Effective efflorescence removal protects a commercial property’s structural integrity and curb appeal from the compounding costs of salt-related decay. White, chalky deposits appearing on stone facades or retaining walls signal more than just an aesthetic issue; they indicate subsurface moisture migration that can lead to spalling or mortar failure. Facility managers face the risk of permanent masonry damage and decreased asset value when reactive cleaning replaces a proactive moisture management strategy.

This guide outlines the technical requirements for diagnosing the source of salt migration and selecting the correct intervention. We analyze why acidic cleaners often damage natural stone and provide a framework for implementing long-term drainage and sealing solutions. Identifying whether the minerals originate from the stone itself or the underlying mortar allows maintenance teams to stop the cycle of recurring white powder and maintain the masonry’s design life.

What is Efflorescence and Why is it Turning My Stone White?

Efflorescence represents a crystalline migration of water-soluble salts to the stone surface, serving as a visual diagnostic tool for moisture intrusion within the wall assembly.

Many B2B buyers and project managers mistake the white, chalky residue on natural stone veneer for permanent damage or product failure. This substance, known as efflorescence, consists of mineral salts left behind when water evaporates from the masonry surface. While the residue itself often wipes away, its presence confirms that capillary action is pulling moisture through the substrate, potentially disrupting the aesthetic of high-end stone installations.

Understanding the White Powdery Residue

The white powder typically appears as a fine, crystalline coating that obscures the rich textures of slate or quartzite panels. These salts dissolve in water during rain events or humid cycles, traveling through the porous network of the stone and mortar. Once the solution reaches the exterior face, the water evaporates into the atmosphere, leaving the solid minerals trapped on the surface.

- Soluble salts react with air to form a visible, hardened crust.

- The deposit indicates active moisture movement through the wall system.

- Ignoring these stains can lead to subflorescence, where crystals grow inside the stone and cause surface spalling.

The Role of Moisture in Salt Transport

Water serves as the primary transport vehicle for these minerals. Infiltration usually stems from poor drainage, lack of flashing, or improper moisture barriers behind the stacked stone panels. As building standards in 2026 emphasize tighter envelopes, managing the “wicking” effect of porous masonry has become a priority for preventing salt migration.

Natural Stone vs. Man-made Factors

While 100% natural stone—like the quartzite and slate sourced by Top Source Stone—is inherently durable and weather-resistant, the surrounding materials often introduce the salt. Portland-based mortars and concrete backup walls frequently contain free alkalis that contribute to staining. High-quality installations prioritize low-alkali cements and washed sand to limit the salt supply at the source.

Selecting dense, low-porosity materials like granite or high-grade quartzite significantly reduces the pathways for mineral leaching. Identifying whether the salt originates from the stone itself or the substrate allows for a more targeted remediation strategy, ensuring the longevity and visual integrity of the architectural finish.

Would you like me to detail the specific mortar additives that help reduce salt migration in stacked stone installations?

The Science of Salt Migration: Stone vs. Mortar Sources

Salt migration is a chemical transport process where moisture leaches water-soluble minerals from high-alkali binders and deposits them as crystalline efflorescence on the stone face.

Effective moisture management in 2026 requires a deep understanding of binder chemistry. Traditional Portland cement remains a primary source of sodium and potassium salts. However, the industry’s shift toward alkali-activated materials (AAMs) to reduce carbon footprints has introduced new challenges. While AAMs offer environmental benefits, our technical assessments show they often release higher salt loads into adjacent porous stones compared to standard mixtures. This initial salt load dictates the severity of visible white staining during the curing and weathering phases.

| Material Source | Risk Level | Primary Salt Contribution |

|---|---|---|

| Portland Cement (High Alkali) | High | Sodium & Potassium Sulfates |

| Alkali-Activated Materials (AAMs) | Critical | Soluble Alkali Carbonates |

| Low-Alkali Mortar (ASTM C150) | Low | Minimal Trace Residue |

Porous Stone Facilitation of Salt Transport

Natural stone panels act as a conduit rather than a barrier. Porous stones like sandstone or specific quartzite layers possess high capillary action, which wicks moisture-carrying salts from the mortar substrate to the surface. Density plays a decisive role here; tighter stones like those in our Top Source Stone “Big 10” inventory—such as Sierra Blue or Midnight Slate—offer higher resistance to this wicking effect compared to lower-density alternatives. We utilize CNC diamond-blade precision to ensure tight interlocking, which limits the exposed mortar surface area and reduces the moisture paths available for salt travel.

Material Compatibility and Restoration Gaps

Engineers often face a compatibility gap between modern high-strength binders and heritage or natural stone surfaces. In 2026, we prioritize modified mortar formulations that align with the stone’s breathability. Using unwashed sand or high-mineral mixing water during installation introduces external salts that compromise even the highest quality stone. Our current methodologies help predict these movement patterns through pre-construction salt-load modeling, ensuring that the interface between the substrate and the natural stone panel remains stable over long-term exposure cycles.

Would you like me to analyze the specific porosity ratings for the “Big 10” stone models to help you select the most resistant material for your next project?

Elevate Your Inventory with Premium Ledger Panels

Safe Removal: Why Acidic Cleaners Can Be Dangerous?

Utilizing aggressive acidic cleaners for rapid salt removal represents a high-risk maintenance error that can lead to permanent mineral oxidation and surface etching on natural stone.

The Risk of Chemical “Burning” and Etching

Natural stones like marble and certain slates contain calcium carbonate or sensitive iron minerals that react violently with acids. Strong acidic solutions—including common muriatic acid—strip away the stone’s natural luster and create a “burned” or bleached appearance. This damage is often irreversible, requiring expensive professional honing or full panel replacement to restore the original aesthetic.

Subsurface Resin and Mortar Degradation

Our Top Source Stone panels utilize high-strength epoxy resins for durability. Harsh acids can penetrate the stone’s pores and weaken these chemical bonds, leading to individual stone strips detaching from the backing. Furthermore, acid runoff can dissolve the lime in the surrounding mortar joints, creating more soluble salts and actually worsening the efflorescence cycle in the long run.

-

Prohibited: Muriatic acid, undiluted vinegar, and citrus-based industrial cleaners.

-

Recommended: Dry-brushing with stiff nylon followed by pH-neutral efflorescence removers.

-

Safety Protocol: Always pre-wet the stone with clean water before applying any cleaner to prevent deep chemical absorption.

Preventing Recurrence: Sealing and Drainage Solutions

Stopping efflorescence permanently requires a dual-track strategy: chemically blocking moisture at the stone surface and architecturally diverting water away from the wall assembly.

Applying Hydrophobic Sealants for Surface Protection

High-quality hydrophobic sealants create a chemical barrier that stops liquid water from carrying dissolved salts into the stone pores. For natural stacked stone, we recommend penetrating sealers (silane/siloxane blends) rather than film-forming coatings. Penetrating sealers move deep into the mineral substrate, providing up to 10 years of weatherproofing without trapping internal moisture. Trapped moisture behind a non-breathable film often causes surface spalling or internal salt deposits, which can lead to more severe structural degradation over time.

Applying these sealants immediately after the stone installation simplifies long-term maintenance. In regions with high salinity or humidity, such as the Gulf or coastal areas, sealing is a non-negotiable step to preserve the aesthetic integrity of materials like our Alaska Gray or Glacier White quartzite. These sealers maintain the natural cleft finish while ensuring the stone remains “freeze-thaw resistant,” a critical standard for North American and European climates.

| Prevention Strategy | Technical Mechanism | Primary Benefit |

|---|---|---|

| Penetrating Sealants | Blocks liquid water while remaining vapor-permeable. | Prevents salt migration without surface peeling. |

| Capillary Breaks | Physical barriers at the wall base to stop wicking. | Eliminates “rising damp” from groundwater. |

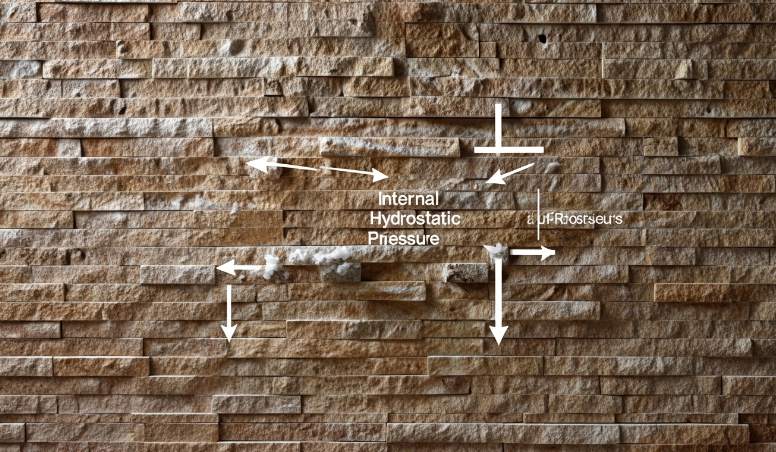

| Architectural Flashing | Diverts runoff away from the stone facade. | Reduces hydrostatic pressure behind panels. |

Optimizing Architectural Drainage and Flashing Design

Effective water management starts with architectural details that keep stone dry. Overhanging roofs, cornices, and properly sloped wall caps protect the vertical stone surface from direct rain exposure. Without these details, water pools on top of ledgestone and seeps into the substrate, inevitably leading to mineral leaching.

- Install a robust Water Resistive Barrier (WRB) behind the stone to ensure any moisture that bypasses the facade drains downward.

- Use professional flashing systems at all transitions, especially where the stone meets windows, doors, or the roofline.

- Ensure the surrounding grade slopes away from the masonry to prevent groundwater from pooling against the wall base.

Eliminating Infiltration Paths Through High-Quality Construction

Construction techniques determine the longevity of the installation. Using low-alkali cement in the mortar mix significantly reduces the initial salt content available to form efflorescence. Installers should also focus on dense, tooled joints and mechanical grout consolidation to minimize the porosity of the mortar layer. This physical density makes it harder for moisture to find a path to the surface.

For B2B projects involving large-scale facades, we provide “Project-Ready” solutions, including matching L-shaped corners that ensure tight seams and consistent texture. These precision-cut corners, manufactured with CNC diamond-blade technology, reduce the number of exposed joints where water can penetrate. By eliminating moisture sources at the design and installation stages, companies can avoid the high costs of post-installation remediation and restoration.

When to Call a Professional for Efflorescence Restoration?

Persistent mineral crusting often signals deep-seated moisture cycles or subflorescence that require professional diagnostic tools to prevent permanent stone spalling.

Surface-level salt deposits often brush away during dry weather, but a thick, calcified crust indicates a chronic moisture issue that simple cleaning cannot resolve. Experts examine the density of the buildup to differentiate between superficial efflorescence and cryptoflorescence—salt crystallization occurring inside the stone pores. This internal pressure can lead to cracks and surface delamination if the source of water is not identified and diverted.

Assessing Extensive Mineral Buildup and Structural Risks

We evaluate the thickness of the mineral crust to determine if standard removal methods will suffice or if advanced restoration is necessary. A professional inspection in 2026 focuses on identifying whether the white staining is a symptom of underlying drainage failures or structural leaks that threaten the masonry’s integrity. Ignoring these signs can lead to cascading damage in commercial and residential stacked stone installations.

- Technicians use specialized moisture sensors to detect water levels behind stone panels without causing surface damage.

- Inspections identify salt migration pathways originating from incompatible mortar or failed moisture barriers.

- We determine if the mineral deposits are masking more serious issues like rising damp or hydrostatic pressure.

Eco-Friendly Removal and Damage-Resistant Techniques

Modern stone restoration has shifted away from harsh muriatic acids that etch the surface of natural quartzite and slate. Specialists now employ media blasting or soft washing techniques tailored to the specific hardness and porosity of the material. These methods remove salts efficiently while preserving the stone’s natural cleft and texture. Using pH-neutral formulas ensures that the cleaning process does not introduce new reactive minerals into the masonry system.

- We apply proprietary, non-acidic cleaners that dissolve salts without damaging the surrounding landscape or vegetation.

- Precision cleaning methods protect the unique colors of “Big 10” inventory items like California Gold or Silver Blue.

- Professional services prioritize worker safety and environmental compliance through low-risk, sustainable formulations.

Long-Term Prevention and Aesthetic Value Preservation

Restoration goes beyond simple cleaning by implementing barrier solutions that prevent the return of mineral stains. Experts apply high-grade, breathable penetrating sealants that block liquid water while allowing internal vapor to escape. This “breathability” is vital for natural stone; trapping moisture behind a non-permeable film-forming sealer often causes the stone to flake or the sealer to turn a cloudy white, worsening the original problem.

- We provide a comprehensive strategy for moisture management, including advice on flashing repairs and drainage adjustments.

- Professional sealing protects the investment by maintaining the deep textures and rich hues of natural stone for years.

- Expert restoration revives the property’s curb appeal and preserves the structural durability of the wall system.

Conclusion

Managing efflorescence protects the aesthetic value of ledgestone and the underlying masonry structure from moisture-related degradation. Selecting appropriate cleaning methods and drainage solutions prevents recurring salt deposits that can compromise architectural finishes. These preventive measures ensure high-performance facade systems remain durable and visually consistent across large-scale commercial installations.

If you require technical guidance on selecting high-density natural stone with superior humidity resistance, we provide project-specific material consultations for our B2B partners. You can view our range of weather-resistant quartzites and slates in our latest product catalog.

Często zadawane pytania

Why is my stone wall turning white?

The white substance on your stone wall is known as efflorescence. It occurs when moisture travels through the stone or masonry, dissolving naturally occurring mineral salts along the way. When that water reaches the surface and evaporates, it leaves the salt behind as a white, powdery residue. Its presence typically signals a need for better moisture management or drainage.

How to remove white powder from stacked stone?

To remove efflorescence from stacked stone, start by using a stiff-bristled, non-metallic brush to dry-scrub the surface. If the powder remains, use a specialized efflorescence remover or a mild, pH-neutral stone cleaner. Avoid using high-pressure washers, as they can force more moisture into the stone, potentially causing the white powder to return as the wall dries.

Is vinegar safe for removing stone salt stains?

No, vinegar is not safe for use on most natural stone surfaces. Vinegar is highly acidic and can cause permanent etching or “burning” on stones like limestone, marble, and travertine. Instead of vinegar, utilize a professional-grade stone cleaner or a diluted efflorescence treatment designed specifically for masonry to ensure the structural and aesthetic integrity of the stone remains intact.

Does sealing stone prevent efflorescence?

A high-quality, breathable (penetrating) sealer can significantly reduce the risk of efflorescence by preventing liquid water from entering the stone’s pores. However, sealing is most effective when used as part of a comprehensive moisture management strategy that includes proper vapor barriers and drainage. It is crucial to ensure the stone is completely dry and free of salts before the sealer is applied.

Can efflorescence damage the structure of the stone?

Yes, if left unaddressed, the processes that cause efflorescence can lead to structural damage. When salts crystallize inside the stone’s pores rather than on the surface—a process called sub-florescence—the resulting internal pressure can cause the stone to crack, spall, or crumble. Addressing efflorescence early prevents these cascading structural issues and ensures the longevity of the installation.