Professional Vertical Installation & Slip Prevention protocols are the primary defense against gravitational creep, which causes 8–12 lbs/sq.ft natural stone panels to slump and ruin structural alignment. Failure to manage shear stress in high areas leads to expensive rework and safety liability on commercial job sites.

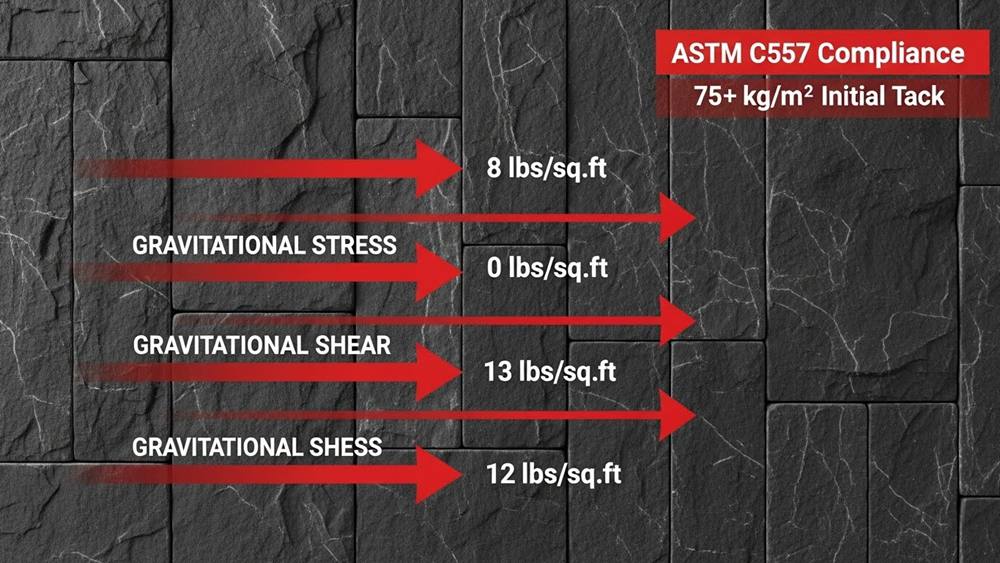

We utilize 75+ kg/m² high-tack adhesives and seamless Z-shape interlocks to secure natural quartzite and slate without excessive bracing. This analysis focuses on ASTM C557 compliance and freeze-thaw resistance to protect dealer margins and accelerate project delivery.

Slip Prevention: Using Support Shims and Temporary Bracing Systems

OSHA-compliant bracing and support shims prevent 8-12 lb natural stone panels from shifting during the curing phase, ensuring structural alignment and safety on high-cladding projects.

| Installation Parameter | Technical Requirement |

|---|---|

| Panel Weight (Natural Stone) | 8 lbs – 12 lbs per square foot |

| Temporary Bracing Resistance | 200 lbs (890 N) of force |

| Vertical Anchor Load | 22 kN capacity |

| Minimum Installation Temp | 40°F (4.4°C) |

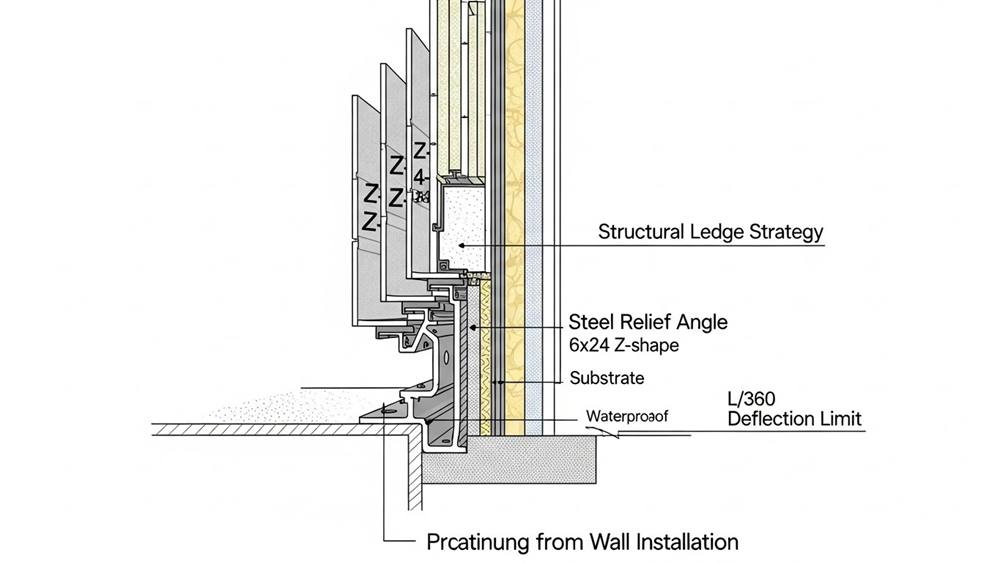

| Substrate Deflection Limit | L/360 total load |

OSHA Load Standards for Temporary Support and Bracing

Vertical installation projects in 2026 demand strict adherence to mechanical bracing protocols to counteract gravity while adhesives reach full bond strength. Failure to secure panels during the initial setting period often results in creep or total material collapse, especially on exterior facades subject to wind loads.

- Bracing Strength: Install temporary supports capable of resisting 200 pounds of force to comply with OSHA 29 CFR 1910.29 safety mandates.

- Load Capacity: Use shims and anchors rated for 22 kN vertical loads to prevent cladding failure on high-rise applications.

- Stable Access: Maintain a 4:1 ladder ratio and utilize locked castors on all work platforms to ensure a stable base during heavy panel placement.

- Friction Verification: Test substrate friction levels per ANSI/ASSP A1264.2-2022 to identify potential movement risks before applying mortar.

Structural Adhesive Specs for Natural Stone Panel Stability

While temporary bracing provides external support, the internal stability of the wall system relies on factory-applied bonding technology. Top Source Stone utilizes a high-strength structural adhesive system specifically engineered to handle the 8 to 12 lb per square foot load of 100% natural slate and quartzite.

- Z-Shape Interlock: Panels feature a precision-cut Z-shape design that distributes weight across the wall and removes visible vertical seams.

- Adhesive Performance: Factory-tested bonding systems resist freeze-thaw cycles, ensuring the stone does not delaminate in extreme climates.

- Standard Dimensions: We stock 6 inch x 24 inch panels in the Big 10 Inventory to ensure edge-fit precision during shimming.

- Batch Consistency: Pre-sorted stone batches maintain color uniformity, preventing “patchy” aesthetics on large commercial feature walls.

By combining mechanical shims with these engineered panel features, contractors reduce labor costs associated with repositioning slipped stones. This dual-layer approach ensures that once a panel is set, it remains plumb and secure through the entire curing cycle.

Adhesive Initial Tack and Adjustable Working Time

High-performance adhesives must provide 20-75 kg/m² of initial tack to prevent vertical slippage while maintaining a working window for precise Z-shape panel alignment.

| Performance Metric | Standard Adhesives | High-Performance Variants |

|---|---|---|

| Initial Tack (Grab) | 20-40 kg/m² | 75+ kg/m² |

| Temporary Bracing | Required for >15 kg/m² | Often eliminated |

| ASTM Compliance | General C557 | ASTM C557 & E72 (No-Sag) |

| Final Bond Strength | 1.5 – 2.0 MPa | 2.0 – 3.0 MPa |

Mechanics of Initial Tack in Vertical Panel Support

Vertical installation forces adhesives to counter gravity immediately upon contact. While standard products offer a baseline grab of 20-40 kg/m², Top Source Stone rough stacked stone panels often reach 55kg/m². This weight differential requires high-performance adhesives that exceed 75 kg/m² of initial tack to prevent material slide-down during the curing process.

Reliable vertical adhesion depends on these technical thresholds:

- Tack Thresholds: 75 kg/m² variants allow for brace-free installation of heavy quartzite and slate panels.

- Regulatory Standards: Compliance with ASTM C557 and ASTM E72 ensures no-sag performance under sustained vertical tension.

- Stress Distribution: High-tack formulations create a homogeneous bond interface, preventing localized failures at spot-application points.

- Support Requirements: Standard adhesives require mechanical shims or anchors for any panel exceeding 15 kg/m².

High-Strength Epoxy Resin and Bond Stability

Precision alignment is non-negotiable for seamless Z-shape and S-shape interlocking panels. Installers need a controlled adjustable working time to maneuver panels into place before the adhesive reaches its final set. We utilize high-strength structural epoxy resins specifically formulated for 100% naturstein to balance this immediate grip with necessary repositioning windows.

This technology secures natural quartzite and slate against the specific environmental pressures found in North American and European markets:

- Freeze-Thaw Resistance: Structural bonding prevents water intrusion that causes delamination in extreme cold.

- Z-Shape Alignment: Adjustable windows allow for the tight, grout-free joints required for professional ledger panel finishes.

- Curing Cycles: Controlled chemical reactions ensure the stone-to-backing bond remains permanent even under the thermal expansion of exterior facades.

- Load Transfer: The resin system effectively transfers construction loads to the substrate, maintaining plumbness over time.

Cold Weather Installation: Managing Slow Mortar Curing

Maintain mortar above 40°F to prevent freezing. Use preheated mixing water and Top Source Stone’s freeze-thaw resistant quartzite to ensure bond integrity and durability in sub-zero conditions.

Thermal Protection Protocols for Mortar Hydration

Standard masonry protocols require immediate action once ambient temperatures drop to 40°F (4.4°C). If mortar freezes before it reaches sufficient compressive strength, the chemical hydration process halts, leading to brittle joints and eventual bond failure in vertical stacks.

- Temperature Threshold: Initiate TMS 602 and IBC 2104.3 protocols when air temperatures fall below 40°F.

- Material Preheating: Heat mixing water and sand to maintain mortar between 40°F and 120°F during mixing and placement.

- Substrate Preparation: Remove all ice and snow from the wall; ensure stone units reach at least 40°F before application.

- Curing Protection: Cover new installations with thermal blankets or enclosures for 24 to 48 hours to prevent ice crystal formation.

Grout requires even stricter thermal control, needing a minimum placement temperature of 70°F to mitigate hydration delays. These procedural baselines prevent the common defect of joint cracking and help maintain early-age compressive strength.

Freeze-Thaw Resistant Quartzite and Structural Adhesive Stability

Material selection determines whether a facade survives extreme North American or European winters. While average stone might delaminate, 100% natural quartzite and slate offer the density required to resist internal water pressure during rapid freeze-thaw cycles.

- Material Grading: We utilize 100% natural quartzite and slate specifically graded for freeze-thaw resistance to prevent surface spalling.

- Bonding Technology: Our ledger panels use a high-strength structural adhesive system that maintains panel stability during thermal expansion.

- Moisture Mitigation: Applying professional-grade sealants prevents the stone from absorbing water that could freeze and cause internal stress.

- Backing Design: High-density panel backing ensures consistent contact with the mortar bed, even in slower-curing environments.

Top Source Stone produces these panels at a direct quarry source, ensuring batch consistency that wholesalers and dealers rely on for large-scale commercial cladding. This quality control minimizes the risk of vertical slip and ensures the 6″ x 24″ panels remain secure throughout the winter.

Premium Stacked Stone for Architectural Needs

The Necessity of Starting Installation from the Bottom Layer

Starting at the base creates a mechanical ledge that supports 8-12 lbs/sq.ft. steinpaneler, preventing gravitational slippage and ensuring Z-shape panels align perfectly without visible seams or adhesive failure.

Managing Gravitational Load in Vertical Applications

Vertical installasjon av stein involves managing constant downward pressure. For B2B projects where speed and precision impact margins, starting from the base is the only way to counteract the cumulative force of stacked materials. This sequence ensures the first row carries the load, protecting the bond integrity of the entire wall.

- Mechanical Support: The base row creates a structural ledge that carries the weight of all superior rows.

- Mortar Protection: A bottom-up sequence prevents cumulative downward force from compressing wet mortar joints or squeezing out thin-set.

- Level Control: Establishing a perfectly level first row is the standard for maintaining horizontal accuracy across large exterior facades.

Supporting 8-12 lbs Ledger Panels with Level Foundational Rows

Top Source Stone quartzite and slate panels are heavy, natural products. Unlike lightweight cement imitations, these 100% natural panels require immediate physical support to stay in place while the structural adhesive cures. If you start from the top, gravity will pull the panels down, causing them to sag and ruining the interlocking alignment.

- Weight Specs: Standard panels weigh between 8 and 12 lbs per square foot, while rough stacked stone reaches 55kg/m².

- Z-Shape Precision: The seamless Z-shape interlock relies on a stable foundation to prevent visible vertical seams or gaps.

- Adhesive Cure: Proper support allows the high-strength adhesive to bond without the panel shifting under its own mass.

- Material Standards: This method is mandatory for 100% natural Quartzite (HS 6802.9311) and Slate (HS 6803.0090) to ensure long-term stability.

Wholesalers and dealers must emphasize this “bottom-up” rule to installers to avoid liability for falling panels or failed inspections. Bypassing this step often leads to costly rework, as the weight of naturstein is unforgiving on unbraced vertical surfaces.

Case Study: Common Slippage Accidents in Column Installation and Prevention

Slippage occurs when vertical deviation exceeds 8-10mm or unbraced columns face 300-pound eccentric loads. L-shaped interlocking units and high-tack adhesives effectively stabilize these high-stress vertical surfaces.

Mechanics of Displacement and Eccentric Load Risks

Columns often fail during the hoisting or pouring phase due to poor alignment. If a column shifts more than 8mm vertically on a 6-meter run, load transfer becomes unpredictable. OSHA 1926 Subpart R mandates that column splices resist a 300-pound eccentric load at an 18-inch offset. If the bracing doesn’t meet this threshold, the steinkledning will likely crack or detach as the substrate shifts under weight.

Unbraced formwork gaps also lead to grout leakage, which compromises the structural bond between the stone and the column. Installers must verify these metrics before applying any natural stone veneer to ensure the substrate can handle the cumulative tension of the stack.

- Vertical Deviation Limit: ≤8mm for heights under 6m; ≤10mm for heights over 6m.

- Eccentric Load Capacity: Must withstand 300 lbs (136.2 kg) at an 18-inch offset.

- Anchoring Requirement: Minimum 4 anchor rods per column for structural stability.

Structural Stabilization via L-Corner Units and High-Strength Adhesion

Top Source Stone addresses these mechanical risks through precision engineering. While average adhesives provide 20-40 kg/m² of initial grab, high-performance structural systems achieve 75+ kg/m². This immediate tack is vital for our 8-12 lbs/sqft panels, as it eliminates the need for temporary bracing on vertical surfaces and speeds up the construction cycle for wholesalers and contractors.

We use a seamless Z-shape interlock design to distribute panel weight more effectively than standard rectangular cuts. For columns, the use of matching L-shaped corner units is a requirement, not an option. These units create a mechanical wrap-around bond that prevents lateral slippage, ensuring the stone stays plumb even if the column experiences minor vibrations.

- Panel Weight: 8 lbs – 12 lbs per square foot (Quartzite/Slate).

- Corner Tech: Matching L-shaped corner units for wrap-around mechanical bonding.

- Joint Design: Seamless Z-shape interlock to eliminate visible vertical seams.

- Adhesive Standard: 75+ kg/m² initial grab for support-free installation.

For B2B buyers, this system reduces labor costs and liability. By sourcing 100% natural stone directly from the quarry, we ensure batch color consistency across large-scale column projects. This prevents the “patchy” appearance that often triggers post-installation disputes and costly rework.

Final Thoughts

Choosing panels based on price alone overlooks the high cost of structural failure and liability in vertical cladding. Our direct quarry source panels utilize high-strength structural adhesive and freeze-thaw resistant quartzite to eliminate the slippage risks common with cement-imitation alternatives. Investing in inventory that meets ANSI standards protects your reputation and prevents the costly rework associated with 8-12 lb stone panels shifting during the curing process.

Request our technical catalog or a sample kit to verify the initial tack and batch color consistency of our Big 10 inventory firsthand. We support wholesalers with trial orders starting at 300 square meters to test local market response while maintaining high profit margins. Contact our B2B team today to discuss logistics or private label packaging for your next commercial project.

ofte stilte spørsmål

Vertical installation requires countering continuous shear stress with mechanical interlocking and high-performance adhesives. Top Source Stone ensures stability for panels up to 12 lbs per square foot through engineered backings.

Physics of Stone Cladding: Friction and Mechanical Bonding

Gravity exerts continuous shear stress on vertical steinpaneler. To prevent failure, the chemical and mechanical bond must exceed the total material weight. Standard industry practice focuses on surface friction, but vertical steinkledning requires a deeper structural connection to the substrate.

Mechanical bonding occurs when the adhesive penetrates the natural cleft textures of the stone and the pores of the substrate. ANSI/ASSP A1264.2-2022 standards highlight that surface contaminants directly impact this reliability. Clean, porous surfaces allow for maximum “initial tack,” which holds the stone in place during the critical curing phase.

- Shear Stress: Continuous gravitational pull requires bonds exceeding 12 lbs per square foot.

- ANSI Standards: ANSI/ASSP A1264.1 and A1264.2 govern surface characteristics and safety.

- Bonding Mechanism: Adhesive must penetrate natural cleft textures for mechanical lock.

- Initial Tack: Critical for preventing “creep” or sliding before the mortar sets.

High-Strength Structural Adhesive Systems for Natural Panels

Top Source Stone utilizes a high-strength structural adhesive backing to stabilize steinpaneler weighing between 8 and 12 lbs per square foot. This factory-applied system ensures that each piece of natural quartzite or slate maintains maximum contact with the installation mortar, reducing the risk of delamination in high-traffic commercial environments.

The Seamless Z-Shape Interlock design provides lateral support that helps distribute weight across the entire wall surface. This geometry prevents individual stones from slipping during the curing process, even in extreme 2026 climate conditions. These panels are engineered to be freeze-thaw resistant, protecting the bond from moisture expansion in cold climates.

- Panel Stability: Engineered for stones weighing 8-12 lbs/sq.ft (approx. 40-55kg/m2).

- Weight Distribution: Z-Shape Interlock provides lateral support to prevent vertical sliding.

- Climate Resilience: Freeze-thaw resistance prevents moisture from breaking the adhesive bond.

- Material Density: 100% natural slate and quartzite meet ANSI/ASSP A1264.1 requirements.

How should the bottom layer of stone be supported during vertical installation?

Support the bottom layer using relieving supports like continuous angles or clips. These transfer cumulative vertical loads to the structural slab. IBC standards recommend mechanical anchorage and relief supports at every story height or 20-foot vertical interval to prevent overloading the lower panels.

Which adhesives offer better initial grab for high-area installation?

High-performance adhesives with an initial grab of 75+ kg/m² are preferred for high-area installations. These formulations allow for vertical placement without temporary bracing. Standard adhesives (20-40 kg/m²) typically require supports for any panels exceeding 15 kg/m² to prevent slumping or material slide.

How should the mortar formula be adjusted in cold environments?

In environments below 40°F (4.4°C), heat the mixing water or sand to ensure the mortar stays between 40°F and 120°F during placement. Grout requires higher temperatures (70°F-120°F). Mortar must reach a compressive strength of at least 500 psi before being exposed to freezing to prevent permanent bond failure.

How to ensure the plumbness of the stone installation on columns?

Use visible plumb lines and L-shaped corner units for architectural stone columns to maintain alignment. For structural stone columns, industry standards mandate vibro-compaction to achieve 95% maximum dry density per ASTM D-1557, with horizontal center locations verified within 6 inches of the plan position.

How long should temporary support systems remain in place before removal?

Temporary supports must remain until structural stability is verified and the adhesive system achieves full load-bearing capacity. Removal hinges on inspection rather than a fixed timeline. For inclined surfaces or ladders, supports stay until slip resistance levels (PTV ≥36) are confirmed under wet and dry conditions.

How should the bottom layer of stone panels be supported during vertical installation?

Installers use relieving supports like continuous steel angles or clips at every floor slab or 20-foot vertical interval. This transfers the cumulative load of the stablet stein units to the building structure, preventing excessive weight from crushing the bottom layer or causing panel detachment.

Which adhesives provide the best initial grab for large-scale vertical projects?

High-performance hybrid polymers with an initial grab of 75+ kg/m² hold heavy steinpaneler without temporary bracing. Toppkildestein utilizes high-strength structural adhesive bonding in our manufacturing process to ensure each natural stone piece remains permanently secured to the panel backing.

What mortar adjustments are required for cold weather stone installation?

When temperatures drop below 40°F, heat the mixing water and sand to maintain a mortar temperature between 40°F and 120°F. The mortar must reach a minimum compressive strength of 500 psi before it is exposed to freezing to prevent permanent bond failure and structural cracking.

How can installers maintain plumbness and alignment on stone columns?

Use plumb lines and laser levels to verify vertical alignment at every two feet of height. Our seamless Z-shape interlocking panels assist in maintaining a straight line by eliminating visible vertical seams, while matching L-shaped corners ensure the column edges remain square and professional.

Does the manufacturer recommend specific sealers for high-moisture vertical areas?

Natural stone panels in kitchens or bathrooms require a high-quality, pH-neutral penetrating sealer. While stones like slate and quartzite are naturally durable, sealing prevents water absorption and staining in wet environments to ensure the installation maintains its appearance.

How long should temporary support systems remain in place before removal?

Temporary supports and shims should stay until the adhesive achieves its full load-bearing capacity, typically 24 to 48 hours. Removal only occurs after an inspection verifies that the bond strength is sufficient to support the weight of the stacked panels without risk of slippage.