Project managers rarely hit Labor ROI targets when they focus on stone unit costs instead of the 5x installation multiplier that consumes 75% of renovation budgets. Traditional hand-stacked masonry limits coverage to 3 square feet per hour, which drives up hourly billables and erodes profit margins on large stone projects.

We analyze how 6×24 interlocking Z-Shape panels and matching L-Corners increase output to 15 square feet per hour. Utilizing CNC diamond-blade precision and same-batch quarry consistency allows general crews to achieve professional finishes while reducing on-site non-productive time by 40%.

The True Cost of Installation: Balancing Labor vs. Material Spend

Labor represents 65-75% of renovation costs. Stone installation typically multiplies material expenses by five, making engineered panels essential for controlling budgets and reducing specialized masonry hours.

Analyzing the Material-to-Labor Multiplier in Masonry

Calculating a project based on the stone’s square-foot price is a common mistake for inexperienced importers. In the field, the material cost is only a small fraction of the total invoice. For naturstein, labor and project management typically scale at a 5x multiplier relative to the stone’s purchase price.

Contractors must calculate the “burdened rate” to understand the real impact on the bottom line. This rate includes the base wage plus an additional 30-40% for workers’ compensation, payroll taxes, and specialized masonry insurance. When these costs are high, the perceived savings of buying cheap, loose stone vanish during the hand-sorting and dry-stacking process.

- Labor Intensity: Installation accounts for 65-75% of total renovation spend in residential and commercial stone projects.

- The 5x Multiplier: Every $1,000 in visible stone material often requires $4,000 to $5,000 in labor and management to install correctly.

- Efficiency Loss: Traditional hand-stacked loose stone covers only 2-3 square feet per hour, driving up hourly billables.

Reducing Labor Burdens with Precision-Engineered Z-Panels

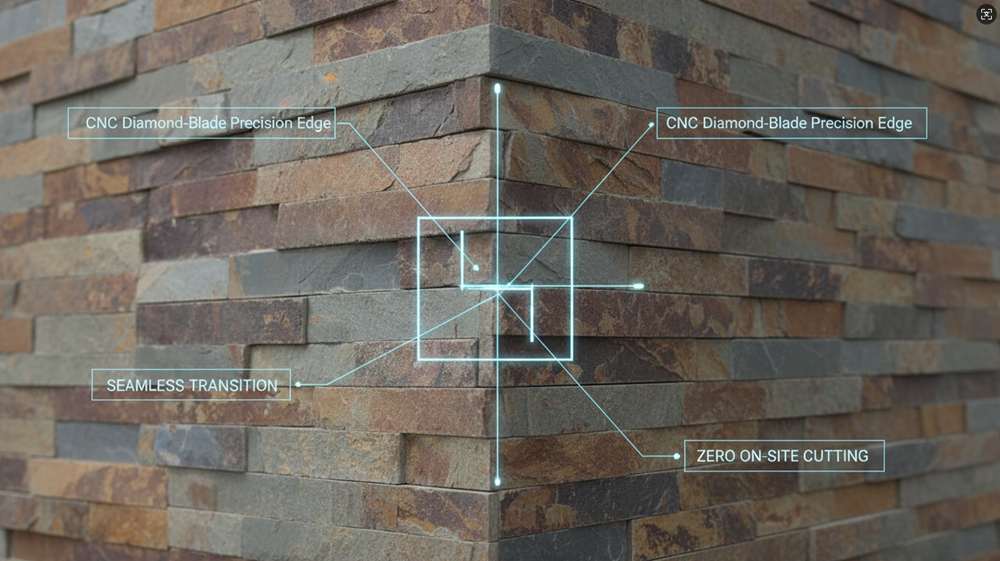

Top Source Stone addresses the labor crisis by shifting the workload from the field to the factory. We use CNC diamond-blade precision on our Z-Shape and S-Shape interlocking models. This ensures a tight “male-female” connection that accelerates installation speeds by up to 10x compared to hand-stacking raw stone.

The modular 6×24 design allows general crews or tile installers to achieve a professional architectural finish without the need for high-priced master masons. By using our pre-fabricated matching L-Corners, installers eliminate on-site miter cutting, which reduces waste and cuts hours off the project timeline.

- Installation Speed: Z-panel systems cover 10-15 square feet per hour, a 200% increase over traditional methods.

- Corner Efficiency: Pre-fabricated 90-degree L-Corners synchronize color and texture without manual field adjustments.

- Technical Precision: CNC edges create a seamless interlock that camouflages vertical joints and hides the installation substrate.

- Standard Specs: Panels are 6″ x 24″ (150x600mm) with a thickness of 1cm to 3.5cm, optimized for consistent pallet loading and handling.

How Many SQM Can a Professional Crew Install Per Day?

A two-person crew installs 25-35 square meters daily using modular panels, outperforming loose stone masonry by nearly 600% through precision-engineered interlocking features and pre-fabricated corners.

Daily Output Benchmarks for Modular Stone Panels

Labor productivity in 2026 hinges on the shift from manual masonry to modular systems. A two-person team—typically one lead setter and one helper—maximizes the workflow by separating material staging from active wall mounting. This division of labor keeps the setter focused on placement while the helper manages cuts and adhesive prep.

- Standardized Units: Every 6″ x 24″ panel replaces dozens of individual loose stones, drastically cutting the number of manual placements required to cover a square meter.

- Weight Factors: Flat Series panels weighing 30-40kg/m² allow for faster handling and positioning. Rough Series panels reach 55kg/m², which naturally slows the pace due to increased physical fatigue.

- Site Complexity: Windows, electrical outlets, and wall height impact performance. Crews should adjust daily output estimates by 15-20% when dealing with high-detail architectural features.

Labor Savings from Z-Shape Precision and L-Corners

Engineering at the factory level directly reduces on-site hours. CNC diamond-blade edges create a precise male-female interlock, so installers spend zero time on manual joint adjustments or hiding substrate gaps. This precision ensures the stones fit together without the “trial and error” common in lower-grade imports.

- Automated Joint Camouflage: Z-shape and S-shape panels hide vertical joints automatically. Crews maintain a continuous pace because they don’t have to stop and check for visible “stepped” gaps.

- Pre-fabricated Transitions: Matching 90-degree L-corners remove the need for on-site miter cutting. This feature typically saves 90 to 120 minutes of specialized labor per corner transition.

- Same-Batch Consistency: Toppkildestein sources from the same quarry vein per order. This minimizes the time crews spend “dry-running” or sorting through crates to find color harmony before the first panel hits the wall.

By utilizing these engineered features, contractors can bid more competitively on large-scale projects while maintaining higher margins through reduced man-hours.

Premium Stacked Stone for Architectural Success

Tooling vs. Manpower: Which Investment Offers Higher Returns?

High-precision tooling delivers higher returns by slashing production cycles 30-50% and eliminating on-site manual sorting, significantly reducing the labor-intensive 5x-6x material cost multiplier typical in stone projects.

| Metric | High-Precision Tooling (Toppkildestein) | Traditional Manual Methods |

|---|---|---|

| Production Cycle | 30–50% Faster (Aluminum Tooling) | Baseline Speed (Steel/Standard) |

| On-Site Labor Needs | Low-skill interlocking assembly | Highly skilled mason required |

| Field Adjustments | Minimal (CNC-cut precision) | High (Manual grinding & miter cuts) |

| Joint Camouflage | Automatic (Male-Female Interlock) | Manual pointing and grout matching |

Efficiency Gains through Production Cycle Optimization

Advanced aluminum tooling transforms the economics of stone manufacturing. While traditional steel methods are the industry baseline, aluminum tools reduce production cycle times by up to 50% for medium and large parts. This speed allows for a 38-second cycle on components that previously took 50 seconds. On an annual scale, this efficiency frees up approximately 1,400 hours of manufacturing capacity without adding overhead.

Investment in high-performance tooling typically accounts for 3-6% of total company costs, but the recovery timeline is short in high-volume production. Beyond speed, these systems reduce the clamp tonnage requirements on machinery. This lowers energy consumption and reduces the wear-and-tear burden rates on the primary equipment, extending the life of the factory’s capital assets.

CNC Diamond-Blade Precision as a Labor-Saving Asset

Manufacturing precision directly dictates field labor profitability. Because labor often accounts for 40-60% of total stone project costs, eliminating non-productive time (NPT) on-site is the fastest way to improve ROI. Top Source Stone utilizes CNC diamond-blade edges to ensure consistent fitment, which removes the need for installers to manually trim stones during the wall assembly.

- Interlocking Systems: Z-Shape and S-Shape panels use a male-female connection to camouflage vertical joints automatically, removing the risk of visible “stepped” gaps.

- Color Consistency: We source from the same quarry vein per order to maintain 95% hue uniformity, preventing the hours crews usually spend sorting stones for color matching.

- Pre-fabricated L-Corners: Matching 90-degree corners eliminate the requirement for complex miter cuts on-site, allowing less-experienced installers to produce professional wall transitions.

- Installation Speed: Standard panels cover 10-15 sq. ft. per hour, roughly 10 times faster than hand-stacked loose stone.

By moving the technical complexity from the job site to the factory, developers can use smaller, less specialized crews. This shift reduces the “burdened rate” of labor—the true cost including taxes and insurance—which can be 4-8 times the material cost in manual framing and masonry. Precision-engineered panels turn a skilled masonry task into a modular assembly process.

Strategies for Reducing Non-Productive Time (NPT) for Field Crews

Minimize NPT by clustering job sites geographically and utilizing pre-fabricated Z-panels. Shifting labor from on-site fabrication to high-speed installation protects project margins and accelerates turnover.

Geographic Clustering and Task Sequencing

Travel time is a silent profit killer. When crews bounce between distant sites, “windshield time” inflates overhead without adding value to the project. Smart scheduling keeps teams in localized zones to maximize their active installation hours.

- Geographic Clustering: Group projects by zip code to reduce vehicle wear and fuel consumption.

- Afternoon Prep: Teams outfit trucks and confirm tomorrow’s schedule before leaving the shop to ensure an immediate rollout the next morning.

- Process Batching: Sequence similar tasks across multiple properties so crews stay in the rhythm of a single installation type.

- Energy-Based Scheduling: Block high-intensity tasks for the morning peak and save site cleanup or maintenance for the afternoon.

Eliminating On-Site Cutting with Pre-fabricated L-Corners

Traditional stone masonry often stalls at the corners. Manual 45-degree miter cuts are slow, dusty, and prone to error. Replacing loose stone with engineered components shifts the crew’s focus from fabrication to pure assembly.

- Pre-fabricated L-Corners: Use Top Source Stone matching 90-degree corners to bypass manual miter sawing and ensure perfect texture synchronization.

- CNC Precision: Install panels with CNC diamond-blade edges that provide a tight “male-female” interlock, removing the need for field adjustments.

- Z-Shape Panels: Deploy interlocking Z-panels to camouflage vertical joints and eliminate visible substrates without extra grouting time.

- Labor Optimization: Utilize project-ready solutions that allow tile installers or general crews to achieve master-mason results in 38% less time.

High-speed installation relies on reducing variables. By arriving on-site with pre-sorted batches from the same quarry vein and components that require zero cutting, contractors maintain a consistent pace and predictable labor costs.

Comparing Installation Efficiency: Z-Panels vs. Loose Stone

Z-panels install 10 times faster than loose stone, cutting labor costs by 40%. This shift allows tile setters to replace specialized masons, maximizing project margins.

Installation speed dictates the profitability of any large-scale masonry project. While loose stone offers high customization, the labor requirements often eat into the bottom line. Modern data shows that modular Z-panels cover 10 to 15 square feet per hour, whereas traditional hand-stacked methods barely reach a third of that pace.

Speed Benchmarks and Labor Resource Allocation

Labor typically accounts for 40% to 60% of total project expenditures in current masonry budgets. By switching to a modular system, project managers reduce the reliance on scarce, high-cost masons and can utilize standard tile setters instead. This shift effectively lowers the labor burden by $5 to $8 per square foot.

- Coverage Speed: Z-panels provide a 200% to 1000% increase in installation velocity over loose stone.

- Labor Cost Reduction: Modular systems cut total installation expenses by 30% to 40%.

- Resource Flexibility: Using tile installers instead of specialized masons saves significant overhead per square foot.

- Productivity Rate: Installers consistently hit 10-15 square feet per hour with interlocking panels.

CNC Diamond-Blade Precision and Interlocking Systems

Engineered panel specifications eliminate the technical hurdles that slow down traditional masonry. At Top Source Stone, we use CNC diamond-blade edges to ensure every panel fits tightly. This precision removes the need for on-site hand-chipping or sorting through crates for matching pieces.

- Seamless Technology: Z-Shape and S-Shape male-female connections camouflage vertical joints for a continuous architectural finish.

- Hue Uniformity: Same-batch quarry consistency ensures 95% color harmony across a single order.

- Pre-fabricated L-Corners: Matching 90-degree corners synchronize texture and color at transitions, eliminating the need for complex miter cuts.

- Interlocking Precision: CNC-cut edges ensure modular pieces fit tightly, concealing the installation substrate.

For dealers and wholesalers, these efficiencies translate directly into faster project turnarounds and protected margins. By providing a project-ready solution with matching corners and interlocking panels, we help your clients bypass the labor shortages currently affecting the masonry industry.

ofte stilte spørsmål

What is the average labor cost for natural stacked stone installation?

Professional labor for natural stone veneer typically ranges from $10 to $30 per square foot. Specialized naturstein projects often fall at the higher end of this scale, specifically between $20 and $30, because the weight of the material and the need for precision cutting require more skilled man-hours than manufactured alternatives.

How can I speed up the installation of wall corners?

Using pre-fabricated L-shaped corners is the most effective way to save time. These 90-degree pieces match the color and texture of the flat panels and eliminate the need for difficult miter cuts on-site. Combining these with Z-shape interlocking panels also helps hide vertical joints without extra effort.

Is hiring a specialized stone mason necessary for these projects?

A specialized mason ensures the stone stays bonded for decades. They use high-strength epoxy systems and understand how to manage moisture and local building codes. While general labor can handle basic tasks, a professional prevents common issues like stone delamination or water damage that can occur with improper installation.

How much material waste should I expect for a fireplace bump-out?

Budget for 10% to 15% additional material for complex areas like fireplace bump-outs. This buffer covers material breakage during transport and the specific cuts needed to wrap around the depth of the structure, which usually ranges from 12 to 24 inches.

What is the best crew size for a large 500sqm exterior project?

A crew of 5 to 7 workers is the industry standard for large exterior stone applications. Odd-numbered teams often maintain higher productivity by balancing the workload between those prepping the substrate and those setting the panels. The exact number depends on your required completion date.