture shifts caused by mixing stones from different external vendors. By sourcing from the same quarry vein for each order, we ensure that large-scale architectural projects maintain visual harmony across the entire building envelope, avoiding the patchy appearance often found in outsourced products.

| Quality Metric | Integrated Source Factory | Outsourced Trading Entity |

|---|---|---|

| Mineral Consistency | Single-vein sourcing from owned quarries. | Mixed batches from multiple third-party pits. |

| Backing Precision | 100% Sawn-back with infrared calibration. | Varying flatness; often manual split-back. |

| Inspection Depth | Three-stage (Quarry, Factory, Pre-ship). | Final spot-check only (if applicable). |

Precision Manufacturing and Advanced Processing

The transition from raw block to thin veneer occurs under one roof, utilizing infrared cutting equipment to achieve precise dimensions. This technology ensures that every stone possesses a 100% sawn-back finish, providing a flat bonding surface that reduces on-site labor costs by up to 30%. Unlike manual splitting, our mechanical process maintains a strict thickness control of 25–40mm, which is vital for adhering to weight limits on modern wall substrates.

- We implement a three-stage quality check: once after primary cutting, again during secondary sizing, and a final inspection before packaging.

- Our high-strength epoxy bonding processes are monitored for temperature and pressure, ensuring that the stone retains its integrity in extreme freeze-thaw cycles.

- Precision calibration eliminates dimensional drift, allowing for a bespoke random-lay pattern that remains tight and structurally sound.

Streamlined Logistics and Packaging Integrity

Vertical integration extends to how we protect and move the product. We manage the entire supply chain, shipping over 220 containers annually through a specialized logistics team. By handling our own loading, we eliminate the risks associated with third-party warehouse handling, where stone breakage frequently occurs due to improper stacking or weight distribution.

Our packaging utilizes reinforced cartons and fumigated wooden crates designed to withstand the rigors of international transit. Strategic loading techniques maximize container space while adhering to strict port weight standards—17.5 tons for standard US ports or up to 26.5 tons for heavy-weight approved destinations. This comprehensive oversight ensures that the stone arriving at the project site matches the quality of the stone that left the quarry.

Conclusion

Selecting natural thin stone veneer provides a permanent architectural solution that avoids the fading and degradation typical of manufactured substitutes. These individually sawn-back stones combine the installation efficiency of lightweight masonry with the authentic visual depth of traditional dry-stack walls. Direct quarry sourcing ensures the technical consistency and mineral integrity required for professional B2B procurement and long-term property value.

Verify your project specifications to ensure they meet these standards for natural stone authenticity and structural performance. Contact Piedra fuente superior today to request a material sample or to access our full technical procurement catalog.

Preguntas frecuentes

Is thin stone veneer real stone?

Yes, natural thin stone veneer is 100% real stone quarried from the earth. Unlike manufactured or “faux” stone, which is made from molded concrete and pigments, thin veneer is simply authentic stone that has been cut to a thickness of 3/4″ to 1-1/4 inches. It maintains the same mineral composition, texture, and performance characteristics as full-thickness masonry.

How long does natural stone veneer last?

Natural stone veneer is designed to last a lifetime, often exceeding 50 to 100 years with minimal maintenance. Because it is a natural material, it possesses superior freeze-thaw resistance and low water absorption, allowing it to withstand harsh environmental conditions and structural aging far better than synthetic alternatives.

Does real stone veneer increase property value?

Investing in real stone veneer significantly boosts property value and curb appeal. Real estate industry standards consistently rank stone masonry as one of the highest-return home improvement projects, often recovering a substantial portion of the installation cost upon resale due to its perceived luxury, durability, and timeless aesthetic.

Is thin stone veneer fire-resistant?

Yes, natural thin stone veneer is inherently fire-resistant and non-combustible. As a natural mineral product, it typically carries a Class A fire rating, making it an ideal choice for fireplace surrounds, chimneys, and exterior cladding in wildfire-prone areas where safety and building code compliance are paramount.

What is the thinnest real stone you can cut?

Standard natural thin stone veneer is typically cut to a thickness of 3/4″ to 1-1/4 inches to ensure it meets building code weight requirements of less than 15 pounds per square foot. While specialized “ultra-thin” stone panels for interior or furniture applications can be sliced as thin as 1/16″ (often backed by fiberglass or carbon fiber), structural veneer for masonry applications maintains the 3/4″ minimum to ensure durability and a realistic profile.

Does natural stone veneer fade over time?

No, natural stone veneer does not fade. Unlike manufactured stone, which uses surface pigments that can bleach under UV exposure, the color of natural stone is consistent throughout the entire piece. While it may develop a slight natural patina over decades of weathering, its fundamental color and character remain permanent.