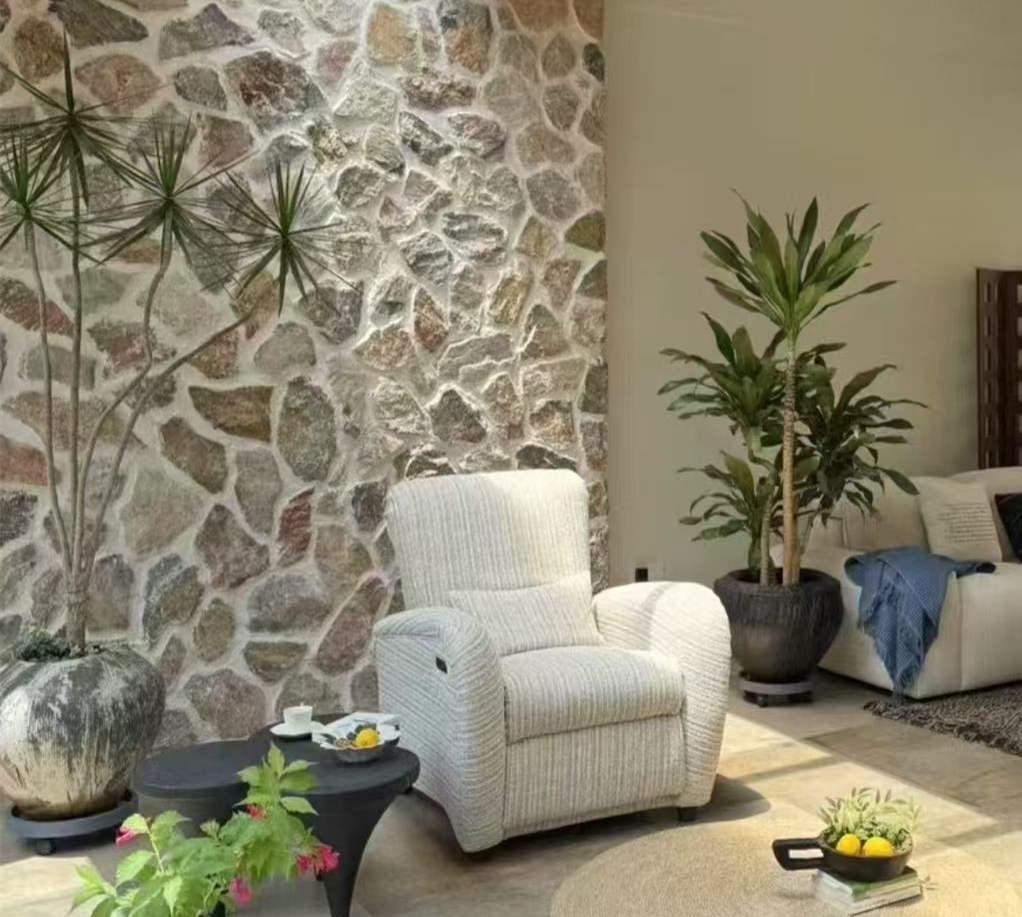

Thin Stone Veneer Guide: Best Stone Types for Durability & Low Water Absorption

Choosing the right stone species is critical for thin veneer durability and moisture resistance. This guide compares slate, quartzite, limestone, and sandstone based on water absorption, structural stability, and exterior performance. A technical reference for architects, builders, and wholesale distributors.