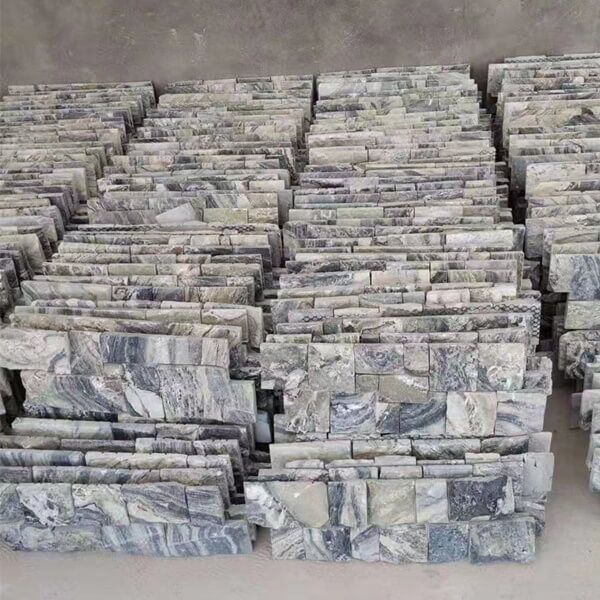

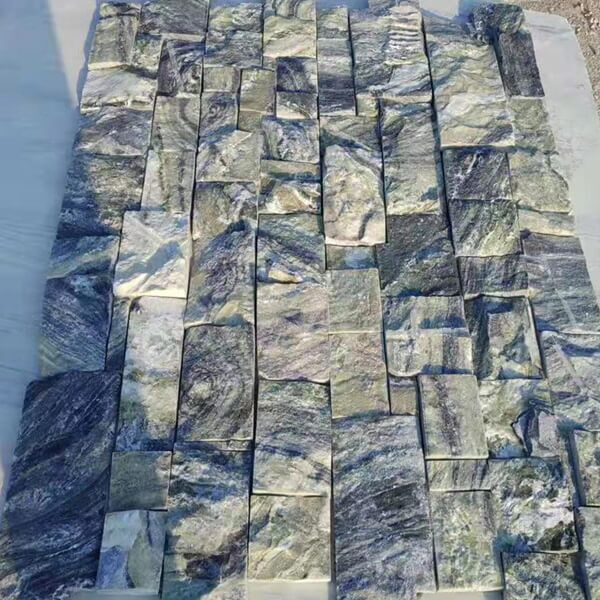

Our Cheap Cement Back Marble Stone Ledger Panel Wall Cladding delivers authentic natural marble beauty without the cost barrier of traditional stone installation. The cement backing system provides structural stability while maintaining the visual elegance that architects, contractors, and building developers expect. Each panel features genuine marble with a finished marble surface, engineered for efficient installation and long-term durability in both interior and exterior applications.

The cement bond creates a reliable connection between the natural stone veneer and your wall surface, eliminating the complexity of traditional stone-by-stone placement. This pre-assembled solution lets your teams work faster and produce results that look custom-designed, not mass-produced.

Key Product Specifications:

- Material: Natural Marble with Cement Backing

- Panel Format: Ledger/Stacked Stone Configuration

- Standard Dimensions: 20 × 60 cm (can be customized)

- Thickness: 3–4 cm

- 重さ: Approximately 80 kg/m²

- Surface Options: Split, Machine Cut, or Custom Finishes

- Color Range: Available in Grey, Beige, Black, Rusty, Red, Green, and other stone tones

Application Showcase

These marble ledger panels transform spaces across multiple markets:

Residential ApplicationsInterior accent walls, fireplace surrounds, and entryways gain dramatic visual impact. Bathroom walls and spa areas benefit from the moisture-resistant cement backing. Exterior façades gain depth and texture without requiring specialized masonry skills.

Commercial & Hospitality

Hotel lobbies, office building entrances, and restaurant feature walls establish premium brand presence. Shopping centers use ledger panels for high-traffic focal points that withstand constant foot traffic. Conference centers and corporate offices employ these panels to create sophisticated, modern interiors.

Industrial & Institutional

Building facades for office complexes and institutional structures gain architectural distinction. Pool decks and wet areas utilize the superior moisture resistance of the cement backing. Healthcare facilities incorporate stone cladding for elegant, easy-to-maintain wall systems.

Outdoor Installations

Garden walls, landscape features, and exterior home accents perform reliably in varying weather conditions. Building exteriors gain protective cladding that resists UV exposure, temperature cycling, and moisture penetration.

Package Method

Standard Shipping Configuration

Your panels arrive securely packaged to prevent damage during transit:

- Carton Packing: 4 panels per carton for single-panel orders or smaller projects

- Wooden Crate System: 30 cartons per fumigated wooden crate, protecting panels during long-distance transport

- Container Capacity: 25 crates per 20-foot shipping container (approximately 1.1 tons per crate)

- Crate Dimensions: 116 × 70 × 115 mm (each crate)

Moisture Protection

Fumigated or fumigant-free wooden crates ensure your panels arrive dry and undamaged. The packaging system allows efficient stacking and handling by standard forklift equipment at ports and distribution centers.

Handling Protocol

Panels should be stored in a dry environment before installation. Standard pallet configurations integrate with existing warehouse management systems. Material handlers can quickly assess inventory and prepare panels for job sites.

Minimum Order Requirements

- 100 m² per order (typical for regional projects)

- 1 × 20-foot container (standard for full shipment)

Bulk purchasing offers cost efficiency for larger developments, hotel chains, or multi-property projects.

The Core B2B Value Proposition

- Cost-Effective Marble Installation: Traditional marble cladding requires individual stone placement, grout work, and specialized installation crews. Your Cheap Cement Back panels eliminate this complexity. Contractors complete installations 40–60% faster, directly reducing labor costs and project timelines.

- Fast Installation Timeline: Standard mortar adhesion bonds panels to walls in one pass. No individual piece fitting. No complex cutting sequences for most installations. Teams move through square footage at production rates comparable to drywall finishing, not specialized stonework.

- Predictable Project Budgeting: Bulk pricing and standardized panel dimensions remove quote surprises. Contractors provide clients with firm numbers upfront. Shipping costs and timelines remain consistent across multiple projects. Minimal waste—panels fit predictably into standard wall dimensions.

- Quality Consistency: Natural marble surface ensures authentic stone appearance. Each color selection maintains uniform character. Reference samples provided with every shipment confirm visual consistency with previous orders.

- Superior Moisture Performance: The cement backing provides inherent moisture resistance superior to traditional drywall substrate systems. Bathroom installations, pool surrounds, and outdoor walls gain durability typically reserved for ceramic tile or expensive stone systems.

- Flexible Customization: Surface finish options (split, machine-cut, honed) allow specification flexibility. Color range addresses both traditional and contemporary design preferences. Panel dimensions can be adjusted for specific project requirements with sufficient order volume.

- Global Supply Reliability: Direct sourcing from major production regions. Multiple shipping routes ensure availability. Experienced export logistics minimize delivery disruptions.

Technical & Logistics Specifications

Material Composition & Performance

The marble veneer combines with a cement-based backing system that delivers structural support and moisture resistance. This engineering approach maintains the authentic aesthetics of natural stone while adding functionality modern construction requires.

Durability Characteristics

- Moisture Resistance: Cement backing prevents water absorption that degrades traditional drywall substrates

- Mold & Mildew Resistance: Dense cement composition lacks organic material that mold requires—critical for bathrooms and outdoor applications

- Freeze-Thaw Performance: Suitable for regions experiencing temperature cycling

- UV Stability: Natural marble resists color fading from extended sun exposure

- Acid Resistance: Protects against common building material interactions

Structural Properties

- Weight per Square Meter: 80 kg (important for load calculations on walls)

- Impact Resistance: Cement backing absorbs stress that would crack thin marble

- Compression Strength: Cement system supports multiple panel layers without substrate failure

- Bond Strength: Thinset mortar or stone-specific adhesive creates permanent mechanical connection

Logistics & Shipping Details

| Specification | Details |

| Port of Loading | Tianjin Port, China |

| Typical Transit Time | 15 days after deposit payment |

| Export Markets | Europe, Australia, Middle East, Americas |

| Container Type | 20-foot standard shipping container |

| Total Container Weight | Approximately 27.5 tons (full load) |

| Pallet Configuration | Standard 40 × 48 inch compatibility |

| Customs Classification | Natural stone cladding (HS Code 6802.23) |

Payment & Order Terms

- Payment Method: T/T (wire transfer), Western Union, PayPal accepted

- Deposit: 30% required to secure production slot

- Balance: 70% due against bill of lading copy

- Lead Time: 15 days production after deposit received

Manufacturing & 品質管理

生産工程

Our manufacturing facilities employ established techniques refined over decades of natural stone production. Real marble is sourced from quarries known for consistent color and quality. Each block undergoes visual inspection before processing.

The splitting or cutting process creates uniform panel dimensions. Marble surfaces are cleaned to remove any quarry dust or processing residue. The cement backing is applied in controlled-thickness applications, ensuring consistent coverage and curing.

Quality assurance teams inspect finished panels against reference samples. Color variation typical of natural stone is documented and accepted—this natural characteristic distinguishes genuine marble from artificial alternatives.

Verified Production Standards

Manufacturing facilities maintain ISO certifications and undergo third-party audits. Export compliance documentation accompanies every shipment. Production records track material sourcing and processing dates, providing traceability for large commercial projects requiring documentation.

Reference Samples & Consistency

Every production run includes reference samples that establish the visual baseline for that order. Your team receives samples before bulk shipment, allowing design approval before installation begins. This quality gate prevents color or finish surprises on job sites.

| 製品サイズ | 55X20cm | 61×15.2cm | 55X20cm |

| 個/カートン | 4個 | 4個 | 4個 |

| カートン/パレット | 48カートン | 48カートン | 36カートン |

| 平方メートル/パレット | 21.12平方メートル | 17.80sqm | 15.84平方メートル |

| 平方メートル/20FCL | 337.92平方メートル | 338.20sqm | 332.64平方メートル |

| 重量/平方メートル | 80kg | 80kg | 80kg |

| 重量/パレット | 1650kg | 1400kg | 1270kg |

| パレット・コンテナ | 16パレット | 19パレット | 21パレット |

| 20FCL | 27トン | 27トン | 26.6トン |

Installation Benefits for Contractors

- Speed Translates to Profitability: Standard installations proceed at rates comparable to large-format tile work—roughly 30–50 square feet per labor hour depending on surface prep complexity. A 500-square-foot feature wall takes one experienced installer 10–15 working hours. Traditional marble or stone-by-stone cladding requires double or triple this time.

- Streamlined Crew Skills: Your team doesn’t need specialized marble masons. Standard tile setters, drywall finishers, or general contractors handle installation using familiar tools (notched trowel, level, rubber mallet). This flexibility expands the contractor pool capable of bidding projects, improving competition and pricing for end clients.

- Reduced Material Waste: Standardized panel sizing cuts waste to minimal levels. Unlike traditional stone work where custom cutting creates substantial offal, ledger panels use almost entirely installed material. This reduces job-site cleanup time and disposal costs.

- Surface Preparation Simplification: Clean, flat surfaces accept panels—drywall, concrete block, or cement board work equally well. No need for specialty substrates. If a wall isn’t perfectly smooth, standard drywall taping compounds or thin-set mortar level the surface. Equipment requirements remain basic: trowels, levels, and mallets.

- Quality Control at Installation: Panels arrive uniform and consistent. Visual defects are rare because manufacturing processes screen for quality. Installation defects become contractor-controllable factors. Proper mortar coverage and level panel placement produce predictable results.

- Warranty & 耐久性: Properly installed panels last 20+ years. Cement backing resists moisture deterioration that compromises traditional drywall substrates. The investment your clients make performs reliably, supporting contractor reputation and reducing callback issues.

- Project Flexibility: Panels adapt to various architectural styles. Contemporary designs showcase the clean ledger lines. Traditional projects benefit from split finishes mimicking natural stacked stone. Color selection addresses neutral and bold design choices without special orders.