Selecting the right pool area stone directly impacts long-term maintenance budgets and property liability for commercial and residential developments. Choosing materials based on appearance alone often results in premature surface degradation, as salt and chlorine exposure cause concrete-based faux stones to crumble or lose their structural integrity. These failures lead to increased repair costs and safety hazards that can compromise the project’s bottom line.

This technical evaluation compares the performance of natural quartzite and travertine against manufactured stone veneers in harsh aquatic environments. We analyze slip resistance metrics, the chemical reaction of salt on porous surfaces, and the causes of delamination in high-moisture zones. Use this data as a specification guide to ensure durability and aesthetic consistency across pool surrounds and water features.

The Corrosive Effect of Chlorine and Salt on Concrete Stone

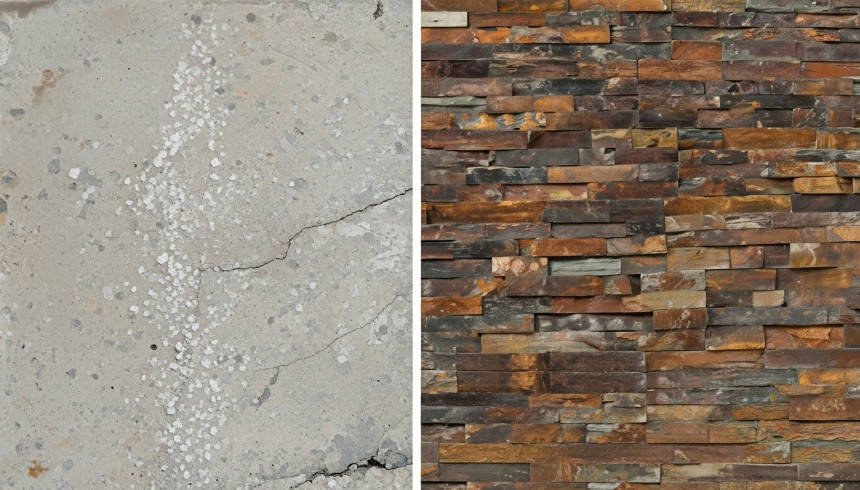

Man-made concrete stone lacks the mineral density to resist haloclasty, making it a liability in salt-water pool environments compared to the crystalline structure of natural quartzite and slate.

Chloride Penetration in Cementitious Binders

Concrete stone relies on cement-based binders that lack the inherent density of natural quarried minerals. Chloride ions from pool water easily infiltrate the porous structure of these man-made materials, leading to internal chemical destabilization. These chlorides react with the calcium hydroxide in the concrete, which increases the material’s permeability over time.

As permeability increases, moisture reaches deeper into the panel. This process accelerates the breakdown of internal adhesives and compromises the overall bond. While piedra natural maintains its integrity, the cementitious matrix in faux stone effectively acts as a sponge for corrosive pool chemicals.

Surface Spalling and Salt Crystallization

Salt water creates a unique physical threat through a process called haloclasty. When water evaporates on the surface of faux stone, it leaves behind concentrated salt deposits within microscopic voids. As these salt crystals grow, they exert significant outward pressure on the pore walls.

| Performance Metric | Concrete Stone (Faux) | Top Source Natural Stone |

|---|---|---|

| Chemical Resistance | Low; Cement binders react with chlorides | High; Inert mineral composition |

| Surface Durability | Prone to spalling and flaking | Resists crystal expansion (Haloclasty) |

| Color Stability | Pigments fade under chlorine exposure | Permanent, same-vein quarry color |

This internal pressure causes the thin face of the concrete stone to chip, flake, or spall. Top Source Stone ledger panels avoid these issues by utilizing 100% natural minerals like quartzite and slate. These materials feature a dense crystalline structure that prevents the deep penetration required for salt-driven structural damage.

Efflorescence and Pigment Leaching

Chlorine acts as a bleaching agent on the iron-oxide pigments used to color man-made stone. This chemical reaction leads to aesthetic degradation, often resulting in a patchy, “washed-out” appearance. Secondary efflorescence further compounds the problem as soluble salts migrate to the surface, forming unsightly white powdery streaks that are difficult to scrub away.

- Iron-oxide pigments in faux stone react poorly with pool sanitizers.

- Soluble salts create a recurring cleaning cycle through surface efflorescence.

- Natural stone maintains permanent color without the need for frequent tinted resealing.

Impact on Structural Integrity and Adhesion

Prolonged exposure to salt and chlorine weakens the bond between the stone composite and its backing system. Salt air and splash zones create a corrosive environment that degrades low-grade binders found in budget-tier stone panels. This degradation can lead to delamination, where the face of the stone separates from the substrate.

Our natural stone ledger panels utilize high-strength epoxy resin formulated to resist chemical breakdown. This engineering ensures the installation withstands 2026 durability requirements for high-end pool and coastal projects. Choosing natural minerals eliminates the risk of binder failure, providing a long-term solution for resort-style aquatic environments.

Why Natural Quartzite and Travertine are Ideal for Pools

Natural quartzite and travertine provide a high-density, thermally stable alternative to concrete-based veneers, ensuring pool surrounds remain cool underfoot and resistant to the chemical degradation common in saltwater environments.

Selecting materials for pool environments requires a focus on thermal performance and mineral density. Unlike manufactured “faux” stones that rely on cementitious binders and surface-level pigments, natural stone possesses an inherent geological structure that manages environmental stressors naturally. Quartzite and travertine stand out because they solve the two primary issues facing modern pool decks: extreme heat absorption and chemical erosion from chlorine or salt systems.

Thermal Regulation and Heat Management

Travertine possesses a unique cellular structure that remains cool underfoot, even when exposed to direct sunlight in high-temperature regions like the US Sunbelt or the Middle East. This thermal efficiency stems from the stone’s natural air pockets, which act as insulators against solar radiation. While man-made concrete stones absorb and retain heat—often reaching scorching temperatures that make pool decks unusable—travertine dissipates thermal energy rapidly.

| Performance Metric | Piedra Natural (Quartzite/Travertine) | Manufactured Stone (Concrete-Based) |

|---|---|---|

| Heat Retention | Low; naturally dissipates solar radiation. | High; reaches 140°F+ in direct sun. |

| UV Stability | Permanent mineral colors; no fading. | Surface pigments bleach over 2-5 years. |

| Salt Resistance | High density prevents internal crystallization. | Porous structure leads to spalling. |

Quartzite further enhances safety by reflecting high levels of solar radiation. Its crystalline composition prevents the surface from reaching the dangerous temperatures common with dark, man-made materials. For contractors and developers, this makes quartzite the preferred choice for tanning ledges and high-traffic splash zones where bare-foot comfort is a non-negotiable requirement.

Chemical Stability and Low Absorption

The high mineral density of quartzite provides a natural defense against the corrosive environments created by chlorine and saltwater systems. In salt-water pools, the primary threat is haloclasty—a process where salt water enters a material’s pores, crystallizes, and expands, eventually causing the surface to flake or pit. Because quartzite has exceptionally low porosity, it resists this internal erosion far better than standard concrete or softer limestones.

- Quartzite’s low water absorption reduces the risk of salt crystallization and internal structural damage.

- Natural stone surfaces withstand the chemical breakdown often seen in pigmented concrete stones when exposed to pool shocks and pH fluctuations.

- Dense stone prevents the “bleaching” effect caused by heavy chlorine concentrations.

UV Resistance and Color Retention

Genuine stone panels maintain their aesthetic integrity over decades because they lack artificial dyes. The colors found in Alaska Gray or Golden Honey quartzite are part of the stone’s geological makeup, forged over millions of years. Exposure to intense ultraviolet rays does not cause these minerals to wash out or bleach.

In contrast, manufactured stone utilizes iron oxide pigments that sit near the surface. Constant UV exposure and water splashes eventually strip these colors, leaving behind a dull, grayish concrete substrate. Choosing natural stone eliminates the need for frequent reapplications of expensive color enhancers or surface stains, providing a much higher long-term ROI for the property owner.

Structural Efficiency and Ease of Application

Modern ledger stone panels combine the durability of full-bed masonry with a lightweight profile suitable for contemporary pool builds. Top Source Stone ledger panels weigh between 8-12 lbs per square foot, which allows for installation on standard pool bond beams without the need for intensive structural modifications or heavy-duty masonry supports.

- Precision-cut interlocking Z-shape systems allow contractors to complete pool surrounds faster than traditional stone masonry.

- CNC diamond-blade edges ensure a seamless “male-female” connection that hides joints and prevents water infiltration behind the panel.

- Matching L-corners provide a professional wrap-around finish for water features and raised pool walls, reducing on-site labor costs.

Scale Your Business With Premium Ledger Panels

Slip Resistance: Comparing Natural Texture to Molded Surfaces

Achieving safety in high-moisture pool zones requires a shift from measuring initial friction to evaluating how surface textures withstand the corrosive effects of chlorine and salt over a ten-year cycle.

Natural stone panels, specifically our Rough Series, provide mechanical grip through irregular, multi-dimensional clefts formed during the quarry splitting process. These surfaces feature varying depths between 1 and 1.75 inches, creating physical resistance that prevents hydroplaning. Unlike smoothed materials, the inherent mineral composition of quartzite and slate provides a micro-texture that remains effective even when submerged or saturated with splash-back.

Split-face textures effectively break surface water tension. This prevents the formation of a continuous liquid film that typically leads to slip-and-fall incidents. By utilizing authentic quarried stone, we ensure the surface profile remains a structural part of the material. This differs from finished products where the texture is merely a top-layer treatment that can wear down through foot traffic or chemical cleaning.

| Performance Metric | Natural Split-Face (Piedra fuente superior) | Engineered Molded Surfaces |

|---|---|---|

| Texture Origin | Structural quarry veins (Natural Cleft) | Top-layer pigmented patterns |

| UV Stability | Inherent stability; zero fading | Variable; prone to pigment bleaching |

| Chemical Resistance | High salinity and humidity tolerance | Susceptible to chloride-induced erosion |

Performance of Engineered Molded Surfaces in Pool Zones

Engineered surfaces utilize repeat patterns and sharp points to achieve consistent slip resistance ratings across large-scale installations. These molded profiles often include specific drainage channels designed to move water away from contact points. While these systems provide uniform friction coefficients initially, they rely on concrete-based composites and pigmented top layers.

Data indicates that while molded surfaces excel in commercial environments requiring certified, identical traction levels for compliance, they face longevity challenges. The top layers may fade or wear down over time when exposed to the abrasive nature of pool maintenance chemicals. For B2B buyers, this necessitates a trade-off between initial laboratory test results and the decade-long durability found in natural minerals.

Surface Integrity and UV Exposure Standards for 2026

Building codes in 2026 prioritize materials that maintain traction despite constant exposure to sun and pool chemicals. Natural ledger stone resists UV degradation, ensuring that the slip-resistant texture does not become brittle or smooth. In contrast, many concrete-based molded products experience surface erosion when exposed to heavy chlorine or salt spray, which can eventually lead to the texture “peeling” or delaminating from the substrate.

- Natural stone maintains its structural integrity under extreme heat cycles without off-gassing.

- Freeze-thaw resistance in our Alaska Gray and Arctic Golden series prevents micro-cracking that compromises safety.

- Industry standards now emphasize long-term friction retention over out-of-the-box laboratory performance.

Selecting Textures Based on Application Depth

Choosing between natural and molded textures depends on specific safety requirements and visual goals. Our Rough Series stone is the preferred choice for vertical pool features, waterfall facades, and landscape walls where texture adds both safety and visual drama. For indoor-outdoor transitions, the Flat Series offers a cleaner aesthetic while still providing the subtle, natural grain of real slate to prevent slips.

Molded surfaces are frequently selected for flat walkways where a perfectly level walking plane is mandatory alongside high friction. However, natural stone provides a premium upgrade that increases property value by combining safety with authentic material appeal. We focus on providing dealers with Z-Shape and S-Shape interlocking panels that use CNC diamond-blade precision to ensure these textured surfaces fit tightly, eliminating visible gaps that could catch debris or harbor mold in wet environments.

Does Pool Water Cause Faux Stone to Delaminate?

Bond failure in poolside stone features typically originates from mechanical installation errors and substrate moisture migration rather than the chemical concentration of chlorine or salt.

Industry data through 2026 confirms that while homeowners often blame “harsh chemicals” for falling stones, the reality involves physics and material porosity. Delamination—the separation of the stone veneer from the substrate—occurs when the bond interface fails. While pool water plays a role as a transport medium, the root cause usually hides in the product composition or the application technique used during construction.

Chemical Stability and the Myth of Chlorine Erosion

Maintenance studies clarify that standard chlorine and salt levels do not chemically dissolve the bond between stone and substrate. Balanced pool water lacks the acidity required to etch or eat away at the specialized adhesives used in modern masonry. Instead, delamination appears in areas with existing micro-cracks. Water enters these small fissures, but the chemistry itself does not create the initial failure. Natural stone ledger panels maintain better structural integrity in these environments because they lack the artificial binders and resins found in many faux stone products, which can soften under prolonged saturated conditions.

Installation Defects as the Primary Failure Point

Structural bond failure almost always stems from application errors during the construction phase. Inadequate surface preparation or the presence of air pockets behind the stone creates voids where moisture collects. When this trapped water experiences temperature shifts, it exerts hydrostatic pressure against the back of the stone. Poor bond coat application leads to the “pop-off” effect seen on many exterior pool feature walls. Professionals now favor high-strength epoxy resin adhesives for natural stone panels, as these provide a significantly stronger mechanical grip than standard thin-set, reducing the risk of separation even in high-splash zones.

Porous Backing: The Vulnerability of Concrete-Based Faux Stone

Faux stone products utilize concrete composites that absorb significantly more moisture than natural quartzite or slate. This porosity makes concrete-based stone prone to internal stress during wet-dry cycles. As the material breathes in water and then dries out, the internal structure of the panel weakens over time. Natural stone panels offer a non-porous alternative that prevents water from saturating the core of the material. Current 2026 design trends favor lighter natural stone panels, which reduce the load on the wall and minimize the chance of ground shifting that often triggers bond stress in heavier, cast-concrete imitations.

The Role of Moisture Barriers and Proper Sealing

A comprehensive moisture management strategy protects the ledger panel system from the inside out. External pool applications require a secondary moisture barrier and proper flashing to prevent water from migrating behind the stone panels from the top of the wall or through the coping. Natural stone sealers play a critical role here; a high-quality penetrating sealer protects the face of the stone against mineral deposits and simplifies cleaning. Regular maintenance with pH-neutral cleaners ensures the surface remains free of salt buildup. This proactive approach keeps the adhesive bond dry and secure, preventing the conditions that lead to delamination.

- Ensure 100% mortar coverage to eliminate air pockets behind the stone.

- Use waterproof membranes on the substrate before stone application.

- Select natural quartzite or slate to minimize water absorption.

- Apply penetrating sealers annually to prevent salt crystallization within stone pores.

Aesthetics: Creating a Resort Look with Real Stone Ledger

Natural stone ledger transforms functional pool enclosures into architectural assets by utilizing non-repetitive organic textures and inherent UV stability that synthetic “faux” alternatives cannot replicate.

Visual Authenticity of Real Quarry Stone

Authentic stone ledger provides a luxury aesthetic because it avoids the “pixelated” or repetitive patterns inherent in molded concrete veneers. Each panel displays genuine organic variations in color and grain, ensuring that no two square feet of a pool wall look identical. We achieve high-end consistency by sourcing from the same quarry vein per order, maintaining a 95% hue uniformity while preserving the unique split-face character of the mineral.

- Each ledger panel features genuine quarry stone with organic variations in color and grain.

- Authentic stone adds a sense of permanence and luxury to pool environments.

- Natural materials avoid the repetitive look common in molded concrete veneers.

Strategic Application in Water Features and Spas

Vertical surfaces like waterfall facades and spa surrounds serve as focal points in 2026 luxury designs. Our Rough Series, with thicknesses reaching up to 3.5cm, creates dramatic shadows and depth when water flows over the jagged stone surfaces. To ensure these features look structurally sound, we utilize Z-shaped interlocking panels and CNC diamond-blade precision to camouflage vertical joints and eliminate visible “stepped” gaps.

- The Rough Series creates dramatic shadows and depth when water flows over the jagged stone surfaces.

- Z-shaped interlocking panels ensure seamless transitions around spa corners and curved walls.

- Natural stone ledger maintains its color and integrity when exposed to sunlight and mist from water features.

Balancing Modern Minimalist and Traditional Styles

Designers tailor resort aesthetics by selecting specific stone profiles that match the property’s architectural theme. The Pencil and Flat Series offer clean lines and a linear flow suitable for modern, minimalist pool decks, while earthy slate and quartzite tones like California Gold or Golden Honey complement tropical and rustic landscape designs. Using real marble ledger provides a sophisticated, high-contrast look for upscale residential projects that demand a brighter, cleaner palette.

- The Pencil and Flat Series offer clean lines and linear flow for modern, minimalist pool decks.

- Earthy slate and quartzite tones complement tropical or rustic landscape designs.

- Using real marble ledger provides a sophisticated, high-contrast look for upscale residential projects.

Long-Term Value and Durability in 2026 Design Standards

Investing in real stone enhances property marketability by providing a low-maintenance finish that lasts for decades. Unlike manufactured stone that may fade under intense UV exposure, 100% natural minerals like Quartzite and Slate are UV-stable. This durability ensures the pool area remains pristine for 2026 and beyond. Maintenance remains simple, requiring only occasional cleaning with pH-neutral solutions to keep the surfaces looking fresh and professional.

- Natural stone ledger increases tangible asset value compared to short-lived artificial materials.

- The material resists UV fading, ensuring the pool area looks pristine for 2026 and beyond.

- Low-maintenance surfaces only require occasional cleaning with pH-neutral solutions.

Conclusion

Choosing natural quartzite or slate for pool surrounds prevents the delamination and chemical fading often seen with manufactured stone exposed to salt and chlorine. These materials maintain their structural integrity and slip resistance under constant moisture, ensuring long-term safety and visual appeal for residential and commercial projects. Sourcing directly from the quarry provides the batch consistency needed to create a seamless, resort-style finish that lasts for decades.

Review the Big 10 inventory to see which natural textures best suit your current landscape designs. Contact our team to request a technical catalog or a sample for your next procurement cycle.

Preguntas frecuentes

Can I use stacked stone around a pool?

Yes, stacked stone is a premium choice for pool water features, raised bond beams, and decorative retaining walls. To ensure longevity, it is critical to use a waterproof membrane on the substrate behind the stone and choose a high-quality natural stone or architectural veneer that can withstand constant moisture exposure.

Is salt water bad for stone veneer?

Salt water can cause chloride-induced corrosion and spalling in porous materials. When salt penetrates the stone and crystallizes, it expands, which can lead to surface cracking and structural degradation. Protecting the stone with a high-grade silane-based sealer is essential to prevent salt absorption and maintain the veneer’s integrity.

Does chlorine fade manufactured stone?

Continuous exposure to high concentrations of chlorine can eventually lead to the fading of surface pigments in lower-quality manufactured stone. To prevent this, it is recommended to use stones with “integral color” (where pigment is mixed throughout) and apply a chemical-resistant sealer to block the bleaching effects of pool chemicals.

Best slip-resistant stone for pool walls?

For areas around pool walls and splash zones, natural stones with a textured finish—such as tumbled travertine, slate, or split-face quartzite—are the industry standards. These materials offer high friction coefficients and natural grip, ensuring the surfaces remain safe and stable even when saturated with water.

How to seal stone near water features?

Use a high-performance, breathable silane/siloxane penetrating sealer for stone near water features. This type of sealer creates a hydrophobic barrier deep within the pores to repel water and salts while allowing internal moisture vapor to escape, effectively preventing the spalling and efflorescence common in high-moisture environments.