Site Logistics determines whether a large-scale masonry project remains profitable or suffers the 5% schedule growth typical of poorly managed staging areas. Inefficient material placement and delivery bottlenecks increase labor fatigue and risk on-site accidents, creating financial liabilities for construction managers.

We mitigate these risks by standardizing 110cm x 110cm plywood crates and maintaining the 17.5-ton USA port standard for predictable handling. Our use of pre-fabricated L-corners and CNC diamond-blade panels eliminates manual cutting, reducing on-site waste streams and ensuring architectural consistency across every work zone.

Strategic Staging: Preventing Accidents and Bottle-necks on Site

Strategic staging organizes material placement to remove site bottlenecks. Planning delivery routes and specific storage footprints reduces schedule growth while preventing common job site accidents.

| Staging Component | Top Source Stone B2B Standard |

|---|---|

| Crate Dimension | 110cm x 110cm Plywood |

| Weight Strategy | 17.5-Ton (USA Port Standard) |

| Corner Logistics | Pre-fabricated L-Corners |

| QC Verification | Pre-shipment Visual Reports |

Optimizing Site Layout for Movement and Safety Infrastructure

Site congestion is a primary driver of project delays and safety incidents. By organizing the physical layout before the first shipment arrives, you ensure that high-volume material transit doesn’t interfere with active work zones.

- Operational Coordination: Map delivery routes and equipment placement before stone arrival to prevent trades from overlapping.

- Access Control: Establish specific ingress points and safety signage to protect workers during heavy material movement.

- Phased Sequencing: Move staging areas to follow construction stages, keeping materials within reach of the installers.

- Efficiency: Place heavy ułożony kamień crates near active work zones to minimize movement waste and operator fatigue.

A dynamic layout adapts to the project’s needs. Shifting your storage footprint as walls are completed maintains a safe, productive environment and prevents the 5% schedule growth typically caused by poor logistics.

Utilizing Standard Pallet Specs and L-Corners to Minimize On-Site Delays

Reliable material specs are as important as the stone itself. We standardize our packaging and pre-fabricated components so your site managers can plan storage footprints with absolute precision.

- Space Allocation: Use our standard 110cm x 110cm plywood crates to plan predictable storage grids on crowded sites.

- Corner Solutions: Deploy matching L-Corners to eliminate on-site cutting. This reduces dust, noise, and labor bottlenecks at wall transitions.

- Weight Limits: Shipments for urban projects are capped at the 17.5-ton port standard to ensure easier handling and compliance.

- Pre-Shipment Verification: Review high-definition visual reports of your actual batch before it leaves the factory to prevent staging rework or color inconsistencies.

Handling pre-fabricated L-corners instead of field-cutting stone keeps your site cleaner and faster. This integrated approach ensures that the “Big 10” inventory items arrive ready for immediate installation, protecting both your timeline and your margins.

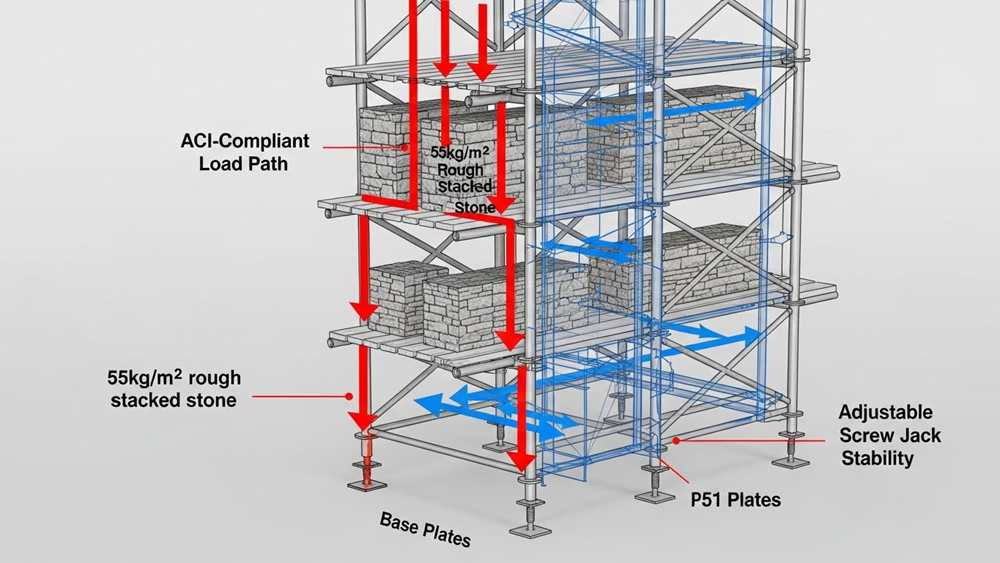

Vertical vs. Horizontal Flow: How to Manage Scaffolding Weight Loads

Direct vertical loads through standards while using horizontal ledgers to prevent sway. Match load paths to material weights, ranging from 30kg/m² for flat panels to 55kg/m² for rough variants.

Load Distribution Mechanisms for Vertical Standards and Horizontal Ledgers

Scaffolding physics relies on a clear division of labor between vertical and horizontal components. Vertical standards function as the primary compression members, funneling the dead weight of the stone directly into the ground. Horizontal elements serve as the structural “glue,” preventing the vertical posts from bowing under pressure or shifting laterally.

- Vertical Standards: Bear 30-60 kN per leg, transferring weight to base plates.

- Horizontal Ledgers: Distribute 10-20 kN of lateral force to maintain stability.

- Transoms: Provide localized support for 10-15 kN.

- Adjustable Screw Jacks: Level the foundation to prevent uneven sinking and point-load stress.

Vertical trusses work with standards to stop buckling when stacking high-density stone at significant heights. Proper spacing between these components ensures the weight doesn’t concentrate in one weak point, which is vital for maintaining structural integrity during multi-week installations.

Weight Capacity Planning for 30-55kg/m² Stone Specifications

Safety protocols require matching scaffolding configurations to the specific weight of the natural stone. Standard flat panels are manageable with typical ledger spacing, but our rough-textured variants add significant mass that changes the math for the site manager.

- Standard Flat Panels: 30-40kg/m² (8-12 lbs/sq.ft) load requirement.

- Rough Stacked Panels: 55kg/m² load requirement.

- CNC Precision: Diamond-blade edges ensure tight fits to eliminate uneven weight distribution.

- Quarry Consistency: Sourcing from the same vein keeps stone density predictable for load calculations.

Rough Stacked panels demand secondary horizontal transoms to support the extra concentrated weight. Because Górny kamień źródłowy uses CNC diamond-blade cutting, the modular pieces interlock without gaps. This precision prevents the “stepped” weight loading that often causes scaffolding decks to tilt or vibrate during the installation of hand-assembled stone.

Premium Stacked Stone for Architectural Excellence

How to Coordinate “Just-In-Time” Deliveries for Crowded Urban Sites?

Managing 2026 urban stone logistics requires 15-minute arrival windows and direct factory-to-site syncing. This eliminates on-site storage while preventing traffic delays and material damage.

Scheduling Arrival Windows for High-Density Sites

Urban construction sites lack the luxury of staging areas. When a delivery truck arrives early, it risks city citations for blocking traffic; when it arrives late, the entire installation crew sits idle. Successful Just-In-Time (JIT) coordination treats the delivery vehicle as a mobile warehouse that must be emptied and cleared immediately.

- 15-Minute Increments: We coordinate truck arrivals in tight windows to prevent a backlog of vehicles on surrounding city streets.

- Immediate Installation: We align subcontractor work phases so teams install stone panels directly from the pallet to the wall, freeing up ground space instantly.

- Metro Monitoring: Our logistics teams track local traffic data and 2026 metro event schedules to adjust ingress and egress routes in real-time.

- Live Tracking: Project managers use live shared documents to track material movement from the truck bed to specific wall locations.

Protective Palletization and Pre-Shipment Verification

Tight urban zones often require rapid, rough offloading using telescopic handlers or small-capacity lifts. Natural stone is vulnerable during these high-speed transitions. Our factory-level packaging ensures crates survive the journey from the quarry to the skyscraper without mid-transit failure.

- Reinforced Packaging: We use 5-ply reinforced export grade cartons and fumigated plywood crates to withstand rapid offloading in dense city hubs.

- Visual Proof: We provide high-definition pre-shipment visual verification videos to confirm order accuracy and quality before any crate leaves the factory.

- Weight Compliance: We strictly adhere to the 17.5-ton USA port standard, ensuring predictable, legal delivery through major metro transportation networks.

- Standardized Dimensions: By selecting our Big 10 inventory models, contractors utilize standardized pallet dimensions (110cm x 110cm) for easier equipment sharing and lift scheduling.

The 3-Crate Mixing Protocol for Aesthetic Color Consistency

Pulling stone from three crates simultaneously blends natural mineral shifts, preventing visual banding and ensuring a uniform architectural finish across large-scale wall installations.

Eliminating Visual Banding Through Sequential Selection

Natural stone carries inherent variations in color and texture. If an installer works through one crate at a time, the wall often develops “bands” of slightly different shades that highlight where one pallet ended and the next began. We solve this by implementing a strict sequence on-site to ensure the final surface looks like a single, cohesive unit rather than a collection of separate shipments.

- Sequential Pulling: Installers pull panels from three separate pallets in a rotating order to scatter mineral variations evenly across the entire elevation.

- Dry-Lay Pre-Selection: Laying panels on the floor before mounting allows the crew to identify darker or lighter pieces and distribute them strategically.

- Joint Camouflage: Randomizing the selection from multiple crates hides transition points between different production pallets, meeting high architectural standards.

Same-Batch Quarry Sourcing and 95% Hue Uniformity

The 3-crate protocol works best when the base material is already highly consistent. As a direct quarry source, Górny kamień źródłowy controls the extraction process to minimize the delta between crates before they reach the job site. This factory-level oversight simplifies the installer’s job and reduces the risk of visual rejection by the architect.

- Single-Vein Extraction: We source stone for each order from the same quarry vein to keep natural color shifts within a tight, predictable range.

- 95% Hue Standard: Factory grading ensures a 95% hue uniformity standard within a single batch, making on-site blending more effective.

- Batch Control: Strict monitoring reduces the risk of “vein-mismatch,” where one crate deviates sharply from the rest of the shipment.

Managing Site Waste Streams Without Delaying Installation

Streamline site logistics with a Site Waste Management Plan (SWMP) and use pre-fabricated interlocking panels and L-corners to eliminate on-site cutting, dust, and scrap buildup.

Implementing Point-of-Generation Separation and Logistics

Site logistics fail when waste removal becomes an afterthought. If scrap material piles up, it creates physical bottlenecks that stop the flow of installation. A proactive approach treats waste as a scheduled material stream that must be moved with the same precision as incoming stone pallets.

- SWMP Integration: Develop the Site Waste Management Plan during the 2026 project planning phase to lock in recycling and storage zones before mobilization.

- Strategic Bin Placement: Position roll-off dumpsters in the “path of least resistance” for the workforce to ensure removal doesn’t compete with active work zones.

- Source Separation: Sort drywall, wood, and concrete streams at the point of generation to avoid re-handling delays and lower total disposal costs.

- Responsive Pickups: Coordinate with waste vendors for removal schedules that align with just-in-time material deliveries to keep the site footprint lean.

Reducing Debris with Precision Z-Shape Panels and L-Corners

The most effective way to manage site waste is to prevent it from being created. Traditional stone masonry often results in 15% or higher scrap rates due to heavy on-site cutting and mitering. Moving to engineered natural stone components shifts the labor—and the debris—back to the factory floor.

- CNC Precision Cutting: Use CNC diamond-blade Z-shape and S-shape panels. These utilize a male-female interlocking system to ensure a tight fit, nearly eliminating the need for field trimming.

- Pre-Fabricated L-Corners: Deploy matching 90-degree corners to stop manual mitering. This removes the massive volume of dust and scrap associated with wall transitions.

- Reinforced Packaging: Top Source Stone uses 5-ply reinforced export grade cartons to protect panels during transit, preventing waste generated by broken or chipped stone.

- Quarry-Vein Consistency: Sourcing from the same quarry vein per order ensures 95% hue uniformity, which prevents the rejection and disposal of “off-color” panels during final assembly.

Często zadawane pytania

How can site managers prevent on-site stone breakage during handling?

Mechanical lifting equipment like slab dollies, suction lifts, or forklift booms removes the risks associated with manual handling. Store panels upright in A-frame racks with padded supports to avoid the pressure of horizontal stacking. Inspect all lifting attachments for rust or wear before every use to prevent mechanical failure.

What is the most effective way to coordinate stone deliveries with tower crane schedules?

Designate a single site manager as the sole point of contact to align truck arrival times with crane availability. Hold daily meetings to review crane load charts and site layout plans. This ensures all incoming 900kg to 1000kg crates remain within safe lifting capacities for the specific radii required on-site.

How do you maintain quality control consistency across multiple masonry sub-crews?

Use standardized digital checklists for every team and implement automated mortar dispensing to remove human error from mix ratios. Real-time monitoring via drones or 3D laser scanning provides the necessary documentation to verify alignment and workmanship across different work zones consistently.

What logistics are required for shipping natural stone to remote island resorts?

Island logistics demand multi-modal transport, typically transferring ocean freight to smaller barges for final delivery. Coordinate early with destination wharves to confirm they have the heavy-duty infrastructure and equipment to move crates weighing up to 1000kg from the water to the site.

Can heavy stone pallets be staged on balconies during 2026 construction projects?

Staging heavy stone on elevated surfaces requires professional structural verification to confirm the balcony can handle the weight. Consult a structural engineer before positioning 900kg crates on balconies to ensure full compliance with building codes and safety standards.

Does Top Source Stone sell directly to end-users or retail customers?

We serve strictly as a B2B manufacturer for dealers, wholesalers, and brand owners. We do not offer retail sales to end-users. This strict policy protects the profit margins and market territory of our professional partners and prevents direct competition with our distributors.

How do you ensure color uniformity across a large commercial installation?

We control consistency by sourcing material from the same quarry vein for every order. To achieve the best aesthetic result on the wall, installers should follow a 3-crate mixing protocol, blending stones from different crates during the layout process to mitigate natural mineral shifts.

Final Thoughts

Poor logistics and inconsistent material sizing drive the 5% schedule growth that erodes project margins. Our CNC diamond-blade precision and same-vein quarry sourcing eliminate on-site cutting and color banding, safeguarding your reputation against installation delays. Choosing standardized 110cm crates and pre-fabricated L-corners ensures your job site stays lean and your labor costs remain predictable.

We protect your market territory by selling exclusively to B2B partners and providing high-definition visual reports before any crate leaves the factory. Request a sample kit of our “Big 10” inventory to verify the 95% hue uniformity and interlocking fitment firsthand. Contact our team to discuss a 300-square-meter trial order or custom private label packaging for your next large-scale project.