The choice between thin vs. full bed stone directly dictates the structural load and foundation requirements of a build, meaning an incorrect specification can lead to expensive engineering revisions or significant project delays. If architects or developers underestimate the weight differences between these two options, the resulting structural strain risks building code non-compliance and unforeseen foundation reinforcement costs.

This guide evaluates the physical differences in thickness and cutting methods to help project managers determine the necessity of concrete ledges and additional structural reinforcements. We compare total project costs across material procurement, labor hours, and shipping logistics while assessing environmental impact and design flexibility to create a technical standard for masonry selection.

The Physical Difference: Thickness and Cutting Methods

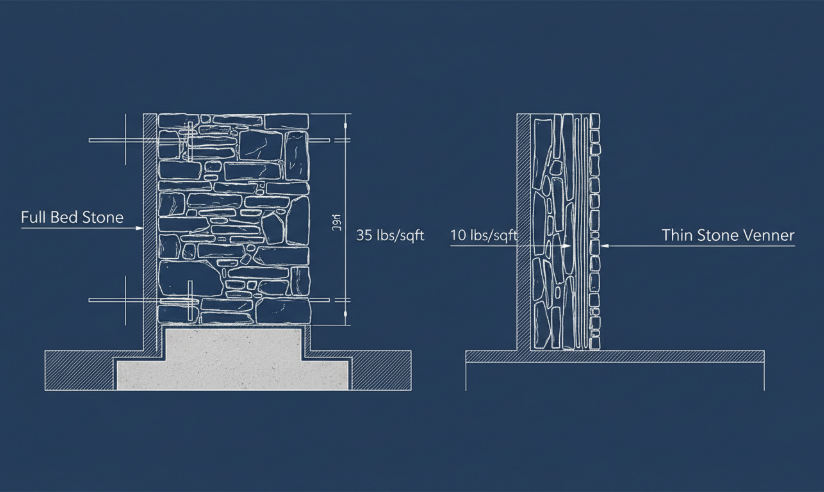

The shift from 5-inch structural masonry to calibrated 1-inch sawn-back veneer reduces dead load by 75%, allowing piedra natural integration on nearly any vertical substrate without the need for traditional foundation ledges.

Modern architecture in 2026 demands a departure from the bulk of traditional stone without sacrificing the tactile quality of natural minerals. Thin stone veneer achieves this through standardized thickness profiles that range from 0.75 to 1.75 inches. Unlike full-bed stone, which requires a 3 to 5-inch depth to maintain structural integrity, thin-cut veneer serves as a high-performance cladding. This calibration allows for specific series applications: the Flat Series provides a slim 0.75-inch profile for minimalist interiors, while the Rough Series utilizes a 1.75-inch depth to create the dramatic shadow lines typically associated with heavy masonry facades.

| Specification | Thin Stone Veneer | Full Bed Stone |

|---|---|---|

| Standard Thickness | 0.75″ – 1.5″ (Calibrated) | 3″ – 5″ (Variable) |

| Weight per Sq. Ft. | 8 – 15 lbs | 35 – 50 lbs |

| Backing Finish | 100% Sawn-Back (Flat) | Natural Split (Uneven) |

| Foundation Required | No (Adhesive Bonded) | Yes (Load-Bearing Ledge) |

Infrared Precision Cutting and Sawn-Back Calibration

Manufacturing precision has evolved to eliminate the irregularities of manual splitting. We utilize infrared cutting technology to ensure every piece meets exact dimensional tolerances, which is critical for achieving tight joints. The sawn-back method creates a perfectly flat rear surface on each stone, maximizing the surface area for epoxy or Type S mortar adhesion. This removes the “voids” common in natural split stone, resulting in a stronger bond and reducing the risk of stone popping due to freeze-thaw cycles. Three-stage quality inspections verify the calibration of these sawn surfaces before they leave the factory, preventing alignment issues that often stall onsite progress.

- Infrared equipment maintains high precision for Z-shaped panels and loose stone alike, ensuring seamless transitions.

- The flat sawn-back reduces mortar consumption by providing a consistent bonding plane.

- Precision edges allow for dry-stack aesthetics without the visible grout lines seen in lower-grade materials.

Structural Load and Weight Reduction Benefits

The primary logistical advantage of thin veneer is the drastic reduction in structural load. While traditional stone blocks weigh upwards of 50 pounds per square foot, thin-cut stone stays between 8 and 13 pounds. This weight efficiency allows installation on standard cement boards or existing masonry surfaces without the need for structural footings, wall ties, or reinforced concrete ledges. For multi-story commercial projects, this weight savings scales significantly, often allowing the project to bypass expensive structural steel reinforcements required for heavy stone facades.

Logistics teams benefit from this efficiency during the procurement phase. A single 2026 standard shipping container can accommodate significantly more square footage of thin veneer compared to full-thickness stone. In markets like the USA where port weight limits are strictly enforced at 17.5 tons, choosing thin veneer can double the coverage area per shipment, effectively halving the per-square-foot shipping cost and reducing the overall carbon footprint of the project.

Structural Support: Do you need a concrete ledge?

Weight dynamics and load distribution dictate whether a masonry project requires a reinforced concrete footing or if the material can be safely bonded directly to the existing wall substrate.

Load Distribution: Thin Stone vs. Full-Thickness Stone

Structural requirements depend heavily on the weight of the material. Traditional full-bed stone carries significant vertical weight, often requiring a structural ledge or footing to transfer the load directly to the foundation. This becomes a critical engineering checkpoint in 2026, as designers distinguish between the 1.25-inch maximum thickness of thin veneer and the 4-6 inch depth of traditional masonry blocks.

| Specification | Full Bed Stone | Top Source Stone Thin Veneer |

|---|---|---|

| Average Thickness | 3 to 5 Inches | 25 to 40 Millimeters |

| Average Weight | 35–45 lbs / sq. ft. | ~13.3 lbs / sq. ft. (65kg/m²) |

| Support Needed | Structural Concrete Ledge | Adhesive Bond to Substrate |

Individually sawn-back thin stone remains light enough for installation on most structurally sound walls without specialized bottom-up support. Because the back of each stone is precision-cut to a flat surface, the bonding agent creates a high-integrity connection that utilizes the tensile strength of the wall itself rather than relying on a foundation ledge for vertical stacking.

Structural Requirements for Concrete Ledges

When projects involve heavy full-bed masonry, specific ledge dimensions and reinforcement detailing ensure long-term stability. Standard industry practices specify ledge heights between 8 and 18 inches and projections ranging from 6 to 10 inches to support the stone’s depth and the required air gap. Concrete failure mechanisms dictate the maximum weight a ledge can safely support during abnormal load conditions.

- Continuous top and bottom reinforcement bars prevent progressive collapse in heavy stone applications.

- U-stirrup configurations provide the necessary shear resistance for ledge projections exceeding 6 inches.

- Proper splicing of reinforcement ensures load redistribution across the entire foundation during seismic events.

Eliminating the Need for New Foundations

The lightweight nature of sawn-back stone systems allows for installation on existing structures without expensive excavation or concrete work. Thin stone attaches directly to cement board, brick, or concrete surfaces, removing the need for a dedicated “brick ledge.” This makes it the preferred choice for retrofitting existing residential or commercial facades where the original foundation was not designed for the weight of 5-inch thick stone.

Contractors save on labor and material costs by skipping the excavation and pouring phases required for traditional stone footings. A bespoke random-lay pattern using loose thin stone distributes weight evenly across the wall surface. As long as the substrate meets structural integrity standards, the 25–40mm profile provides a massive, authentic appearance without the structural penalties of full-depth masonry.

Scale Your Business with Factory-Direct Stone

Total Project Cost: Material vs. Labor vs. Shipping

Project profitability in 2026 hinges on balancing material integrity with reduced site hours and strategic logistics rather than simply chasing the lowest raw material price.

Material expenses typically represent 30–55% of a masonry budget. Selecting natural thin stone provides a higher long-term value than synthetic alternatives, which often face fading and degradation issues within a decade. Using 100% natural quartzite or granite ensures the color and structural integrity remain permanent. When sourcing directly from a quarry factory like Top Source Stone, you eliminate middleman markups that often inflate costs for dealers and wholesalers. This direct-to-source approach helps contractors manage the volatility of raw material prices.

Labor Savings through Installation Efficiency

Labor accounts for 20–40% of total project expenses, making installation speed a critical metric for margin protection. Our individually sawn-back loose stone significantly lowers these expenses by providing a flat, precision-cut surface for bonding. Unlike traditional full-depth stone that requires time-consuming splitting and sorting on-site, sawn-back veneer adheres quickly to substrates like concrete or masonry. This technology reduces on-site labor hours by up to 30%.

| Project Metric | Thin Stone (Sawn-Back) | Full Bed Stone |

|---|---|---|

| Weight (per 1,000 sq ft) | Approx. 7–9 Tons | Approx. 29–40 Tons |

| Structural Requirement | Standard Wall Substrates | Concrete Footings/Ledges |

| Installation Complexity | Bespoke Random-Lay (Fast) | Masonry Intensive (Slow) |

| Total Installed Cost | $15–$45 per sq ft | $30–$100+ per sq ft |

- Authentic Masonry Corner Wraps remove the need for complex miter cuts on-site, which directly cuts down on billable specialized labor hours.

- At 25–40mm thickness, these lightweight stones bypass the need for expensive structural footings or engineered concrete ledges.

- Using high-density quartzite integrity ensures the stone resists moisture, reducing the risk of material failure and subsequent replacement costs.

Logistics Strategy and Global Shipping Impact

Shipping and logistics can add up to 27% to material purchase prices, making efficient packing critical for project profitability. Since thin veneer is roughly one-quarter of the weight of full-bed stone, it allows for significantly higher coverage per container. We utilize a weight strategy tailored to local port standards, such as the 17.5-ton limit common in many USA ports, to avoid overweight penalties and transloading fees.

- Strategic container loading maximizes pallet space, protecting the stone from shifting or breakage during international transit.

- Plywood crates or fumigated solid wood crates ensure the product arrives intact, preventing delays caused by damaged goods at the job site.

- Coordinating bulk shipments directly from the quarry helps stabilize logistics costs against the volatility of the global shipping market.

Design Flexibility: Where Thin Stone Wins

Thin stone veneer eliminates the structural weight penalty of traditional masonry, allowing for 100% natural stone aesthetics in high-rise facades and interior renovations where full-bed stone is physically or economically unfeasible.

Architects and designers frequently choose thin stone veneer because it bypasses the load-bearing requirements of 5-inch thick masonry. By utilizing a thickness of 25–40mm, projects can incorporate heavy-weight aesthetics like granite or quartzite on standard wall substrates without expensive structural reinforcement. This flexibility allows for a seamless transition from exterior landscape walls to interior feature fireplaces, maintaining a consistent design language throughout a property.

Architectural Versatility Across Styles

Natural stone textures provide a unique character that human-made, concrete-based alternatives cannot replicate. We source materials like slate, quartzite, and marble from specific quarry veins to ensure that every order maintains color harmony while preserving the zero-repeat natural variation expected in high-end architecture.

- Designers use these materials for diverse applications, including interior accent walls, kitchen backsplashes, and expansive commercial facades.

- The lightweight profile enables the use of stone in upper-story installations and retrofits where adding a concrete ledge is impossible.

- Natural stone adapts to various styles, from rustic mountain-style lodges to modern, minimalist retail environments.

Precision Engineering for Sawn-Back Efficiency

Modern manufacturing utilizes precision cutting to create a 100% sawn-back finish. This technical advancement provides a perfectly flat bonding surface, which increases the contact area for adhesives and reduces on-site labor costs by roughly 30%. Unlike irregular full-bed stones, sawn-back veneer allows masons to set pieces faster with higher bond strength.

To achieve full-depth visual integrity, we supply matching L-shaped corner wraps. These pieces wrap around pillars and wall ends to mimic the appearance of massive, structural stone blocks. This bespoke random-lay pattern ensures the final installation is indistinguishable from traditional masonry, providing a professional finish without the bulk.

Specialized Series for Targeted Impacts

Curated product lines allow for specific tactile and visual depths tailored to custom project requirements. By selecting stones based on their surface profile, designers control how light and shadow interact with the wall surface.

- The Flat Series provides clean lines and subtle textures for contemporary, low-profile interior designs.

- The Rough Series creates dramatic shadows and deep dimensions, ideal for rugged exterior landscapes and large-scale feature fireplaces.

- The Pencil Series utilizes thin, linear stone strips to create a sense of motion and sophisticated detail in luxury lobbies and residential suites.

Property Value and Aesthetic Longevity

Using authentic thin stone is a recognized upgrade in the 2026 real estate market. Natural stone is UV-resistant and will not fade, peel, or discolor over decades of exposure, unlike manufactured concrete products. High-density quartzite and granite offer superior resistance to moisture and staining, ensuring the stone maintains its structural integrity in harsh climates.

The non-combustible nature of 100% piedra natural also makes it a functional and safe choice for modern fireplace surrounds. Real marble and slate are perceived as premium materials that contribute directly to the resale value of commercial and residential developments, offering a lifetime of durability that synthetic alternatives cannot match.

Environmental Impact and Material Efficiency

Thin stone veneer reduces the carbon intensity of architectural projects by slashing logistics weight and eliminating the need for cement-heavy structural supports.

Carbon Footprint Reductions in Logistics

Weight determines the environmental cost of any cladding material. Thin stone panels typically weigh between 8 and 13 pounds per square foot, a massive reduction from the 35–45 pounds required for full bed stone. This lower mass allows distributors to ship significantly more square footage per container, which cuts the total fuel consumption and carbon emissions per project unit.

- Shipping higher volumes of material per container compared to full-thickness stone lowers the carbon cost for both global and local transit.

- Lighter materials eliminate the need for heavy structural concrete ledges, which reduces the total cement usage and associated CO2 emissions of the building.

- Reduced physical weight simplifies on-site handling, decreasing the reliance on heavy machinery during the installation phase.

Embodied Carbon and Material Longevity

Natural stone maintains a lower chemical energy profile than manufactured concrete alternatives. While concrete veneers require high-heat curing and synthetic pigments that degrade over time, natural quartzite and slate rely on mechanical fabrication. The climate-tested durability of 100% quarried stone prevents UV fading and weathering, ensuring the product remains functional for decades.

- Natural stone panels bypass the high-heat curing and chemical pigmenting processes common in manufactured stone production.

- The inherent durability of quarried material prevents UV fading, extending the product lifecycle and reducing the need for replacements.

- Long-term material stability reduces the environmental cost associated with frequent renovations and demolition waste.

Resource Efficiency and Waste Management

Advanced fabrication focuses on maximizing the yield from every raw block. Precision infrared cutting equipment turns raw stone into usable panels with minimal scrap, ensuring that every pound of stone shipped serves a functional purpose on the wall. This high-yield methodology, combined with 100% sawn-back technology, ensures a flat bonding surface that minimizes mortar waste during installation.

- Precision cutting equipment ensures high-yield material usage, transforming raw blocks into usable panels with minimal manufacturing scrap.

- Modern manufacturing facilities utilize closed-loop water filtration systems to recycle the water used during the stone-cutting process.

- Ethical quarrying practices prioritize land reclamation and the responsible management of all stone by-products.

Conclusion

Selecting the right stone format determines the structural requirements and long-term viability of a project. Sawn-back thin stone veneer offers a practical path to achieving a natural masonry finish without the need for concrete ledges or heavy foundation support. These efficiencies reduce both material shipping costs and on-site labor hours.

Review your specific wall substrates to see how thin stone veneer can streamline your building process. Contact our team to receive a technical catalog or to discuss sourcing for your upcoming developments.

Preguntas frecuentes

Is thin stone real stone?

Yes, natural thin stone veneer is 100% real stone. It is harvested from the earth just like traditional full-thickness stone, but it is precision-sawn to a thickness of ¾” to 1.5″. This distinguishes it from “manufactured stone,” which is a synthetic product made from colored concrete.

Does thin stone veneer need a foundation?

No, thin stone veneer does not require a structural foundation, ledge, or footer. Because of its lightweight profile, it is classified as an adhered veneer, meaning it is supported by the wall itself. This makes it an ideal choice for renovations where an existing foundation cannot support the weight of full-bed stone.

Which is more expensive: thin or full bed stone?

While the raw material cost per square foot for thin veneer can sometimes be higher due to the precision sawing process, the total project cost is typically much lower. Thin stone is significantly cheaper to ship due to its reduced weight and requires far less labor and time to install, resulting in overall savings for most commercial and residential projects.

Can thin veneer be used for retaining walls?

Yes, thin veneer is an excellent choice for facing retaining walls made of concrete or CMU (cinder block). It provides the aesthetic beauty of a solid stone structure without the massive footprint and structural complexity required by full-thickness stones, though the underlying wall must be properly engineered to handle the load.

How long does full bed stone last vs veneer?

Both full bed and thin natural stone are incredibly durable and can last for decades or even a century. Full bed stone (3-5″ thick) offers superior resistance to heavy physical impacts due to its mass. Thin veneer is equally weather-resistant, though its longevity is tied to the quality of the mortar bond and the integrity of the substrate it is adhered to.

Is thin stone harder to install?

No, thin stone is generally considered much easier and faster to install than full bed stone. Its sawn-back technology allows for a flat surface that adheres easily to various substrates. Because it is lightweight, it eliminates the need for wall ties and heavy lifting equipment, making it the preferred option for modern construction and DIY applications.