An outdoor fireplace install requires more than aesthetic planning; it demands a rigorous engineering approach to prevent structural failure and costly liability issues. When exterior stone fails, the cause usually traces back to thermal expansion or moisture penetration that weakens the bond between the stone and the substrate. Contractors face significant profit loss and reputational damage when they must perform remedial work due to poor material selection or neglected waterproofing protocols. Ignoring the physics of freeze-thaw cycles leads to stone delamination, creating hazardous conditions and voiding project warranties.

This guide establishes the technical requirements for building durable stone surrounds, focusing on substrate preparation and specific adhesive performance for extreme temperatures. We address the methods for managing water drainage behind the stone and selecting materials that resist UV degradation in direct sunlight. These standards serve as a technical roadmap for ensuring every exterior fireplace remains structurally sound and visually consistent despite constant exposure to the elements.

Why Outdoor Fireplaces Demand Different Stone and Adhesives

Outdoor fireplace surrounds fail when installers apply interior-grade materials to high-thermal-stress environments; longevity requires 100% natural stone panels and specialized epoxy resins capable of managing rapid heat expansion.

Thermal Stability of Natural Stone Over Synthetic Alternatives

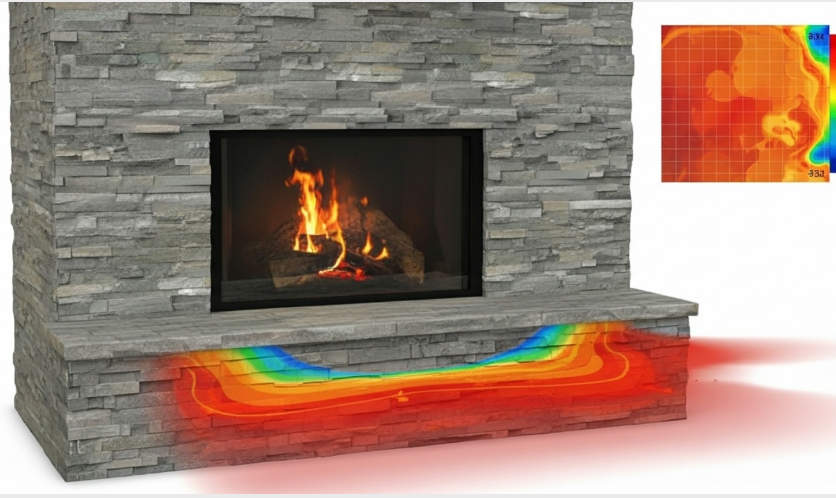

Natural stone panels, particularly those sourced from high-density quartzite or slate veins, offer non-combustible properties essential for fire-adjacent zones. Synthetic or “cultured” stones rely on concrete composites and chemical pigments that often micro-crack or discolor when subjected to consistent high-heat cycles. By 2026 market standards, professional masonry specifications favor real quarried stone because it functions as an efficient thermal mass. This allows the fireplace to radiate heat effectively without the risk of off-gassing or structural degradation common in human-made alternatives.

| Performance Metric | Top Source Natural Stone | Synthetic/Faux Stone |

|---|---|---|

| Thermal Tolerance | Up to 1090°C (Natural Cleft) | Cracks/Degrades > 150°C |

| Color Composition | Through-Body Mineral Hue | Surface-Applied Pigments |

| Moisture Absorption | ASTM Low Porosity (< 0.5%) | High Absorption (2% – 8%) |

Our rough series and flat series panels utilize 100% natural minerals, ensuring the structural integrity of the hearth. Thick-cut natuursteen provides a dense mass that withstands direct flame proximity without melting or losing pigment, a critical requirement for high-end residential and commercial outdoor lounge designs.

Epoxy Resin Adhesives for Extreme Temperature Cycling

Standard cement-based mortars lack the elastic modulus required to handle the differential expansion between Stenen bekleding and the underlying substrate. We specify high-strength epoxy resin adhesives formulated to maintain a permanent bond during rapid thermal fluctuations. These adhesive systems remain flexible enough to accommodate the physical expansion of the stone when heated, preventing the brittle failure typical of traditional bonds.

- Thermal Expansion Management: The bond absorbs the stress of stone movement between freezing nights and high-heat fires.

- Delamination Prevention: Specialized resins ensure stone panels remain fused to cement board or masonry even in wet, high-heat zones.

- Freeze-Thaw Durability: Moisture-resistant adhesives prevent water from pooling behind the stone and causing frost heaving.

UV Resistance and Color Permanence in Exposed Environments

Outdoor fireplaces face brutal exposure to direct sunlight, which can bleach inferior materials in a single season. Natural stone panels like our Glacier White or Carbon Black series feature through-body color that remains vivid for decades. Since the color is an inherent mineral property rather than a surface dye, the stone weathers naturally while maintaining its architectural value. Adhesives used in these 2026 systems are shielded by the stone panels but are also selected for their resistance to yellowing and degradation under extreme exterior conditions.

Using CNC diamond-blade precision during manufacturing ensures that each Z-shape or S-shape panel fits tightly, further protecting the substrate and adhesive from UV rays. This seamless interlocking technology eliminates visible “stepped” gaps and creates a unified surface that resists environmental wear better than hand-cut or synthetic alternatives.

Managing Freeze-Thaw Cycles in Exterior Stone Surrounds

Preventing stone delamination in cold climates requires a dual-strategy of selecting ultra-low porosity materials and engineering a drainage path that allows incidental moisture to exit the substrate before it freezes.

Selecting Low-Porosity Natural Stone for Cold Climates

Dense materials serve as the primary defense against frost damage. Porous stones like domestic sandstone or travertine absorb significant water volume, which then expands by roughly 9% when it turns to ice. This internal pressure causes spalling and structural cracking. We prioritize high-density quartzite and slate panels for 2026 exterior projects because their tight crystalline structure resists liquid infiltration.

| Performance Metric | Generic Sedimentary Stone | Top Source Quartzite/Slate |

|---|---|---|

| Absorption Rate (ASTM C67) | 2.0% – 8.0% (High Risk) | < 0.5% (Freeze-Thaw Resistant) |

| Adhesive Compatibility | Standard Type S Mortar | High-Strength Epoxy Resin Bond |

| UV & Thermal Stability | Prone to fading and fatigue | Inherent stability; no fading |

Implementing Substrate Waterproofing and Drainage Systems

Stone panels do not function as a waterproof barrier. Moisture inevitably finds a path behind the veneer, so the underlying structure needs dedicated protection. A rainscreen approach uses drainage mats with vertical channels to direct water downward toward a weep screed at the base. This setup ensures that water escapes the wall assembly instead of saturating the stone bond coat or rotting the cement board.

- Install a high-grade weather-resistant barrier (WRB) in a shingle-style overlap pattern to shed water.

- Apply flashing at all transitions and headers to redirect moisture away from the chimney core.

- Design the installation site with a slight outward slope to keep water from pooling at the base of the stone surround.

Managing Thermal Expansion with Movement Joints

Natural stone and concrete substrates expand and contract at different rates during rapid temperature shifts. Rigid installations without flexibility often suffer from delamination or shear failure. We incorporate vertical and horizontal movement joints every 8 to 12 feet to absorb these physical shifts. Using polymer-modified thin-set mortars specifically engineered for exterior use provides the necessary flexibility for the stone to move slightly without breaking the bond.

Applying Breathable Sealants for Long-Term Protection

Proper sealing prevents liquid water entry but must allow the stone to release internal vapor. Silane-siloxane penetrating sealants create a hydrophobic barrier while remaining breathable. This prevents the “trapped vapor” effect that causes freeze-thaw damage from the inside out. Annual inspections remain necessary to identify hairline cracks in joints where water might infiltrate, especially in high-exposure 2026 climate zones.

- Apply penetrating sealants that block liquid water but allow water vapor to escape.

- Clean surfaces with pH-neutral solutions to avoid stripping the protective sealant layer.

- Perform a water-bead test every 12 months to verify the integrity of the barrier.

Scale Your Projects With Premium Natural Stone

Waterproofing the Chimney Structure Before Applying Stone

Moisture infiltration behind stone veneer causes over 90% of structural bond failures in outdoor fireplaces; a multi-layered drainage system is the only way to ensure long-term adhesion.

Effective waterproofing begins with meticulous substrate preparation. We use stiff wire brushes to strip away loose debris, flaking mortar, and dirt that would otherwise compromise the bond between the waterproofing membrane and the chimney wall. The surface must remain completely dry before any liquid barriers or membranes are applied. Inspecting mortar joints at this stage is mandatory, especially for older brick chimneys, as these joints act as the primary entry points for water that can lead to delamination during freeze-thaw cycles.

| Waterproofing Layer | Technical Specification | Structural Function |

|---|---|---|

| Weather-Resistant Barrier (WRB) | 2-inch minimum shingle-style overlap | Directs bulk water downward and away from the substrate. |

| Drainage Mat | Vertical channel configuration | Prevents hydrostatic pressure and facilitates air circulation. |

| Fasteners | Galvanized staples (6-8 inch spacing) | Secures barriers against wind-loading and thermal expansion. |

Weather-Resistant Barrier (WRB) Implementation

Install the weather-resistant barrier using a shingle-style overlap pattern to create a shed-like effect for moisture. Start at the base of the chimney and work upward, ensuring each subsequent layer overlaps the one below by at least 2 inches. This configuration forces water to stay on the exterior of the barrier rather than seeping into seams. We secure these layers with galvanized staples every 6 to 8 inches to maintain a tight, flush fit against the chimney wall, preventing the “pillowing” effect that can interfere with stone panel leveling.

Drainage Mats and Rainscreen System Integration

In climates prone to heavy rain or snow, a rainscreen system is essential. This involves:

- Applying drainage mats with vertical channels to provide a clear path for water to exit the system quickly.

- Using mortar-blocking fabric to keep adhesive from clogging the drainage paths during the installation of stacked stone panels.

- Installing weep screeds at the base of the chimney to allow trapped moisture to escape and encourage air drying.

Material-Specific Waterproofing Requirements

Different chimney substrates react differently to moisture. Concrete blocks are highly porous and often require multiple passes of solvent-based sealers to reach full saturation before the stone veneer is applied. Brick chimneys demand extra focus on the mortar joints, where most leaks originate. For existing stone chimneys, evaluate the silica content of the stone before selecting a chemical waterproofing agent, as certain sealants react poorly with specific mineral compositions, potentially causing surface staining or bond failure.

Choosing Stone Colors That Won’t Fade in Direct Sunlight

Natural stone’s inherent mineral composition provides permanent UV resistance that chemical pigments in manufactured concrete alternatives cannot match in high-exposure outdoor environments.

Selecting materials for an outdoor fireplace requires a focus on long-term color stability. Unlike manufactured stone, which relies on surface-level iron oxide pigments that degrade under constant ultraviolet bombardment, natural ledger stone panels consist of 100% quarried material. This geological advantage means the color runs through the entire body of the stone, ensuring the aesthetic remains consistent even if the surface experiences minor wear over decades of use.

Natural Stone Advantage Over Pigmented Concrete

Professional installers and B2B suppliers in 2026 prioritize real stone for exterior projects to eliminate the risk of “bleaching”—a common failure in artificial composites where the sun’s rays break down the synthetic bonding agents and dyes. Natural stones like slate and quartzite contain stable minerals that have already withstood millions of years of environmental exposure before reaching the quarry.

- Natural stones resist UV degradation naturally, maintaining their original hue without the need for periodic staining or color restoration.

- Real stone surfaces retain their resale value and structural appeal, avoiding the “plastic” look that develops when manufactured stone begins to fade unevenly.

- Sourcing from the same quarry vein ensures batch consistency, which is critical for large-scale outdoor fireplace surrounds that catch direct sunlight from multiple angles.

UV-Stable Mineral Properties of Quartzite and Marble

Different mineral structures react differently to solar heat. Quartzite series panels are particularly effective for high-sun areas because their crystalline structure reflects a significant portion of the UV spectrum. This reflection protects the internal integrity of the stone, preventing it from becoming brittle or chalky. Marble series options, such as Royal White, offer an elegant aesthetic that resists the yellowing often seen in resin-heavy synthetic materials.

- Quartzite panels reflect sunlight, keeping the stone’s temperature lower and maintaining structural integrity during intense heat waves.

- Dense mineral compositions in marble prevent yellowing, ensuring white and light gray tones stay vibrant and crisp.

- The split-face finish of natural stone creates micro-shadows that mask minor environmental wear, unlike flat, painted surfaces.

Heat Reflectivity in Light-Colored Exterior Finishes

Thermal performance is just as important as visual stability. Lighter color palettes—including white, cream, and light gray—improve the fireplace’s longevity by reflecting solar energy rather than absorbing it. Designers frequently specify Arctic White or light gray slate for 2026 projects to create high-impact focal points that remain cool to the touch and visually bright even in harsh, direct lighting.

- Light-colored stones like Glacier White reduce thermal expansion and contraction, which protects the adhesive bond behind the stone.

- The Flat Series in lighter tones minimizes perceived color shifts by reducing deep shadows where dust and airborne pollutants typically accumulate.

- Light gray and cream stones complement modern outdoor living spaces while providing superior solar reflectance compared to dark charcoals or blacks.

Preserving Surface Vibrancy Through Proper Sealing

While the internal color of the stone is permanent, the surface requires protection from environmental dulling caused by smog, pollen, and hard water. Applying a high-quality, pH-neutral sealer prevents UV rays from reacting with surface contaminants. This doesn’t change the stone’s inherent resistance but keeps the “visual clarity” high, ensuring the natural highlights of the quartzite or slate remain sharp.

- Breathable sealers allow moisture to escape the stone while blocking external liquids that can carry fading-inducing minerals.

- Regular maintenance with soft brushes and water removes the “dust film” that often makes stone appear faded when it is actually just dirty.

- Using UV-rated sealants provides an extra sacrificial layer that absorbs solar energy, protecting the stone’s natural matte or “wet look” finish.

Cleaning Moss and Algae Off Outdoor Fireplace Stone

Outdoor fireplace stone requires a balance of mechanical removal and pH-neutral chemistry to eliminate organic growth without triggering thermal shock or surface etching.

Manual Scrubbing with Soft Brushes

Mechanical removal serves as the first line of defense against thick moss buildup. Start with stiff nylon or natural fiber brushes because they dislodge organic matter without scouring the stone’s natural cleft or split-face texture. This step is most effective when performed on dry stone, as it prevents the spread of wet spores into the deep crevices of the ledger panels.

- Use stiff nylon or natural fiber brushes to dislodge thick moss and dried algae without scratching the stone surface.

- Avoid wire brushes, as metal bristles can leave behind fragments that rust and cause permanent staining on quartzite or marble.

- Work on dry stone first to remove loose material before applying any liquid cleaners.

pH-Neutral Cleaning Solutions

Chemical selection often determines the longevity of the installation. Since many fireplace surrounds use calcium-based stones or sensitive silicates, acidic cleaners—including common household vinegar—cause immediate surface etching. A professional-grade, pH-neutral stone soap mixed with warm water breaks down the biofilm without compromising the structural integrity of the slate or quartzite.

- Apply a mixture of warm water and pH-neutral stone soap to break down remaining organic spores.

- Avoid acidic cleaners like vinegar or lemon juice, which react poorly with the calcium carbonate in marble and can dull the finish of slate.

- Rinse the stone thoroughly with clean water to ensure no soapy residue remains to attract new dirt.

Low-Pressure Rinsing Techniques

High-pressure washing is typically too aggressive for interlocking Z-shape ledger panels. Keeping equipment settings below 1,500 PSI protects the high-strength epoxy bonds and prevents water from being forced behind the stone. If moisture penetrates the substrate, it can lead to delamination during the next high-heat fire cycle. Always direct the spray at an angle rather than head-on into the joints to flush out sediment safely.

- Keep pressure washer settings below 1,500 PSI to prevent dislodging the high-strength epoxy bond holding the ledger panels.

- Maintain a safe distance from the stone surface to avoid forcing water behind the panels, which can compromise the moisture barrier.

- Focus the spray at an angle rather than directly into the interlocking Z-joints.

Preventive Sealant Application in 2026

Long-term protection depends on moisture management. Once the stone has dried for a minimum of 48 hours following a deep clean, apply a breathable, penetrating sealer. For outdoor fireplaces, select a sealant specifically rated for high-heat environments to ensure the chemical bond remains stable near the firebox. Modern standards in 2026 emphasize these vapor-permeable barriers because they allow internal moisture to escape while blocking the liquid water that fuels algae growth.

- Apply a high-quality, breathable penetrating sealer once the stone has dried for at least 48 hours following a deep clean.

- Select sealants specifically rated for high-heat environments to ensure the protection remains effective near the firebox.

- Reassess the stone surface in 2026 to determine if a fresh coat is needed based on local humidity and shade levels.

Conclusion

Landscape architects rely on engineering-grade materials to ensure outdoor fireplaces survive extreme weather without structural or aesthetic degradation. Sourcing 100% natural stone directly from the quarry provides the UV stability and moisture resistance needed for long-term exterior performance. These technical considerations prevent common issues like stone delamination and color fading over time.

You can view our technical manuals or request a professional sample kit to verify the precision of our interlocking panels for your next project. Our specialists are available to discuss batch-specific availability for large-scale landscape designs.

Veelgestelde vragen

What is the best stone for an outdoor fireplace?

Granite, limestone, and slate are considered the premium choices for outdoor fireplaces due to their exceptional heat-retention properties and weather durability. Granite, in particular, is highly recommended for its resistance to thermal shock and environmental wear, while locally-sourced natuursteen provides a sustainable, high-performance alternative to chemically-processed materials.

Can exterior stacked stone handle heavy rain and snow?

Yes, exterior stacked stone is specifically engineered to withstand extreme environmental stress, including heavy precipitation and freeze-thaw cycles. When installed with specialized adhesives and reinforced concrete foundations, these stone systems maintain structural integrity against moisture penetration and the physical weight of snow accumulation.

Do I need to seal an outdoor stone fireplace more often?

Outdoor stone fireplaces typically require more frequent sealing—usually every 12 to 24 months—compared to indoor units. This is because the stone is constantly exposed to UV radiation, acid rain, and soot, which can break down protective barriers faster. Regular sealing prevents water absorption and protects the stone from staining caused by environmental debris.

How to prevent stone from falling off an outdoor fireplace?

Prevention starts with a reinforced concrete foundation to prevent shifting and the use of specialized, high-bond adhesives. You must ensure the substrate is clean and use a “back-buttering” technique where adhesive is applied to both the fireplace wall and the back of the stone to ensure 100% surface contact, mitigating the risk of delamination during thermal expansion.

Best adhesive for extreme outdoor temperatures?

The industry standard for extreme temperatures is a high-performance, polymer-modified thin-set mortar. These specialized adhesives are formulated to be flexible, allowing the stone to expand and contract during rapid temperature changes without cracking or losing its bond. Always select a professional-grade adhesive rated specifically for exterior masonry and thermal stress.