Domande frequenti

Why are there visible gaps between my Alaska Gray panels after installation?

Gaps between panels are common due to natural stone variation and installation challenges. For exterior installations in climates like Michigan, use a sanded grout or polymer-modified mortar that matches the panel color to fill gaps. Avoid silicone caulk for exterior applications as it may fail during freeze-thaw cycles. For interior applications, grout caulk in a matching color can help minimize the appearance of gaps.

Do Alaska Gray marble panels need to be sealed, and how often?

A: Yes, these natural marble panels must be sealed to prevent water absorption, staining, and freeze-thaw damage. Apply a penetrating stone sealer before installation and reseal every 12-24 months depending on exposure. For exterior applications, sealing is critical to prevent moisture infiltration that can cause mold and structural damage behind the panels.

Can I use Alaska Gray panels around a fireplace or high-heat areas?

Alaska Gray marble panels are suitable for fireplace surrounds when properly installed with appropriate adhesive and substrate preparation. Ensure adequate clearance from direct heat sources and follow local building codes for adhered masonry veneer. The natural marble construction provides good heat resistance compared to manufactured alternatives.

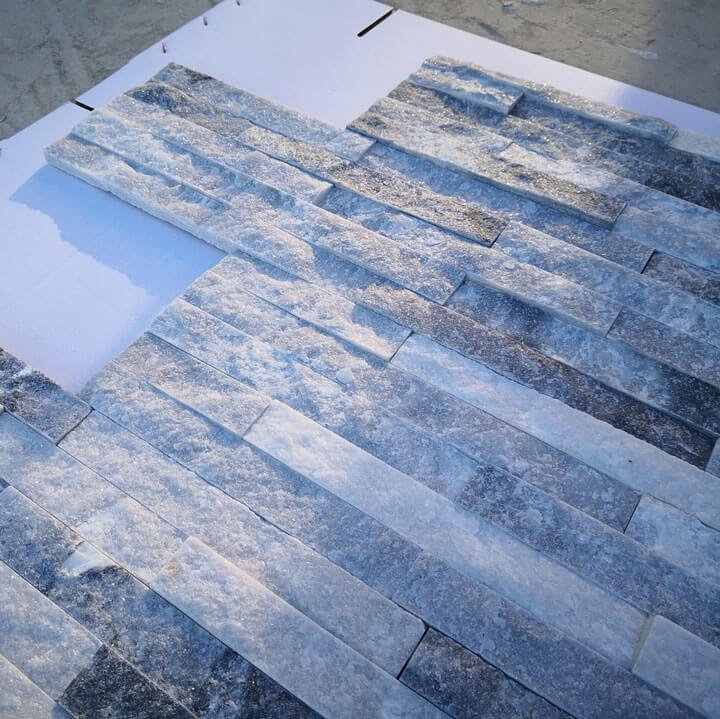

What’s the difference between Alaska Gray regular and multi-finish panels?

Regular Alaska Gray features consistent split-face texture, while Alaska Gray Multi combines different finishes (split face, honed, and 3D textured surfaces) on the same panel. Multi-finish provides more visual variety but requires more careful installation to align different texture heights properly. Both maintain the same gray and white marble coloration.

Why does my contractor say grout-free installation isn’t possible with these panels?

While Alaska Gray panels are marketed as “grout-free,” real-world installations often require gap filling due to natural stone variations and wall irregularities. Professional masons typically recommend planning for mortar joints or sealant gaps, especially for exterior installations or when maintaining perfectly level runs across uneven surfaces.

Are these panels suitable for shower applications?

Alaska Gray marble panels can be used in shower applications when properly sealed and waterproofed. However, marble is more maintenance-intensive than porcelain or ceramic in wet areas. Apply a high-quality penetrating sealer and maintain regular resealing schedules to prevent water damage and staining.

What causes the “glue lines” visible on some Alaska Gray panels?

The visible adhesive lines are from the factory assembly process where individual stone pieces are bonded together to create the panel. This is normal for manufactured stone panels. The adhesive may become more visible over time due to weathering or if panels get wet during installation.

How do I prevent moisture problems behind Alaska Gray veneer on exterior walls?

Proper moisture management requires a water-resistant barrier, drainage plane, and adequate flashing around penetrations. Many stone veneer failures occur due to inadequate moisture barriers that allow water infiltration behind panels, leading to mold, rot, and structural damage. Always follow building codes for adhered masonry veneer systems.

Can I install Alaska Gray panels as a DIY project?

While possible for experienced DIYers, Alaska Gray panel installation requires proper substrate preparation, adhesive selection, and alignment techniques. Poor installation can result in gaps, moisture infiltration, and premature failure. Consider professional installation for exterior applications or areas exposed to moisture.

What should I do if my Alaska Gray panels are staining or showing water spots?

Staining usually indicates insufficient or failed sealer protection. Clean the affected area with appropriate stone cleaner, allow to dry completely, then reapply penetrating sealer. For persistent stains, professional stone restoration may be required. Regular maintenance and prompt spill cleanup are essential for marble surfaces.