Poorly executed 20. Flashing & Drainage systems are the primary cause of substrate rot and expensive liability claims in stone facade projects. When moisture traps form behind natural stone, the resulting anchor corrosion and freeze-thaw damage destroy project margins and long-term structural integrity.

This technical analysis solves these failures by pairing ASTM-standard freeze-thaw resistant minerals with CNC diamond-blade precision. Utilizing Z-Shape interlocking panels and matching L-corners ensures a ventilated cavity that protects the building envelope while maintaining 95% hue uniformity across the facade.

Why Exterior Flashing is the #1 Fail Point for Stone Durability

Flashing failure leads to water intrusion, causing freeze-thaw damage and anchor corrosion. In 2026, it remains the top risk for stone facade integrity.

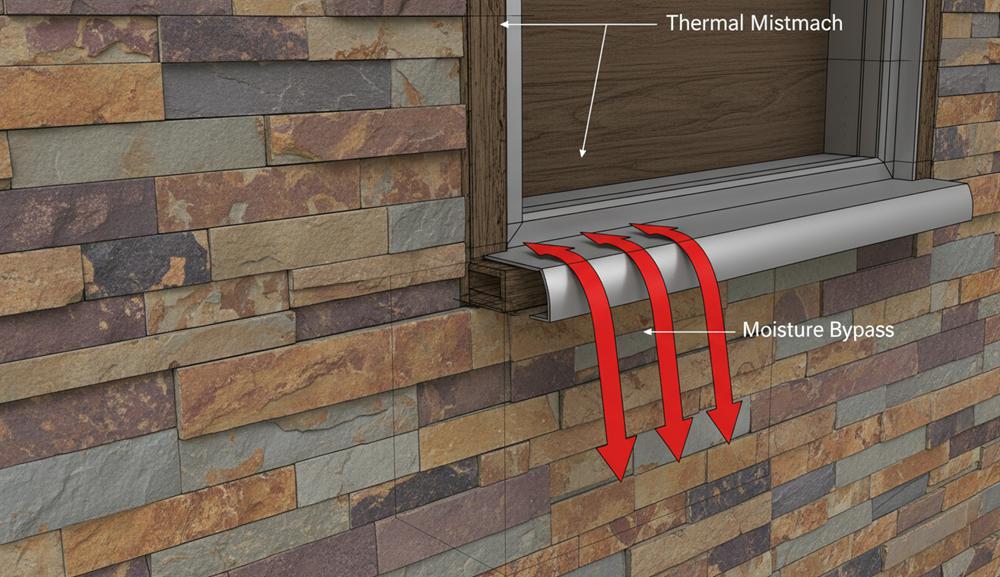

Thermal Movement and the Cycle of Moisture Intrusion

Metal flashing and rigid stone expand at different rates. When temperature swings hit, the metal cycles through physical changes that the unyielding stone cannot match. This creates a mechanical separation that invites moisture into the wall cavity, bypassing the primary cladding defense.

- Thermal Stress: Temperature fluctuations force metal flashing to expand and contract, eventually pulling it away from rigid stone surfaces.

- Moisture Bypass: Gaps created by thermal stress allow liquid water to bypass the exterior cladding and saturate the substrate.

- Failure Chain: Prolonged moisture exposure initiates anchor corrosion and degrades the critical bond between the stone and the wall.

Identifying these mechanics early is vital for long-term climate resilience. Once water enters the cavity, the internal environment stays damp, accelerating the decay of metal supports and structural sheathing.

ASTM-Standard Freeze-Thaw Resistance for Climate Resilience

Material selection acts as the second line of defense. Even with perfect flashing, steinpaneler must withstand the environmental pressures of extreme weather. Natural minerals offer the density required to resist internal pressure from moisture cycles.

- ASTM Standards: Toppkildestein materials meet ASTM-standard freeze-thaw resistance, preventing internal cracking when water bypasses flashing.

- Mineral Composition: Using 100% natural Quartzite and Slate ensures high salinity and humidity resistance in extreme 2026 weather conditions.

- Hydrostatic Control: UV-stable panels require professional flashing integration to prevent hydrostatic pressure from building behind interlocking Z-shape systems.

For B2B importers and project managers, specifying stone that maintains structural integrity under ASTM testing is non-negotiable. While the stone provides the aesthetic value and UV stability, the flashing integration determines the actual lifespan of the facade.

Designing Drip Edges to Redirect Water from the Stone Base

A drip edge is a physical break—typically a groove or metal protrusion—installed at the base of steinkledning to force rainwater to drop away from the building, protecting the foundation.

Mechanics of Deflection: Disrupting Surface Tension in Masonry

Water naturally clings to surfaces through surface tension. Without a physical interruption, rainwater running down a stone facade will follow the underside of horizontal ledges and soak into the wall cavity or foundation. This moisture migration is a primary cause of structural rot and masonry degradation.

- Flow Interruption: Physical breaks stop water from tracking back along the underside of sills and copings.

- Capillary Break: Drip edges reduce the risk of capillary action where water seeps into joints and structural substrates.

- Freeze-Thaw Protection: Ensuring water falls freely prevents the saturation of the stone base, which is vital for maintaining the integrity of natural quartzite and slate in cold climates.

- Stain Prevention: Controlled drainage eliminates the formation of unsightly calcium deposits and mineral “bleeding” on the facade.

CNC-Machined Drip Grooves and Proper Drainage Slopes

Reliable water redirection starts at the manufacturing stage. We use CNC diamond-blade precision to carve integrated drip grooves directly into the underside of natural stone sills. This creates a permanent, maintenance-free water break that outperforms surface-applied sealants or adhesive strips.

- Surface Inclination: Maintain a minimum outward slope of 5 to 10 degrees on all horizontal stone surfaces to facilitate gravity-led drainage.

- Groove Dimensions: CNC-carved grooves should be positioned at least 15mm to 20mm from the outer edge of the stone.

- Metal Integration: Use stainless steel or high-grade metal profile drip edges to channel water infiltrations outside the wall covering.

- Secondary Sealing: Install foam strips and high-performance sealants between the metal plate and the stone to prevent secondary water penetration.

By combining precise stone machining with correct installation slopes, contractors can ensure that water stays away from the building envelope. This technical approach is mandatory for 2026 construction standards to prevent the long-term saturation that leads to spalling and structural decay.

Premium Stacked Stone for Architectural Excellence

Integrating Weep Holes: Why Air-flow Behind the Stone is Mandatory?

Weep holes provide the essential drainage and ventilation needed to prevent moisture entrapment, structural rot, and surface efflorescence in exterior stone cladding systems.

Stone cladding systems are not waterproof. Rain, snow, and humidity eventually find a path behind the steinpaneler through joints or capillary action. Without a dedicated ventilation strategy, this moisture stays trapped against the substrate, leading to the failure of the entire wall assembly.

Managing Wall Cavity Ventilation to Prevent Decay

Trapped moisture creates a stagnant environment behind the steinfiner. This dampness triggers mold growth and biological degradation of the building’s substrate, often rotting wood sheathing long before the damage becomes visible on the exterior surface.

- Pressure Management: Internal hydrostatic pressure builds up from water accumulation. This pressure forces water deeper into the wall, causing mortar cracking and structural shifts over time.

- Airflow Specifications: Continuous airflow via 450mm spaced weep holes facilitates the rapid drying of condensation and wind-driven rain within the cavity.

- Substrate Integrity: Proper ventilation ensures the wall system dries efficiently, protecting the building substrate from the long-term moisture-related failures common in unventilated “reservoir” claddings.

Protecting ASTM-Standard Durability and Surface Aesthetics

Ventilation is about more than structural safety; it directly impacts the visual integrity of the naturstein. Proper drainage prevents mineral salts from migrating to the surface of the natural slate or quartzite, stopping the white, chalky residue known as efflorescence from appearing.

- Bond Protection: Efficient drainage protects the high-strength epoxy bond used in Top Source Stone panels from moisture-induced delamination, ensuring the stones remain securely attached to the backing.

- Freeze-Thaw Performance: Maintaining a dry cavity supports the freeze-thaw resistance required for ASTM-standard durability in North American climates, preventing the stone from cracking or spalling during winter cycles.

- Aesthetic Longevity: Airflow keeps the stone surface dry and clean, preserving the natural color consistency and 95% hue uniformity of high-quality quarry-sourced materials.

Material Specs: Metal vs. Polyurethane Flashing Performance

Metal provides rigidity but risks rust and pinholes. Polyurethane offers superior cold-weather flexibility and noise absorption, though it requires proper drainage to avoid standing water issues.

| Trekk | Metal Flashing | Polyurethane Sealant |

|---|---|---|

| Cold-Weather Flexibility | Rigid; prone to pulling away | Superior; stays elastic in extreme cold |

| Durability Issues | Rust and pinhole development | Degrades if exposed to standing water |

| Acoustic Performance | Generates vibration noise | Absorbs structural noise |

| Fabrication Cost | High; requires welding/machining | Low; eliminates custom machining |

Performance Trade-offs in Weatherproofing Materials

Traditional metal flashing creates significant durability hurdles in stone facade systems. We see metal develop pinholes and rust over time, which open hidden leak paths behind steinfiner. These gaps often go unnoticed until the substrate begins to rot.

- Thermal Movement: Polyurethane sealants handle extreme cold better than rigid metal, which tends to buckle or pull away during temperature shifts.

- Noise Reduction: Sealant materials actively absorb structural vibrations. Metal alternatives often generate distracting noise during operation or heavy winds.

- Fabrication Efficiency: Polyurethane allows for a faster install. It bypasses the expensive welding and precision machining needed for custom metal profiles.

- Longevity: While metal is the “standard,” polyurethane can outlast some metals by up to three times in specific environmental conditions.

ASTM Standards and Natural Stone Compatibility

Top Source Stone utilizes 100% natural minerals, meaning the flashing must match the stone’s chemical and physical properties. We strictly monitor material pairing to ensure the UV stability of our quarry-sourced stone remains uncompromised by flashing chemical leaching or failure.

- Freeze-Thaw Resistance: Our materials meet ASTM standards. This ensures flashing bonds stay intact even when temperatures cycle rapidly, preventing stone delamination.

- Coastal Protection: For projects in the Gulf or other humid regions, we require high salinity resistance to protect the substrate behind natural slate and quartzite panels.

- Color Consistency: Proper flashing integration prevents the “patchy” appearance caused by water infiltration and mineral bleeding.

- Moisture Control: Correct material selection stops water from getting behind the veneer, where it would otherwise cause spalling in naturstein minerals.

B2B buyers should focus on the specific environmental stressors of the job site. For instance, northern climates demand the cold-weather flexibility of polyurethane, while projects with potential standing water might still lean toward high-grade stainless steel to avoid sealant degradation.

How to Handle Roof-to-Wall Transitions with Stacked Stone Cladding?

Direct moisture away from the wall cavity by layering headwall flashing in a shingle-fashion sequence behind two layers of weather-resistant barrier (WRB).

Natural stone is a reservoir cladding. It absorbs and holds moisture, which means the transition where a roof meets a stone wall is a high-risk zone for leaks. Without a strict installation sequence, water seeps into the substrate, leading to mold and structural rot. We focus on a multi-layered defense to ensure the building envelope remains dry regardless of the weather conditions.

Layering Sequence for Headwall Flashing and Barriers

Managing water at the headwall requires a specific physical assembly. You cannot rely on sealants alone; the materials must overlap to use gravity as a drainage tool. This prevents moisture from reaching the wood sheathing or the interior of the structure.

- Through-wall flashing: Install metal or flexible membrane flashing at the headwall intersection before applying any steinfiner to block water penetration.

- WRB Overlap: Apply the weather-resistant barrier (WRB) over the vertical leg of the flashing in a downward-shedding fashion to guide moisture out.

- Clearance Gap: Maintain a small gap between the bottom of the steinkledning and the roof surface to stop capillary action and allow water to exit.

- Dual WRB Layers: Building codes for adhered steinfiner require two layers of WRB to protect the substrate from the high humidity typical of stone assemblies.

Utilizing Matching L-Corners for Sealed Wall Junctures

Vertical wall transitions at roof lines are often where generic installations fail. If the joints are loose, water finds a path. Top Source Stone engineered solutions simplify this transition by providing precision-fit components that close these vulnerabilities.

- 90-Degree L-Corners: Use pre-fabricated L-Corners to maintain texture synchronization and eliminate the messy gaps found in field-cut mitered joints.

- CNC Diamond-Blade Precision: Our panels feature CNC-cut edges that create tight, interlocking joints, significantly reducing water entry points near the roof line.

- Material Durability: Select freeze-thaw resistant quartzite or slate (like our Alaska Gray or Midnight Slate) to handle the temperature shifts and humidity of roof contact zones.

- Batch Consistency: We source from the same quarry vein per order, ensuring the wall panels and corner units maintain a 95% hue uniformity across the transition.

Following this technical sequence ensures the stone facade remains a long-term architectural asset rather than a maintenance liability. For B2B dealers, providing these specific installation guidelines alongside our “Big 10” inventory helps reduce client callbacks and protects project margins.

Final Thoughts

Poorly designed drainage is the primary driver of the structural rot that destroys stone facade ROI. By integrating CNC-machined drip grooves, 450mm-spaced weep holes, and a strict shingle-lapped flashing sequence, we move beyond mere aesthetics to provide a technically sound building envelope.

At Top Source Stone, we safeguard your project margins by pairing these elite installation protocols with ASTM-standard freeze-thaw resistant minerals. Our same-batch quarry consistency ensures that even the most complex technical transitions maintain a 95% hue uniformity, protecting your brand’s reputation for architectural excellence.

Secure your next facade project by verifying our material tolerances firsthand. We recommend requesting a physical sample kit or initiating a 300-square-meter trial order to evaluate our Z-Shape interlocking fitment and L-corner precision. Contact our technical team today to receive a project-specific flashing guide and high-definition pre-shipment verification photos.