Preventing installation failures in stone veneer cladding is a critical priority for commercial developers facing rising liability costs and strict building safety codes. When stone panels detach from a facade, the resulting remediation expenses and legal risks often compromise the financial viability of a project. Building owners and contractors must address the underlying mechanical causes of bond loss to ensure the long-term durability of both faux and natural stone applications.

This guide breaks down the physics of bond degradation, comparing the different thermal expansion rates of synthetic composites and natural minerals. We evaluate how moisture retention and substrate porosity dictate mortar selection for high-load vertical walls. By reviewing multi-story cladding case studies and adhesive performance requirements, these sections provide a technical framework for maintaining structural integrity in heavy veneer systems.

Common Causes of Stone Veneer Bond Failure

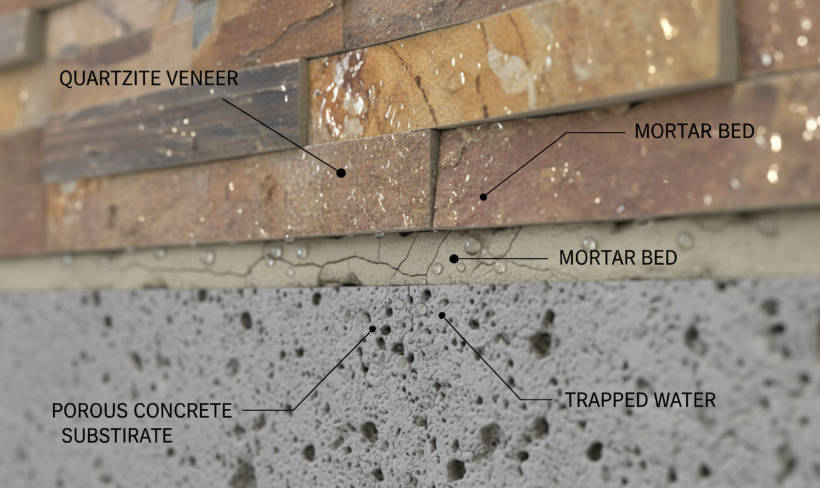

Most veneer delamination occurs because the wall assembly fails to act as a holistic system, allowing trapped moisture to transform from a minor nuisance into a structural wedge during thermal cycles.

Effective cladding performance requires more than high-quality stone; it demands a managed environment behind the stone. In 2026, building envelope standards emphasize that water penetration is an inevitability rather than a possibility. When installers treat stone veneer as a waterproof barrier rather than a reservoir cladding, they inadvertently set the stage for systemic bond failure.

Inadequate Moisture Management and Drainage

Water penetration behind the stone veneer system remains the primary driver of bond failure in 2026 building envelope standards. Because mortar and cement-based substrates are inherently permeable, moisture eventually migrates through the stone or joints. Without a dedicated drainage plane or a ventilated air gap, this moisture becomes trapped against the substrate, leading to hydrostatic pressure that physically pushes the stone away from the wall.

- Permeable mortar and cement allow water to seep behind the veneer, where it often becomes trapped without a dedicated drainage plane.

- Trapped moisture creates a breeding ground for mold and leads to structural wood rot in the underlying substrate.

- Failure to install proper weather-resistant barriers and flashing systems prevents the wall assembly from drying effectively.

Improper Expansion Joint and Anchorage Detailing

Design-related failures often occur when the veneer system cannot accommodate natural structural movements. Buildings are dynamic; they settle, sway, and vibrate. If the rivestimento in pietra is applied as a rigid sheet without strategic breaks, the internal stresses will eventually exceed the shear strength of the mortar bond. At Pietra sorgente superiore, we emphasize that even 100% natural quartzite requires precision detailing at corners and transitions to survive these shifts.

- Undersized expansion joints, frequently narrower than 1/4 inch, fail to absorb the shifting loads of the building.

- Rigid anchorage connections lack the necessary flexibility to handle differential movement between the stone and the substrate.

- Incomplete joint depth detailing leads to stress concentrations that eventually force the stone to separate from the wall.

Mortar Application and Bonding Deficiencies

Poor installation techniques during the masonry process significantly compromise the long-term adhesion of the stone. We often see “spot bonding” where installers only apply mortar to the center of the stone. This creates voids that act as water reservoirs and reduce the contact intimacy required for a permanent bond. While polymer-modified mortars offer superior grip, they lose critical strength when they remain saturated for extended periods.

- Insufficient mortar coverage, often achieving only 60% to 90% contact intimacy, leaves voids that weaken the overall bond.

- Polymer-modified mortars lose critical bond strength when exposed to prolonged saturation in wet climates.

- Using improper adhesives or failing to account for temperature during the curing process results in brittle bonds prone to delamination.

Environmental Stress and Thermal Cycling

Repeated exposure to fluctuating temperatures and moisture levels exploits existing weaknesses in the rivestimento in pietra assembly. This is particularly evident in freeze-thaw climates where water trapped in the mortar pores expands by approximately 9% upon freezing. This expansion exerts massive internal pressure, shearing the interface between the natural minerals and the cementitious bed.

- Freeze-thaw cycles exert internal pressure on the mortar, causing stone spalling and displacement over several seasons.

- Wet and dry cycling causes materials to expand and contract at different rates, eventually shearing the bond at the interface.

- Thermal expansion stresses lead to ultimate veneer separation when the system lacks the durability to withstand high-dimensional changes.

Thermal Expansion Stress: Concrete vs. Natural Minerals

Bond failure often stems from the Coefficient of Thermal Expansion (CTE) mismatch between concrete-based substrates and the stone veneer, leading to interface shearing during rapid temperature cycles.

Expansion Differential Between Manufactured and Natural Stone

Concrete-based manufactured stones utilize cementitious binders and heavy pigment loads that expand and contract at significantly higher rates than natural minerals like slate or quartzite. In the volatile climate conditions of 2026, these manufactured composites struggle to remain dimensionally stable. When the veneer expands faster than the underlying substrate, it generates immense pressure on the adhesive layer, eventually snapping the bond line.

Natural stones provide a more predictable thermal profile. Because minerals like quartzite and granite formed under extreme geological pressure, their crystalline structures handle thermal loads without the internal degradation seen in porous concrete “faux” stones. This stability reduces the risk of delamination, especially in regions with high diurnal temperature swings where materials might heat to 60°C during the day and drop rapidly at night.

| Material Type | Thermal Expansion Coefficient | Primary Failure Mode |

|---|---|---|

| Manufactured (Concrete) Stone | 9.0 – 12.5 (10⁻⁶/°C) | Interface Shearing / Brittle Fracture |

| Natural Quartzite (TSS Standard) | 7.0 – 9.0 (10⁻⁶/°C) | High Dimensional Stability |

| Natural Slate (TSS Standard) | 8.0 – 10.0 (10⁻⁶/°C) | Minimal Latitudinal Movement |

Impact of Mineral Density on Thermal Stability

The aggregate and mineral density of the veneer determine its resistance to thermal shock. Dense quartzite and granite variants show exceptional stability, but they require precise installation techniques to manage their weight and inherent expansion rates. We see that lightweight natural stone panels effectively reduce total thermal mass. This reduction helps minimize the constant stress exerted on vertical wall structures during heat waves.

- Research confirms that natural minerals maintain structural integrity significantly better than concrete when surface temperatures exceed 500°C.

- Thermal hysteresis in certain marbles can cause non-adhered sections if the mortar is too rigid to accommodate crystal movement.

- High-density natural minerals resist the “cupping” or bowing effect common in thin, pigment-heavy manufactured veneers.

Mitigating Interface Failures Through Material Selection

Designers in 2026 prioritize materials that minimize movement at the critical juncture where stone meets mortar. Architects now specify natural stone veneers specifically to avoid the fading and brittleness that plague concrete products after years of UV and thermal exposure. Using 100% natural minerals ensures that the material ages uniformly with the building’s structural components.

Technical teams use high-performance polymer-modified mortars to create a bond that accommodates the subtle shifting of Pietra naturale. Strategically placed expansion joints—deeper and wider than traditional 1/4″ standards—and advanced insulation layers further reduce the thermal load. These engineering choices, combined with direct quarry sourcing for consistent mineral composition, ensure that large-scale vertical cladding systems remain intact regardless of environmental stress.

Premium Stacked Stone Panels for Professionals

Why Porosity and Moisture Retention Weaken the Bond

Substrate delamination often originates at the microscopic level, where pore defects and trapped moisture catalyze mechanical stress and chemical degradation within the adhesive interface.

Stress Concentration from Pore Defects

Internal voids within the stone or adhesive layer act as primary failure initiators by concentrating mechanical stress at specific points. These pore defects induce localized stress levels that frequently exceed the average strength of the bonding material. When an installer uses materials with irregular or large internal pores, they introduce “weak links” into the vertical assembly.

Larger pores generate disproportionately higher stress levels compared to dense, uniform structures. This concentration leads to micro-fractures in the epoxy or mortar, which eventually spider-web across the bonding surface. We manage this risk at Top Source Stone by ensuring uniform porosity in our natural stone panels, which facilitates a predictable load distribution across high-rise vertical surfaces.

| Material Factor | Bonding Impact | Failure Risk |

|---|---|---|

| Irregular Pore Defects | Localized stress concentration | Micro-fractures and delamination |

| Moisture Infiltration | Hydrolytic cleavage of polymer chains | Chemical bond softening |

| Freeze-Thaw Cycles | Internal hydraulic expansion | Mechanical separation (Prying effect) |

Hydrolytic Degradation of the Adhesive Interface

Moisture infiltration triggers chemical reactions that break down the molecular bond between the stone and the substrate. Water molecules penetrate the polymer-substrate interface, causing hydrolytic cleavage of adhesive chains. This chemical reaction essentially softens the adhesive, reducing its ability to support the weight of the stone veneer.

- Moisture accelerates bond failure by orders of magnitude compared to dry environmental conditions.

- Standard adhesives often suffer from chemical softening when exposed to consistent humidity or trapped condensation.

- Specifying high-strength, moisture-resistant epoxy resin prevents this chemical breakdown, maintaining structural integrity in wet climates.

Capillary Action and Moisture Retention in Natural Stone

The natural permeability of materials like slate and quartzite can trap water through capillary action, leading to internal pressure and bond weakening. Stone density directly affects moisture retention; higher porosity materials require advanced sealing protocols and specific installation techniques to mitigate water absorption.

Trapped moisture undergoes freeze-thaw cycles that physically pry the stone panel away from the substrate as the water expands into ice. Modern 2026 installation standards prioritize vapor-permeable barriers. These systems allow trapped moisture to escape as vapor without compromising the adhesive bond or building envelope.

Advanced Defect Detection for Structural Reliability

Modern analytical techniques allow installers and engineers to predict bonding performance by evaluating porosity before deployment. Techniques such as Micro-CT analysis identify internal air pockets and voids that traditional visual inspections miss entirely. This data allows for the selection of stones that meet the rigorous demands of multi-story cladding.

Predictive modeling helps contractors select the appropriate mortar viscosity based on the stone’s specific pore structure, ensuring maximum contact intimacy. Current 2026 protocols focus on neutralizing moisture-sensitive zones through enhanced surface preparation before applying high-performance adhesives, significantly reducing the likelihood of long-term failure.

The Importance of High-Performance Mortar for Vertical Walls

High-performance mortars serve as the critical mechanical bridge between a rigid substrate and heavy natural stone, engineered specifically to counteract gravitational pull and thermal shearing that standard masonry mixes cannot sustain.

Anti-Sag Technology for Vertical Stability

Commercial-scale vertical installations demand adhesives that hold heavy stone panels in a fixed position immediately upon contact. Modern mortars utilize thixotropic additives to achieve “instant grab,” ensuring that 6” x 24” panels remain perfectly aligned during the initial setting phase without the need for mechanical support or temporary bracing. This technology is vital when installing on smooth concrete substrates where mechanical keying is limited.

- Prevents vertical slippage of high-volume 6” x 24” panels, reducing labor costs associated with repositioning.

- Supports the precise alignment required for interlocking Z-shaped systems to ensure a seamless architectural finish.

- Reduces the reliance on temporary shimming, even when dealing with heavier profile “Rough Series” stacked stone.

Polymer-Modified Adhesion and Shear Strength

Standard Type S masonry mixes often lack the flexibility and bond strength required for 100% natural rivestimento in pietra. Advanced formulations incorporate polymer resins that create a high-strength chemical bond capable of supporting the 8-13 lbs per square foot weight typical of natural quartzite and slate. These resins allow the adhesive layer to remain flexible, accommodating subtle structural movements and vibrations that would otherwise snap a brittle, non-modified bond.

- Provides the high shear bond strength mandatory for permanent cladding on multi-story vertical facades.

- Accommodates differential movement between the stone and the structure without compromising the connection.

- Ensures long-term durability for dense, heavy materials such as Marble or Granite series.

Enhanced Water Retention for Consistent Curing

Porous substrates like brick or cement board often draw water out of standard mortar too quickly, leading to “flash drying” and a weak, powdery bond. Mortars equipped with cellulose ethers manage this moisture loss, maintaining a consistent hydration rate for the cement. This is particularly important for B2B installers working in the fluctuating climates of 2026, where maintaining a long “open time” allows for better adjustments on large-scale commercial project sites.

- Extends open time for installers, allowing for precise placement on large-scale vertical applications.

- Ensures complete chemical hydration, reaching maximum compressive strength within the specified curing window.

- Optimizes the bond on high-absorption surfaces including concrete block and fiber cement board.

Thermal Resilience and Load Management

Exterior vertical walls are subject to extreme temperature fluctuations that cause natural minerals to expand and contract at different rates than the underlying structure. High-performance mortars act as a stress-absorbing buffer, distributing the dead load of the stone cladding evenly across the entire wall surface. This prevents localized stress concentrations that typically lead to stone spalling or total veneer separation in harsh northern or high-altitude environments.

- Absorbs the kinetic energy generated by daily thermal expansion in exterior applications.

- Distributes the weight of the stone evenly, preventing failure at the bottom-most layers.

- Maintains bond integrity during aggressive freeze-thaw cycles by preventing micro-cracking within the adhesive bed.

Case Studies: Preventing Multi-Story Cladding Failures

2026 building codes now mandate non-combustible natural stone systems for high-rise envelopes to eliminate the lethal fire risks associated with traditional synthetic composites.

Transitioning to Non-Combustible Natural Stone Systems

Safety mandates in 2026 require a decisive shift from combustible composite materials to naturally fire-resistant surfaces. Architects and developers now prioritize 100% quarried natural stone panels to meet these prescriptive safety standards for high-rise residential and commercial buildings. Unlike synthetic or pigment-heavy cladding alternatives that fueled previous high-profile failures, natural stone provides inherent fire resistance without the need for additional chemical retardants.

By utilizing 100% natural minerals like those in the Top Source Stone inventory, builders effectively stop external flame spread. This material choice addresses the catastrophic risks seen in legacy systems where polymer-modified components acted as fuel during thermal events. Modern engineering focuses on the geological stability of slate, quartzite, and granite to maintain structural integrity under extreme heat.

| Safety Metric | Synthetic / Faux Veneer | Top Source Natural Stone |

|---|---|---|

| Fire Classification | Often Combustible / Smoke Toxic | Non-Combustible (Class A) |

| Fastening System | Adhesive or Plastic Anchors | Mechanical Metal Fasteners |

| Testing Standard | Performance-Based (Variable) | ANSI/FM 4880 & FM 4411 Verified |

Mechanical Fastening and Horizontal Fire Barriers

Current engineering standards emphasize mechanical fixing and story-by-story barriers to prevent vertical fire propagation in multi-story wall systems. Engineers now specify metal fasteners exclusively, as plastic anchors melt and fail during thermal events, leading to falling debris hazards. These mechanical systems ensure that natural stone panels remain secured to the building frame even under high-wind or high-heat conditions.

- Installing horizontal fire barriers between floors blocks the “chimney effect” common in cavity-based wall systems.

- Precision-cut CNC edges on Top Source Stone Z-shape panels facilitate tighter fits, reducing the air gaps that allow fire to travel.

- Mechanical clips distribute the 30-40kg/m² load of natural stone across the structural substrate, preventing localized bond failure.

Adherence to FM 4411 and ANSI Safety Standards

Modern multi-story projects require rigorous testing and third-party verification to ensure the long-term safety of the building envelope. Full-scale testing methodologies, including FM 4411, provide the data-backed approach necessary for selecting cladding in high-rise applications. Stricter enforcement of ANSI/FM 4880 standards ensures that the installed system matches the performance of tested prototypes in real-world environments.

Rigorous verification processes confirm that the material quality remains consistent across large batches. By sourcing from single quarry veins, we provide the mineral uniformity required to pass these stringent density and heat-resistance tests. This data-first approach protects both the structural integrity of the high-rise and the long-term investment of the property owner.

Conclusione

Selecting 100% natural stone minimizes the risks of thermal expansion and moisture-related bond failure that often plague synthetic alternatives. These technical considerations ensure the long-term safety of vertical cladding and reduce maintenance costs for large-scale structural projects. High-performance materials protect both the building facade and the professional reputation of the installation team.

Evaluate the stone specifications on your upcoming projects to ensure they provide the durability required for high-exposure environments. You can contact Top Source Stone to request technical data sheets or to discuss direct-quarry sourcing for your inventory needs.

Domande frequenti

Why is my stone veneer falling off?

Stone veneer failure is typically caused by moisture entrapment behind the stone, which weakens the mortar bond and leads to rot or mold. Common installation errors include insufficient mortar contact (less than 100% coverage), the absence of a proper drainage plane, and undersized expansion joints that cannot accommodate structural movement. Additionally, freeze-thaw cycles and the use of low-quality polymer-modified mortars that lose strength when saturated often lead to ultimate separation.

How to prevent stone veneer failure?

Prevention requires a rigorous moisture management strategy, including the installation of a high-quality weather-resistant barrier (WRB) and a functional drainage plane to prevent water from sitting behind the veneer. Ensure installers utilize full-depth mortar bedding to achieve 100% contact intimacy and detail all joints with backer rods and appropriate sealants. Properly sized expansion joints and flexible anchorage systems should also be used to allow for differential movement without stressing the bond.

Does heat make stone veneer detach?

Yes, thermal cycling is a significant factor in veneer detachment. As the stone and the underlying substrate expand and contract at different rates due to temperature fluctuations, it creates shear stress on the mortar bond. If the system lacks adequate expansion joints or flexible anchorage to absorb this movement, the resulting expansion stress can cause the stone to spall, the mortar to displace, and the veneer to eventually delaminate from the wall.

Is real stone safer for tall buildings?

Real stone can be safer for high-rise applications when utilized as part of a mechanically anchored system. Unlike thin-set veneers that rely entirely on chemical adhesion, natural stone panels are typically secured with stainless steel pins or clips. This mechanical connection is superior for managing the high wind loads and significant structural movement common in tall buildings, though it must be properly detailed to avoid issues like edge-set delamination or rigid-connection failure.

Best adhesive for heavy stone veneer?

The industry standard for heavy stone veneer is a high-performance Type S masonry mortar, often enhanced with polymer additives to improve flexural strength and water resistance. For maximum security, heavy veneers should always be installed using a “full-depth” bedding technique to ensure 100% surface contact. In high-load or exterior applications, this chemical bond should be supplemented with mechanical masonry ties to ensure long-term structural integrity.