Developing a robust stone sample strategy serves as the primary defense against lost showroom revenue and high return rates caused by material dissatisfaction. While digital catalogs offer convenience, they fail to bridge the sensory gap that often leads a buyer to choose a cheaper, synthetic alternative over high-margin natural stone. When a client cannot feel the weight or the unique tectonic profile of a product, the risk of a cancelled order or a mismatched project expectation increases significantly, impacting the bottom line of a B2B distribution model.

This guide provides a technical roadmap for leveraging physical tactile experiences to displace faux stone competitors. We examine the psychological triggers of the sensory gap, outline a standard operating procedure for sample logistics, and provide specific scripts for converting faux-interested buyers through hands-on comparison. By treating sample management as a precision sales tool rather than a clerical task, showrooms can stabilize their supply chain expectations and improve conversion metrics across all natural stone product lines.

Sales Psychology: The “Sensory Gap” Between Real and Fake Stone

Closing the sale on premium ledgestone requires moving beyond visual aesthetics to leverage the tactile “sensory gap” that separates 100% quarried minerals from synthetic concrete imitations.

Authentic Texture vs. Pigmented Concrete

The fundamental value proposition of natural stone rests in its geological origin. While manufactured “faux” stone relies on repetitive molds and surface-level pigments, our natural slate and quartzite panels offer non-repeating textures shaped by tectonic pressure. These materials maintain absolute color integrity even under intense UV exposure, whereas artificial concrete products often suffer from pigment degradation and “chalking” over a five-to-ten-year cycle.

| Feature | Top Source Natural Stone | Manufactured Concrete “Stone” |

|---|---|---|

| Composition | 100% Quarried Slate/Quartzite | Pigmented Lightweight Concrete |

| UV Stability | Permanent (No Fading) | Likely to fade over 5-10 years |

| Pattern Variance | Infinite (Unique per panel) | Limited (Repeating mold cycles) |

Weight also plays a critical role in buyer psychology. We engineer our panels to hit a “sweet spot” of 8-13 lbs/sqft. This provides enough heft to signal high-end durability and structural substance to the client, while remaining light enough for standard wall substrate requirements without expensive structural reinforcement.

Tactile Credibility and Property Value

High-dimension surfaces like our “Rough Series” create dramatic shadow lines that synthetic products cannot replicate. When a prospect runs their hand over the cold, dense surface of a natural marble or quartzite panel, they receive an immediate sensory confirmation of luxury. This tactile feedback bridges the gap between a “renovation” and an “asset upgrade.” Real stone installation directly correlates with higher property appraisal values, whereas man-made composites are often viewed as “moderate value” temporary finishes.

Eliminating Buyer Friction with Manufacturing Transparency

We remove the common fear that natural stone is “irregular” or “difficult” by applying CNC diamond-blade precision to every edge. This industrial accuracy ensures that while the face remains organic, the fit is modular and predictable. Our three-stage inspection process guarantees that the 95% hue uniformity we promise is what arrives at the job site.

To address long-term durability concerns, we utilize high-strength epoxy resin to bond the stone strips into our signature Z-shape interlocking panels. This system eliminates visible vertical grout lines, solving the “stepped” gap issue prevalent in cheaper imitations. By showcasing these engineering standards, you shift the conversation from price-per-foot to a long-term investment in architectural integrity.

Why Digital Photos Fail to Capture Natural Stone Texture

Digital imaging lacks the dynamic range and physical depth required to replicate the tactile complexity and shadow play of natural split-face stone.

Limitations of Sensor Resolution and Dynamic Range

Standard digital photography struggles to reproduce the intricate depth found in natural stone surfaces like our Rough Series. Digital sensors prioritize a flat focal plane, which works against the varied topography of genuine ledgestone. This technical limitation results in a visual compression that fails to represent the physical reality of the material.

- Digital sensors often flatten the dramatic shadows and 1.75-inch thickness variations inherent in natural split-face stone.

- Highlight clipping in bright areas and lost detail in shadows prevent buyers from seeing the authentic texture of slate and quartzite.

- Standard 2D images fail to convey the tactile feel that defines the value of genuine 2026 stone products over flat printed alternatives.

The Challenge of Color Calibration and Lighting Consistency

Variations in screen settings and environmental lighting lead to a significant disconnect between online images and the physical stone appearance. Without standardized calibration, a photo taken in a studio will never match the reality of a project site. These discrepancies often lead to mismatched expectations during the procurement process.

- Uncalibrated displays fail to meet D50/D65 color standards, causing natural marble veining to look artificial or discolored.

- Ambient light in photoshoots can mask the subtle crystalline glisten found in high-quality quartzite panels.

- Metamerism causes the stone to look different under warehouse LEDs versus natural 2026 sunlight, a gap photos cannot bridge.

3D Depth Perception vs. 2D Representation

Stone products like the Pencil Series rely on linear depth and shadows that vanish in two-dimensional photography. The human eye perceives depth through binocular vision and movement, which a fixed lens cannot replicate. This makes physical samples indispensable for professional architectural specifications.

- Standard photography captures only a single plane, missing the multi-layered complexity of ułożony kamień panels.

- The natural flow of 10-12 rows of stone strips requires physical movement and light shifts to be fully appreciated by designers.

- Digital noise in high-ISO photos often blurs the precise CNC diamond-blade edges that ensure our panels interlock perfectly.

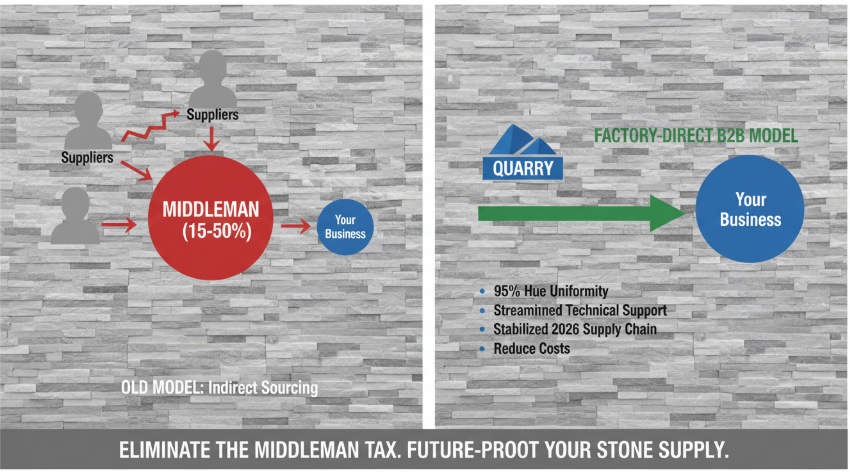

Factory-Direct Stacked Stone for Architectural Needs

Implementing an Effective Sample Program for Your Showroom

Showrooms that integrate high-CRI lighting with tactile Z-shape interlocking displays reduce sales cycles by up to 41% by bridging the sensory gap between digital browsing and physical procurement.

Success in natural stone distribution depends on how effectively a showroom translates raw material into a design solution. B2B buyers—architects, developers, and retailers—require more than just a pallet of stone; they need a controlled environment that validates the color depth and structural integrity of the product. By focusing on physical precision, showrooms eliminate the “option paralysis” often associated with the high natural variation found in slate and quartzite.

Optimizing Physical Tactility and Visual Precision

Lighting dictates the perceived value of natural stone. We recommend using high-CRI lighting (90+ CRI) to accurately reveal the mineral nuances in our Alaska Gray and Midnight Slate series. Natural stone possesses a depth that man-made “faux” products cannot replicate, but poor showroom lighting often flattens these textures. Organizing samples by series—Flat, Rough, Pencil, or Marble—allows designers to contrast modern minimalism with rugged traditionalism efficiently.

| Display Element | Technical Standard | B2B Buyer Benefit |

|---|---|---|

| Showroom Lighting | 90+ CRI (D50/D65 Standards) | Ensures color matching accuracy for site specs. |

| Panel Configuration | Z-Shape Interlocking (CNC Cut) | Demonstrates seamless joints and easy installation. |

| Weight Education | 8-13 lbs/sqft (Thin-Set Ready) | Validates “no-footing” structural cost savings. |

A critical component of the hands-on experience involves our interlocking Z-shape system. Showrooms should provide loose panels that contractors can fit together manually. This demonstrates the CNC diamond-blade precision that eliminates visible vertical gaps, a primary concern for high-end residential projects. Feeling the “male-female” connection system firsthand builds more confidence than any digital brochure.

Integrating Digital Tools with Physical Stone Assets

Modern B2B workflows require a bridge between the physical stone and the digital drawing board. We equip each stone panel with QR codes that link directly to 2026 digital catalogs and technical specifications. This allows designers to download high-resolution project galleries or AR visualization tools while standing in front of the physical display. By overlaying the Rough Series onto their own site photos, clients move from “interest” to “order” in a single session.

Inventory transparency is equally vital. We recommend that showrooms update digital inventory trackers frequently. When a designer knows the current availability of specific batches—especially for the “Big 10” North American colors—they can specify Górny kamień źródłowy with the certainty that the material will arrive at the job site on schedule.

Streamlining Distribution and Brand Building

Effective logistics support both immediate showroom sales and long-term brand loyalty. We offer customized OEM/ODM sample boxes that feature your distributor logo, reinforcing your local authority while utilizing our factory-direct pricing. Providing high-intent designers with standard 6” x 24” panels or L-shaped corner pieces for home evaluation removes the final friction point in the decision process.

- Maintain a stock of 12″ x 12″ large-format samples for comprehensive color evaluation.

- Use educational signage to highlight the “no-footing” advantage of our lightweight 8-13 lbs/sqft panels.

- Incentivize sample purchases by offering credits toward full 20GP container orders.

By positioning the showroom as a technical resource rather than just a retail space, you align with the needs of the professional tier. Our “Same-Batch Quarry Consistency” ensures that the stone delivered to the site matches the visual benchmarks set by your showroom displays, protecting your reputation and your margins.

Converting “Faux-Interested” Buyers with Natural Stone Hands-on

Physical product interaction removes buyer hesitation by demonstrating how modular natural stone panels solve the structural and aesthetic failures inherent in manufactured imitations.

Showcasing Full-Scale Panel Interlocking Systems

Small stone swatches often fail to communicate the continuity of a finished wall, leading to buyer hesitation and project delays. We solve this by displaying full 6” x 24” panels that allow clients to see the Z-shape interlocking system in action. This “male-female” connection system uses CNC diamond-blade precision to camouflage vertical joints, creating a seamless architectural finish that digital renders cannot replicate.

| Technical Feature | Top Source Natural Stone | Manufactured “Faux” Stone |

|---|---|---|

| Material Composition | 100% Natural Slate, Quartzite, or Marble | Pigmented Concrete / Polyurethane |

| UV Stability | Inherent mineral stability; zero fading | Subject to pigment degradation and peeling |

| Installation Edge | CNC Precision Interlock (Z-Shape) | Standard straight or molded edges |

| Heat Resistance | Non-combustible; ideal for fireplaces | Limited thermal thresholds; melting risk |

Material Resilience Tests for Weathering and UV Exposure

Buyers frequently confuse natural stone with cheaper pigmented concrete alternatives until they witness a side-by-side durability test. Authentic stone maintains its color integrity indefinitely because the hues are mineral-based rather than surface-applied. We contrast our panels with manufactured “cultured” stone to prove why real minerals do not fade under 2026 UV standards. Hands-on interaction also allows clients to feel the high-strength epoxy resin bond, which ensures individual stone pieces remain attached even in high-salinity or high-humidity environments.

Contractor-Focused Demonstrations of Lightweight Installation

Converting a skeptic requires proof of labor savings. We provide mock-ups showing that real stone panels, weighing only 8-13 lbs/sqft, can be installed without the heavy structural costs of traditional masonry. No additional footings or structural ledges are necessary for these retrofits. Trials with our pre-fabricated L-shaped corner pieces demonstrate how to avoid complex miter cuts on-site. This specific engineering reduces total labor time and ensures a professional wrap-around finish on both interior and exterior surfaces.

Presenting Real Stone as a High-Yield Property Investment

Faux stone is a cost-saving measure, but natural stone is a value-adding asset. We guide buyers to view the material as a permanent upgrade to property equity rather than a temporary finish. Our Marble and Pencil series create high-impact feature walls that directly increase appraisal value. By showing how low-maintenance natural stone stays clean with simple pH-neutral solutions, we remove the maintenance anxiety that often stops a sale. Direct manufacturer transparency ensures buyers understand the quality control journey from the quarry layer to the final crated product.

Managing Sample Logistics for B2B Clients

Efficient B2B sample logistics require a transition from manual dispatch to a technology-driven supply chain that ensures inventory visibility and hardened transit protocols for high-volume distributors.

High-volume B2B operations demand more than standard shipping; they require integrated systems that eliminate fulfillment bottlenecks. We use digital tracking and inventory platforms to provide real-time visibility for distributors and designers. This data-driven approach allows partners to confirm availability instantly, moving away from manual spreadsheets that often lead to human error and project delays.

Optimizing Inventory and Order Fulfillment Systems

Automated, touchless ordering processes are essential for maintaining the speed required in the 2026 construction market. By integrating our fulfillment systems directly with distributor needs, we reduce the time from sample request to dispatch. This efficiency ensures that critical series remain in constant rotation for showroom displays and client meetings.

- We use digital tracking platforms to provide real-time inventory visibility for distributors and architects.

- A shift toward automated, touchless ordering reduces fulfillment bottlenecks and eliminates manual data entry errors.

- Strategic stock levels of core series like Alaska Gray and Carbon Black Midnight Slate ensure that 2026 project timelines remain on track.

Carrier Selection and Transportation Management

Effective logistics rely on optimized carrier partnerships and protective packaging to ensure samples arrive in pristine condition. We coordinate multiple transportation modes through a central Transportation Management System (TMS) to balance cost control with delivery speed. This oversight is vital for managing our annual 200+ container shipments while maintaining the integrity of each individual sample.

- Our logistics team manages multiple transportation modes via a central TMS to optimize shipping routes and costs.

- We implement reinforced packaging protocols, using 5-ply export-grade cartons and fumigated wooden crates to survive international transit.

- Strategic loading techniques minimize transit risks and movement, protecting the delicate edges of natural stone panels.

B2B Strategic Alignment and Custom Solutions

Customizing logistics and branding helps our partners build their local market presence and scale efficiently. We align our supply chain forecasting with major B2B contract cycles to prevent stockouts during peak design seasons. This strategic synchronization ensures that when a large-scale project moves from the design phase to implementation, the material is ready for immediate dispatch.

- OEM and ODM options provide sample boxes featuring the distributor’s own logo and company branding to build local authority.

- We synchronize supply chain forecasting with B2B contract cycles to ensure inventory is available during peak procurement periods.

- Direct-from-factory logistics support large-scale projects requiring custom panel dimensions or specialized finishes.

Conclusion

Bridging the sensory gap through physical samples allows showrooms to prove the superior texture and UV stability of natural stone over synthetic alternatives. High-precision manufacturing and batch consistency from direct quarry sources ensure that the tactile experience translates into a reliable, high-margin architectural finish. This hands-on approach builds trust with buyers while protecting the long-term integrity of B2B inventory investments.

Review your current showroom display or request a physical sample kit from Górny kamień źródłowy to experience the interlocking precision of our Big 10 inventory. Contact our team to discuss private label options and container-level logistics for your next project.

Często zadawane pytania

How to get stacked stone samples?

You can obtain stacked stone samples by requesting them directly through manufacturer websites, visiting local masonry supply yards, or contacting architectural representatives. Most suppliers offer “sample boxes” or individual swatch pieces (typically 4×4 or 6×6 inches) that can be shipped directly to your office or project site to evaluate color and texture in your specific lighting environment.

Why are stone samples important for sales?

Samples are critical because they bridge the “sensory gap” between digital images and physical reality. In stone sales, buyer confidence is built through tactile and visual experiences. Providing a physical sample leverages sensory psychology, allowing the customer to feel the authentic texture and see the depth of the stone, which directly influences purchasing decisions and reduces the credibility gap between engineered and natural materials.

Can I get a full-size panel sample?

Yes, most professional suppliers provide full-size 6″ x24″ ledger panels upon request. While small swatches are useful for basic color matching, a full-size panel is the industry standard for verifying the interlocking mechanism and understanding the full range of tonal variation and “stagger” present in the product before committing to a bulk order.

How to display stacked stone in a showroom?

Effective showroom displays should utilize immersive, touch-enabled “vignettes” that mimic real-world applications like fireplaces or accent walls. Use high-CRI (Color Rendering Index) LED lighting directed at an angle to accentuate the shadows and three-dimensional texture of the stone. Providing side-by-side comparisons between different finishes also helps clients navigate the sensory differences between product lines.

Does natural stone look different than the sample?

Natural stone will always exhibit inherent variations in color, veining, and mineral deposits that may not be fully captured in a single sample. While samples provide a highly accurate representation of the general aesthetic, the final installation will have unique characteristics. This transparency in presentation is vital for managing consumer expectations regarding the organic authenticity of the product.