Adhering to 18. Wet Area Specs is the primary defense against the bond failures that turn high-end pool projects into expensive warranty liabilities. When standard adhesives dissolve in saturated environments, stone delamination forces contractors to absorb massive remediation costs and reputation damage.

Górny kamień źródłowy secures these installations using CNC diamond-blade precision and non-water-soluble epoxy resins. Our 100% natural quartzite and slate panels exceed architectural standards for high salinity resistance, providing the structural stability required for submerged and high-humidity applications.

High-Risk Zones: Understanding Delamination Near Pools and Sinks

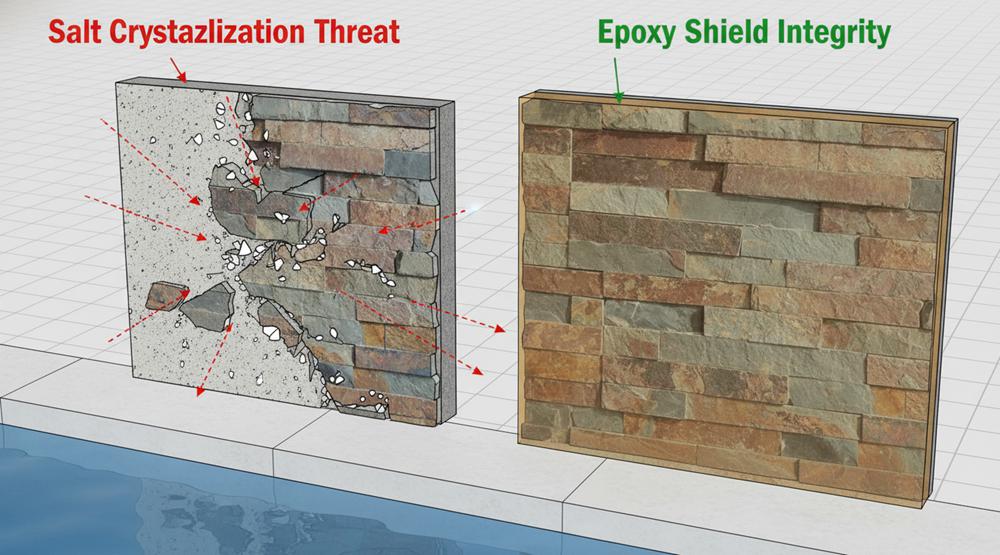

Delamination occurs when moisture or salt weakens the bond between stone and substrate. We prevent failure using non-water-soluble epoxy and precision-cut panels that block water ingress.

Mechanisms of Moisture-Induced Bond Failure

Wet environments create a constant cycle of saturation and evaporation. If an installation uses standard water-soluble adhesives or subpar mortars, these cycles dissolve the bond over time, leading to air voids and eventually “pop-offs.”

- Vapor Pressure: Humidity trapped behind the stone surface creates internal pressure during temperature shifts, forcing the panel to detach from the substrate.

- Salt Crystallization: In saltwater pool environments, salt minerals migrate into stone pores and expand into crystals, physically prying the stone away from the wall.

- Thermal Expansion: Differences in the expansion rates of natural stone and common construction adhesives cause shearing at the bond line during hot-cold cycles.

High-Strength Epoxy Bonding for Humidity Resistance

Top Source Stone addresses these risks during the manufacturing phase. By using specialized chemical bonding agents rather than traditional cementitious backings, we ensure the structural integrity of the panel remains intact even when submerged or exposed to constant spray.

- Epoxy Resin Adhesives: We apply high-strength epoxy formulated specifically for 100% natural stone, creating a bond that is entirely non-water-soluble.

- Controlled Curing: Our panels undergo a temperature and pressure-controlled curing process, ensuring a permanent chemical link between the stone and the reinforcement.

- Salinity Resistance: Materials are tested against high salinity standards to meet 2026 architectural requirements for coastal and poolside projects in the USA and GCC regions.

- CNC Precision: We use diamond-blade edges to ensure a tight interlocking fit, which minimizes the amount of moisture that can penetrate the joints and reach the substrate.

Liquid vs. Sheet Membranes: Selecting the Correct Moisture Barrier

Sheet membranes provide factory-controlled thickness for flat surfaces, while liquid barriers offer a seamless, monolithic seal for complex corners and plumbing penetrations in 2026 stone projects.

Comparing Performance and Application Complexity

Choosing between these two systems depends on the geometry of your installation site. Sheet membranes arrive as pre-formed rolls, ensuring the thickness is consistent before the material even reaches the job site. This is a significant advantage for large, flat surfaces like concrete slabs or balconies.

- Trwałość: Sheet systems offer a 20-year lifespan and provide anti-fracture properties that protect stone from substrate cracking.

- Seam Management: Installation requires meticulous heat-welding or high-strength adhesive sealing at every joint to prevent water bypass.

- Geometry: Liquid membranes excel on vertical walls and irregular surfaces, forming a single layer without joints or weak points.

- Speed: Fluid-applied coatings allow for faster application on large-scale vertical installations common in commercial facades.

High Salinity and Humidity Resistance Standards

Top Source Stone products are frequently specified for coastal regions and high-humidity environments like the Gulf. In these zones, the moisture barrier does more than stop water; it prevents salt and minerals from the substrate from migrating into the 100% natural stone panels.

- Load Bearing: The barrier must support the weight of heavy-duty panels, which reach up to 55kg/m² for our rough-stacked models.

- Salt Protection: Vapor-impermeable barriers are mandatory in high-salinity zones to prevent efflorescence and preserve the hue uniformity of quartzite and slate.

- Material Stability: Pairing our UV-stable natural minerals with a high-performance membrane ensures the architectural finish remains consistent for decades.

Premium Stacked Stone for High-End Projects

Adhesion Science: Why Non-Water-Soluble Mortars are Mandatory

Standard mortars dissolve in constant moisture. Non-water-soluble polymers and epoxy create a hydrophobic barrier, preventing stone panel delamination in pools and high-humidity environments.

| Adhesive Type | Water Resistance | Bond Integrity | Best Use Case |

|---|---|---|---|

| Standard Mortar | Low (Soluble) | Degrades in wet zones | General interior walls |

| Polymer-Modified | High | Resists freeze-thaw cycles | Exterior facades/Sinks |

| Epoxy Resin | Immune | Permanent chemical bond | Submerged pool waterlines |

Capillary Suction and Bond Decay in High-Moisture Zones

Substrate characteristics dictate the ultimate strength of a bond. For non-water-absorbent materials, bond strength drops rapidly as water-to-binder ratios in the mortar increase. This is why standard mixes fail; they cannot manage the hydrostatic pressure in pool or sink zones.

Wetting water-absorbent bases or applying cement-rich pastes reduces capillary suction. This mechanical adjustment is vital for maintaining the 30-40kg/m² load required for standard stacked stone panels. Without it, the weight of the stone eventually pulls the adhesive away from the saturated surface.

Constant moisture in 2026 pool environments triggers delamination through repeated saturation-dry cycles. We solve this by balancing vapor permeability with water repellency. This specific balance stops water ingress while allowing the wall to breathe, which prevents mold growth behind the stone veneer.

Engineered Epoxy Resin and Polymer-Modified Adhesion Specs

Top Source Stone utilizes high-strength epoxy resin adhesives to ensure a permanent bond between individual stone pieces and the panel substrate. This chemical bond is far superior to mechanical holds, especially when panels are exposed to the weight and vibration of commercial plumbing or pool pump systems.

- Mechanical Strength: Polymer-modified mortars provide UV stability and strength for submerged applications.

- Freeze-Thaw Resistance: Non-water-soluble agents prevent ice crystals from forming within the adhesive layer, meeting strict ASTM standards.

- Precision Edges: CNC diamond-blade edges create a tight male-female interlock, minimizing the mortar surface area exposed to water.

- Load Tolerance: Designed to support 8-12 lbs/sq.ft without sagging or creep during the curing phase.

The precision-cut interlocking structure effectively conceals the installation substrate. By reducing the visible vertical joints, we eliminate the primary entry points for water ingress. This engineering ensures that the adhesive layer remains dry and the structural integrity of the wall remains intact over decades of exposure.

How to Prevent Efflorescence in Constant Moisture Environments?

Stop efflorescence by blocking the moisture path with barriers, choosing high-density stone like quartzite, and using precision-cut joints to prevent water from entering the substrate.

Eliminating the Migration Path via Waterproof Barriers and Drainage

Efflorescence requires a migration path. If water cannot travel through the masonry, salts stay trapped inside rather than blooming on the surface. Professionals must focus on isolating the stone from both ground moisture and surface splashing.

- Moisture Barriers: Apply liquid-applied waterproof membranes or vapor barrier sheeting to block ingress from the substrate side.

- Active Drainage: Install weeping tiles and sump pumps to prevent water from accumulating behind the wall system.

- Flashing Details: Position flashing within 10 inches of the grade to redirect water away from the stone veneer.

- Humidity Regulation: Maintain low humidity in indoor pool or spa environments through active ventilation and industrial dehumidification.

Sourcing High-Salinity Resistant Quartzite with Precision-Cut Joints

Material selection determines the long-term success of a project in high-salinity zones. High-porosity stones act as sponges, drawing soluble minerals to the surface as water evaporates. We engineer our ułożony kamień to minimize these entry points through density and mechanical fit.

- Low-Absorption Stones: Utilize materials with high density, such as Alaska Gray Quartzite or Carbon Black Slate, which naturally resist mineral leaching.

- CNC Diamond-Blade Precision: We use CNC edges to create tight interlocking fits. This precision shields the substrate and reduces the exposed mortar area where water typically enters.

- Same-Vein Consistency: Sourcing stone from the same quarry layer ensures uniform mineral content, preventing the “patchy” salt deposits often seen with mixed-source batches.

- Interlocking Engineering: Our Z-Shape and S-Shape panels utilize a male-female connection system to camouflage vertical joints and eliminate visible gaps that trap moisture.

Wholesalers and contractors should prioritize these technical specs during the sourcing phase. Using 100% natural minerals with high salinity resistance ensures the stone maintains its structural integrity without the fading or chalking issues common in lower-grade alternatives.

Joint Sealing and Plumbing Transition Details in Wet Areas

Use ASTM C920 sealants and CNC-cut stone panels to create watertight transitions. L-corners and interlocking Z-shapes minimize gaps around plumbing fixtures for high-moisture durability.

Technical Standards for Movement Joints and Substrate Preparation

Long-term waterproofing in wet environments relies on the ability of the sealant system to handle structural shifts without failing. Selecting the wrong chemistry or ignoring depth ratios leads to delamination and moisture bypass behind the stone veneer.

- Sealant Class: Select elastomeric sealants meeting ASTM C920 Class 25 to handle ±25% movement without delamination.

- Joint Geometry: Configure joints to a 1:1 or 2:1 width-to-depth ratio, maintaining depths between 6.35 mm and 12.7 mm.

- Application Limits: Verify cementitious substrates are fully cured and ambient temperatures exceed 40°F before application.

- Cove Formation: Apply polyurethane sealants continuously to horizontal joints to form a slight cove, preventing debris and water accumulation.

Applying CNC Precision and L-Corners for Seamless Plumbing Transitions

Plumbing penetrations are the most common failure points in wet area masonry. Standard hand-cut stone creates wide, irregular voids that require excessive sealant. Top Source Stone utilizes precision engineering to reduce these tolerances, ensuring the sealant acts as a secondary barrier rather than a primary filler.

- CNC Diamond-Blade Edges: Precision-cut edges create a tight male-female interlock, reducing the sealant volume required at vertical joints.

- Prefabricated L-Corners: Matching 90-degree corners maintain texture synchronization and simplify the sealing of corner voids at wall intersections.

- Z-Shape Interlocking: These panels camouflage the installation substrate and eliminate visible “stepped” gaps around plumbing flanges.

- Material Resistance: Use mildew-resistant, non-staining sealants to complement the high salinity and humidity resistance of natural quartzite or slate.

Często zadawane pytania

Is natural stacked stone recommended for shower walls?

Stacked stone is not a practical choice for shower interiors. The split-face texture creates deep crevices that trap soap scum, hair, and debris, making it nearly impossible to keep hygienic. For wet zones, flat natural stone tiles are a better option because they allow for easy cleaning and efficient water drainage.

How do you prevent mold in the deep crevices of the stone?

Apply a penetrating sealer every 6 to 8 months in high-moisture areas to block the stone’s microscopic pores. Keep room humidity below 50% and use pH-neutral cleaners. Top Source Stone utilizes CNC diamond-blade precision to ensure a tight interlocking fit, which minimizes the gaps where moisture and organic matter can accumulate.

What sealer works best for stone around saltwater pools?

Silane-siloxane water-repellent sealers are the most effective for saltwater environments. They stop salt from penetrating the stone pores while keeping the natural look intact. Before sealing, clean the stone with a heated pressure washer to remove existing salt deposits that could prevent the sealer from adhering properly.

What causes white powdery stains on the stone surface?

This residue is efflorescence. It happens when minerals dissolve in water and travel to the stone surface as the moisture evaporates. This usually indicates that water is getting into the substrate. To stop this, install a moisture barrier behind the stone and seal the surface to block mineral transport.

Can I use stacked stone for a pool waterline?

Travertine stacked stone is a reliable choice for pool waterlines because it stays cool and is naturally slip-resistant. Avoid slate, as it tends to flake when submerged or constantly wet. Keep your pool pH between 7.4 and 7.8; if the water is too acidic, it will etch the stone surface over time.

Final Thoughts

Cheap stone alternatives often fail under the hydrostatic pressure and salinity of modern pool environments, leading to expensive delamination claims. Our CNC diamond-blade precision and non-water-soluble epoxy bonding safeguard your reputation by ensuring structural integrity in high-moisture zones. Investing in same-vein consistency and engineered interlocking panels prevents the patchy, salt-damaged look that plagues lower-grade inventory.

Verify our material density and Z-Shape seamless fit by requesting a sample kit or starting with a 300-square-meter trial order. We offer private label options and pre-shipment visual verification to protect your project margins and brand standards. Contact our team today to secure high-salinity resistant quartzite from our ready-to-ship “Big 10” inventory.