Deciding between stacked stone panels vs individual stones serves as the primary pivot point between maintaining a profitable construction schedule and facing the ballooning labor costs of traditional masonry. Selecting the wrong material for a specific substrate or climate zone often results in installation delays and structural failures that threaten project timelines. Efficient crews prioritize systems that minimize waste while meeting the strict aesthetic standards demanded by modern architectural specifications.

We analyze the mechanical differences between modular panel systems and loose veneer to help you choose the right application for your specific wall type. This technical review covers installation speed benchmarks, seam management techniques for corners, and the material costs associated with both DIY and professional-grade projects. You will find a clear comparison of realism against assembly time to ensure the final finish aligns with your site requirements and budget constraints.

Panels vs. Pieces: What’s the Real-World Difference?

The choice between loose stone and modular panels is no longer just about aesthetics; it is a strategic decision balancing rising masonry labor costs against the need for structural efficiency in modern building envelopes.

Installation Speed and Labor Efficiency

Crews install interlocking Z-shaped panels significantly faster than individual stones, often cutting labor time by 40% to 60%. This efficiency stems from the pre-engineered nature of the panels, which eliminates the time-consuming process of hand-sorting and fitting irregular loose pieces. By removing the need for highly specialized masonry skills, these systems allow general contractors to maintain tight 2026 construction schedules even when skilled artisans are in short supply.

- Modular Z-shape systems utilize a “male-female” connection that automates alignment and reduces onsite adjustments.

- Rapid installation directly improves project profitability by reducing the number of billable days on a job site.

- Engineered panels enable a “plug-and-play” workflow that simplifies project management for large-scale commercial facades.

Structural Weight and Foundation Requirements

The physical format of the stone dictates the necessary wall preparation and underlying support. Individual full-thickness stones carry immense weight and often require concrete ledges or specialized reinforcement to prevent structural wall failure. Natural stacked stone panels, however, weigh between 8 and 13 lbs per square foot. This lightweight profile typically eliminates the need for structural footings or complex wall ties, making them a safer and more versatile option for a variety of substrates.

This reduction in dead load allows for the application of natural stone on standard cement boards and residential exterior facades that were not originally designed for heavy masonry. For interior feature walls, this means the stone can often be applied directly to properly prepared surfaces without expensive structural retrofitting.

Aesthetic Control and Visual Consistency

Choosing between panels and loose pieces fundamentally changes the texture and seam visibility of the wall. Panels provide a consistent, repeatable texture across large surfaces by utilizing natural stone cut to precise specifications. While some worry about repeating patterns, high-quality interlocking systems hide vertical seams more effectively than traditional modular blocks, creating a continuous architectural flow across the facade.

- Individual stones offer maximum creative freedom, allowing masons to vary depth and spacing for a one-of-a-kind, artisanal look.

- Precision CNC diamond-blade edges on panels ensure a tight fit that minimizes gaps and prevents the “stepped” look seen in lower-grade materials.

- Natural stone panels maintain authentic variation because the raw material is sourced from the same quarry layer, preventing patchy or mismatched sections.

Total Project Investment and Cost Analysis

A thorough financial analysis reveals that the true cost of stone is the installed price, not the pallet price. Individual loose stones often have lower upfront material costs, but the high price of skilled masonry labor frequently drives the total budget well beyond that of a panel system. Panels represent a higher initial material investment, but they lower the total project cost by reducing billable hours and minimizing onsite waste.

Beyond the initial build, natural stone panels offer superior long-term value compared to manufactured alternatives. They possess inherent UV stability and resistance to fading, which is critical for maintaining property value in high-exposure environments like the United States or the Middle East. Choosing real stone over “faux” options ensures the facade remains a permanent asset rather than a maintenance liability.

What Are Stacked Stone Panels? (Pros, Cons, Best For)

Stacked stone panels modernize traditional masonry by bonding natural stone strips into modular, interlocking units that reduce installation timelines by up to 80% compared to loose veneer.

The Anatomy of an Interlocking Panel System

These systems utilize thin strips of natural minerals like slate, quartzite, or marble, which workers bond together to form a single modular unit. Modern manufacturing in 2026 relies on high-strength epoxy resins to secure these stones to either a fiberglass mesh or a lightweight concrete backing. This construction ensures the unit maintains structural integrity during transit and installation.

Standard engineering focuses on a Z-shaped interlocking design. This specific geometry hides vertical seams by allowing the panels to nest together, creating a continuous architectural surface. Current industry standards prioritize lightweight profiles, with panels typically weighing between 8 and 13 pounds per square foot, making them manageable for a single installer.

Primary Advantages for Modern Construction

The primary driver behind panel adoption is the radical increase in installation speed. Contractors report that panel systems allow for coverage of 40-50 square feet per day, a significant jump from the slower pace of individual stone placement. This efficiency directly lowers total project costs by minimizing expensive onsite labor hours.

- Weight reduction often eliminates the need for expensive structural footings or metal wall ties required by full-thickness stone.

- Natural stone surfaces offer permanent UV stability, ensuring the facade color does not fade or “bleach” like painted concrete imitations.

- Precision-cut edges from CNC diamond blades ensure a tight fit that mimics the look of professional dry-stack masonry.

Key Limitations and Technical Considerations

While these panels offer high performance, they are not a standalone waterproofing solution. Natural stone is water-resistant, but the joints between panels can allow moisture penetration. Exterior projects require a dedicated moisture-management system, including a weather-resistant barrier and drainage plane, to protect the underlying structure.

Substrate preparation is non-negotiable. Interior drywall lacks the shear strength to support stone weight, so installers must use cement board overlays. Additionally, the modular nature of panels can sometimes lead to visible repeating patterns if the installer fails to stagger the joints or mix panels from different crates during the layout phase.

Optimal Applications for Panelized Stone

Fireplace surrounds represent the most common application because natural stone is inherently non-combustible. The panels withstand high heat without off-gassing, providing a safe and durable finish for residential living spaces. Commercial sectors also utilize these systems for lobby feature walls and exterior facades where a high-end aesthetic must meet a tight construction schedule.

Residential accents like kitchen backsplashes and patio walls benefit from the diverse textures available in the market. Many designers choose the “Rough” series for outdoor water features to maximize shadow lines, while the “Flat” series offers a cleaner, more contemporary look for interior transitions. Matching L-shaped corners are essential for these projects to ensure a professional wrap-around finish on pillars and wall ends.

Boost Profits with Fast-Installing Ledger Panels

What Are Individual Stones (Loose Veneer)? (Pros, Cons, Best For)

Individual stone veneer represents the pinnacle of masonry authenticity, offering a bespoke, hand-laid finish that avoids the repetitive patterns inherent in modular systems.

Design Flexibility and Handcrafted Authenticity

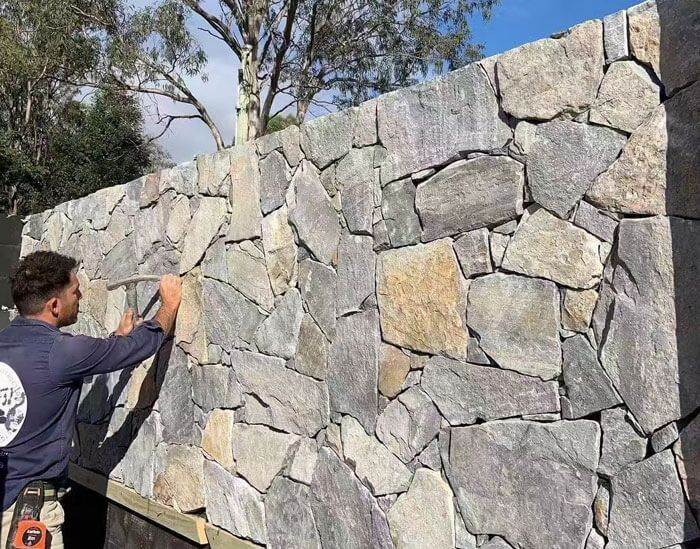

Loose veneer consists of separate pieces of natural stone that masons install one by one. This approach grants total control over the final aesthetic, as the mason determines the placement, orientation, and spacing of every single unit. Because no two stones are identical and there is no fixed panel cycle, the resulting wall is a unique architectural feature that avoids the “stepped” look sometimes found in lower-quality panel installations.

- Every project results in a unique pattern because masons select and place stones individually without repeating cycles.

- Masons can adjust grout line widths and stone orientations to match specific architectural styles, from rustic European to modern rubble.

- Using 100% quarried stone ensures a permanent color that never fades, maintaining the property’s aesthetic and market value into 2026 and beyond.

Skilled Labor and Extended Project Timelines

The primary drawback of individual stone veneer involves the high cost of specialized labor and the time required for placement. While Top Source Stone panel systems prioritize speed, loose veneer is a slow, methodical process. A skilled mason might only cover 25 to 35 square feet per day, compared to the 50+ square feet possible with pre-assembled panels. This labor intensity often doubles the installation portion of the project budget.

- Installation takes significantly longer than panelized systems, which may cause delays in meeting tight 2026 construction schedules.

- Finding skilled masons capable of laying loose veneer requires higher budgets—typically $15 to $25 per square foot—compared to general labor.

- The process generates more on-site waste as masons must trim and shape individual pieces to fit the wall perfectly.

Structural Support and Weight Considerations

Traditional individual stones are often heavier than thin-cut panels. This weight adds up quickly across a large facade, requiring specific structural preparations that lightweight veneers bypass. Engineers must evaluate the wall substrate and the foundation to ensure they can handle the concentrated load of hand-stacked masonry without settling or cracking over time.

- Full-thickness loose stones frequently require structural footings or brick ledges to support the cumulative weight.

- Individual stone installations lack the “no footing” benefit of the 8-12 lbs/sqft range found in modern panel systems.

- Engineers must verify that the wall substrate can handle the concentrated load before installation begins.

Optimal Use Cases for Heritage and Luxury Projects

Loose veneer serves as the standard for high-end applications where authenticity outweighs the need for speed. For historical restorations where the new stone must match existing 19th-century masonry, or for ultra-luxury estates with complex curved geometry, individual stones are the only viable choice. They allow for a “found-in-nature” appearance that even the most advanced interlocking panels struggle to replicate on tight corners or radiused walls.

- Bespoke luxury estates utilize loose veneer to create an organic appearance that panels cannot perfectly replicate.

- Heritage restoration projects require individual stones to accurately match historical masonry techniques and existing stone structures.

- Individual stones work best for curved walls or complex geometric features where rigid rectangular panels are difficult to cut and fit.

The Stone Guru’s Showdown: Speed, Cost, and Realism

Modular panel systems disrupt traditional masonry timelines by automating the stone-setting process, effectively doubling daily square-footage output while slashing labor overhead.

Installation Speed: Rapid Deployment vs. Traditional Masonry

Stacked stone panels utilize an interlocking Z-shape system that cuts installation time by roughly 50% to 80% compared to loose veneer. This pre-assembled format allows crews to cover large square-footage areas quickly, a critical advantage for meeting tight 2026 project deadlines. By simplifying the application, contractors can deploy general crews to achieve professional results that once required master masons.

While traditional mortar-laid stone requires precise, one-by-one placement and weather-dependent curing, Pierre de source supérieure panels allow for all-weather installation. This rapid deployment eliminates the bottleneck of specialized masonry skills, ensuring that large-scale exterior facades or commercial interiors move from substrate to finished wall in a fraction of the time.

Total Project Cost: Labor Savings and Structural Requirements

Evaluating financial impact requires looking beyond material prices to labor and structural preparation. Reduced labor hours directly increase project profitability for contractors and lower total costs for property owners. Panels typically require only $10-15 per square foot in installation labor, whereas individual stones often demand $15-25 due to the intensive hand-sorting and setting required.

| Performance Metric | Panneaux en pierre empilés | Individual Stones (Loose) |

|---|---|---|

| Daily Install Rate | 40-50 sq. ft. per person | 25-35 sq. ft. per person |

| Structural Load | Lightweight (8-12 lbs/sq.ft) | Heavy (Requires footings) |

| Labor Skill Level | General Contractor / DIY | Specialized Master Mason |

| Total Installed Cost | Lower (High speed, low labor) | Higher (Slow speed, high labor) |

Lightweight panels eliminate the need for expensive structural footings or wall ties often required by full-thickness stone. Direct manufacturer sourcing from Top Source Stone further improves the cost-to-value ratio for large-scale builds, as we provide factory-direct pricing on 100% natural stone materials including slate, quartzite, and granite.

Visual Realism: Natural Texture and Interlocking Precision

Modern manufacturing ensures that efficiency does not come at the expense of authentic stone aesthetics. Natural stone panels offer unique, unrepeatable textures that outperform pigment-based manufactured alternatives, which often fade or look repetitive. We utilize CNC diamond-blade edges to ensure precision dimensions, creating seamless transitions that hide visible joints.

To maintain a rugged, hand-laid appearance, these panels use a high-strength epoxy resin bonding that prevents stone fallout. By sourcing from the same quarry vein per order, we maintain 95% hue uniformity, preventing the “patchy” look common in low-grade bulk imports. The result is a hand-assembled natural stone finish that provides the architectural depth of a traditional wall with the technical precision of a modular system.

Installation Pro Tip: The Flat Wall vs. The Complex Corner

Precision in wall geometry selection and corner management determines whether a natural stone project achieves architectural seamlessness or suffers from amateurish vertical “stair-stepping” patterns.

Maximizing Efficiency on Standard Flat Surfaces

Large-scale flat walls benefit most from the 6” x 24” interlocking Z-panel system. This engineered format streamlines the layout process by eliminating the need for precise placement of individual loose stones. The interlocking edges utilize a male-female connection that camouflages vertical joints, creating a continuous texture across the entire facade. Installers achieve the highest efficiency by staggering the panels at 1/3 or 1/2 offsets, which breaks up repetitive patterns and ensures the natural variations in the Slate or Quartzite series flow cohesively.

- Interlocking formats eliminate visible grout lines and substrate exposure.

- Lightweight designs (8-13 lbs/sqft) allow direct application to masonry or cement board without structural base footings.

- Strategic staggering ensures natural stone color shifts appear organic rather than patchy.

Simplifying 90-Degree Angles with L-Shaped Corners

Corners represent the primary failure point in traditional stone masonry, often requiring hours of manual mitering and diamond-blade cutting. Pre-fabricated L-shaped corner pieces remove this complexity by providing a factory-finished 90-degree angle that mimics full-thickness stone blocks. These matching pieces ensure that the texture and color remain synchronized at wall transitions, providing a professional wrap-around finish that resists “stair-stepping.”

| Installation Component | Technical Mechanism | Project Impact |

|---|---|---|

| Interlocking Z-Panels | Male-Female CNC Precision Joints | 60% faster install vs. loose stone |

| L-Shaped Corner Pieces | Pre-fabricated 90-degree miter | 50% reduction in corner labor hours |

| High-Strength Epoxy | Chemical Bonding to Substrate | Eliminates stone shedding and delamination |

Substrate Preparation and Moisture Management

Structural integrity starts with the underlying surface. Exterior installations must include a dedicated moisture barrier and flashing system to manage water runoff and prevent retention behind the stone veneer. Indoors, drywall lacks the structural capacity to support natural stone weight; installers must use cement backer board. Using high-strength epoxy adhesive specifically formulated for natural minerals ensures a permanent bond that resists the temperature fluctuations found in Northern climates.

- Apply epoxy adhesive with a notched trowel for 100% back-side coverage.

- Use a moisture barrier for exterior facades to prevent freeze-thaw damage.

- Ensure the substrate is clean and free of paint or sealants before bonding.

Selecting the Right Series for Wall Geometry

Designers choose specific panel profiles to manipulate shadow lines and visual depth. The Flat Series offers clean lines and subtle textures suited for modern interior feature walls. In contrast, the Rough Series features stones up to 3.5cm thick, creating dramatic shadows that mask minor substrate imperfections on large exterior facades. The Pencil Series provides a linear, high-detail aesthetic that suits high-end commercial lobbies where architectural precision is the priority.

- Rough Series panels hide wall variations with heavy 3D textures.

- Flat Series panels provide a sleek, low-profile finish for tight interior spaces.

- Pencil Series emphasizes horizontal lines for contemporary architectural styles.

The Seam Problem: How to Hide Panel Seams

Achieving a monolithic stone surface depends on a combination of precision-engineered geometry and systematic installation workflows that disrupt the human eye’s ability to track modular boundaries.

Interlocking Z-Shape Panel Geometry

Modern stacked stone panels utilize a Z-shaped interlocking design to break up straight vertical lines that typically signal a modular installation. This Z-shape geometry allows panels to fit together like puzzle pieces, hiding the transition between units. At Top Source Stone, we use CNC diamond-blade precision to ensure that each panel edge meets its neighbor with minimal gap tolerances. Precision infrared cutting equipment eliminates the visible “stepped” gaps common in lower-grade products, maintaining the illusion of a hand-laid stone wall by concealing the installation substrate entirely.

| Panel Type | Seam Concealment Method | Visual Continuity |

|---|---|---|

| Standard Rectangle | Butt-joint alignment | Moderate; visible vertical lines |

| Z-Shape / S-Shape | Male-Female Interlocking | High; camouflaged modular borders |

| Loose Stone Veneer | Manual stone-by-stone layout | Maximum; no repeating joints |

Staggered Installation Patterns

Installers prevent visible “stacking” by offsetting the vertical joints of each row, mirroring traditional masonry techniques. We recommend starting every other row with a half-panel to ensure that vertical seams never align across different levels. Staggering the joints disrupts the human eye’s ability to track repeating patterns or modular borders. To further enhance this, using L-shaped corner pieces eliminates the need for miter cuts at transitions, which often create the most prominent visible seams. These pre-fabricated corners ensure texture and color synchronization continue around the wall without a break in the pattern.

Material Sorting and Color Calibration

Natural stone variations can highlight seams if one panel is significantly darker or lighter than its neighbor. We source our materials from the same quarry vein per order to maintain 95% hue uniformity, yet natural shifts still exist. Professional installers pull panels from multiple crates simultaneously during installation to blend these natural color shifts across the entire surface. Pre-laying the pattern on the floor allows installers to identify and reposition high-contrast panels before adhering them to the wall. This calibration step prevents “patchy” sections that draw attention to the individual panel borders.

Professional Finishing and Sealant Application

Applying specific finishing touches after the stones are set helps unify the wall and mask any remaining hairline gaps. Use color-matched stone dust or specialized epoxy resins to fill small voids at the junction of two panels. After the adhesive fully cures, applying a high-quality natural stone sealant provides a uniform sheen and deepens the stone’s color. This sealant creates a cohesive visual layer that draws focus to the stone’s natural texture rather than the technical panel borders, especially in exterior applications where UV stability and moisture resistance are required.

The Final Verdict: Which One Should You Actually Buy?

The decision rests on a simple trade-off: choose interlocking panels to mitigate high labor costs and tight schedules, or select individual stones when the architectural design demands artisan customization and non-standard geometries.

Choose Stacked Stone Panels for Efficiency and Lower Structural Impact

Panels serve as the primary solution for projects facing strict deadlines or structural weight constraints. In the current construction landscape, the ability to install 40 to 50 square feet per day per person transforms the profitability of a job. Interlocking Z-shaped panels, engineered with CNC diamond-blade precision, allow crews to bypass the need for master masons, as the “male-female” connection system handles the alignment and seam concealment automatically.

- Deploy Z-shaped interlocking systems for fast turnarounds where specialized masonry skills are unavailable.

- Utilize lightweight panels (8–13 lbs per square foot) for interior drywall or exterior retrofits where adding a concrete footing is structurally impossible.

- Prioritize panels for large-scale commercial facades to ensure consistent quality control and a uniform aesthetic across expansive surfaces.

Select Individual Stones for Maximum Layout Control and Artisan Projects

Loose veneer provides the total design freedom required for unique architectural shapes that modular systems cannot navigate. When a project involves complex curves, organic pillars, or heritage restorations, individual stones allow the installer to chip, shape, and place every piece to fit the specific contours of the structure. This “stone-by-stone” approach eliminates the risk of repeating patterns and ensures a truly handcrafted finish.

- Opt for individual pieces when the wall design includes tight radii or non-standard angles that interlocking edges cannot accommodate.

- Specify loose stone for high-end residential projects where the client prioritizes a unique, authentic masonry aesthetic over speed.

- Budget for significantly higher labor costs and extended timelines, as hand-stacking requires specialized skills and more hours on-site.

Final Criteria for Selecting the Right Stone System in 2026

Success in 2026 requires balancing the desire for customization with the reality of the labor market. While individual stones offer unmatched character, the 50% to 90% reduction in labor costs provided by natural stone panels often dictates the project’s financial viability. We recommend natural stone over manufactured concrete alternatives regardless of the format; real quartzite and slate maintain their color and integrity under UV exposure far better than painted cement imitations.

- Evaluate the total installed cost; panels often carry a higher material price but yield a lower total bottom line due to massive labor savings.

- Check material composition to ensure long-term value and freeze-thaw resistance, especially in Northern climates.

- Consider the availability of matching L-corners; using pre-fabricated corners with panels ensures a professional wrap-around finish without on-site miter cutting.

Conclusion

Choosing between stacked stone panels and individual stones determines the balance of installation speed and aesthetic customization. Panels offer a streamlined, modular approach that reduces labor hours, while individual stones allow for unique, hand-laid textures. Selecting the right format ensures the project meets both budget requirements and long-term durability standards.

Review your project dimensions and labor availability to determine which format fits your timeline best. If you need technical specifications or a full catalog of natural stone options, contact our team to discuss sourcing for your next project.

Foire aux questions

Are stacked stone panels cheaper than individual stones?

While the material cost for panels is often higher per square foot than individual stones, panels are generally cheaper for the total project. The pre-engineered design drastically reduces professional labor costs, which usually accounts for the largest portion of a masonry budget, making the overall installation more economical.

Is it faster to install panels?

Yes, installing panels is significantly faster. Pre-engineered panel systems reduce installation time by 40% to 60% compared to traditional individual stone placement. This efficiency stems from the ability to install large, interlocking sections at once rather than fitting, leveling, and adhering hundreds of individual small stones.

Can you see the seams on stacked stone panels?

Modern stacked stone panels utilize interlocking “Z-shaped” or staggered designs specifically engineered to mask joints. When installed correctly, the seams are virtually invisible to the naked eye. However, seams may become visible if the panels are poor quality or if the installer fails to properly level and tight-fit the edges during the application.

Which one looks more realistic?

Individual stones provide the highest level of realism and design authenticity. Because each piece is placed manually, there is no risk of repeating patterns or unnatural “grid” lines. While high-end panels look incredibly convincing, individual stones offer the creative flexibility to customize color distribution and texture for a truly unique, natural masonry finish.

Which is better for a DIYer?

Stacked stone panels are the ideal choice for DIYers. They are designed for user-friendly installation, requiring fewer specialized tools and much less experience with mortar and stone-sorting than individual pieces. The modular nature of the panels ensures a level, professional-looking result even for those with limited masonry skills.