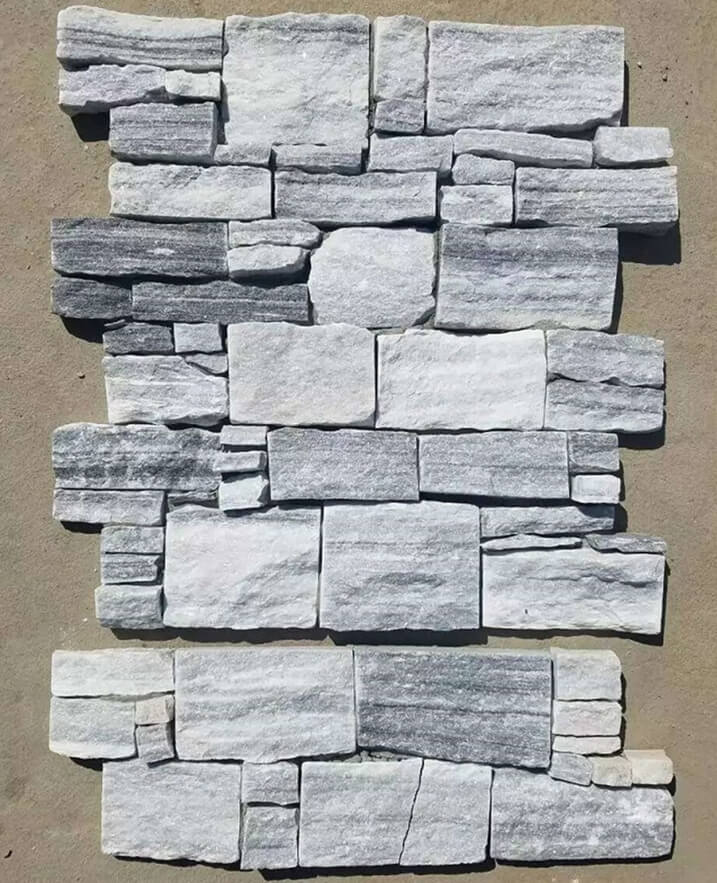

What is the difference between Wholesale Silver Grey Interlocking Natural Stone Ledger Panels and other stone cladding options?

Wholesale Silver Grey Interlocking Natural Stone Ledger Panels features 100% natural quarried stone with authentic cleft finish. Unlike manufactured veneer, every panel is actual stone with genuine mineral content and natural variation. The pre-mounted cement backing simplifies installation compared to full-thickness stone masonry. Traditional full-thickness stone requires specialized rigging and takes longer to install. Our ledgestone gives you the authenticity of natural stone with 40-60% faster installation.

Can Wholesale Silver Grey Interlocking Natural Stone Ledger Panels be used indoors?

Yes. The stone works for interior fireplaces, accent walls, feature areas, and design elements. Indoor applications don’t require waterproof barriers behind the backing, simplifying installation. The natural grey tones complement modern and traditional interiors equally well. Many hospitality and commercial projects use our ledgestone on interior walls specifically for the authentic aesthetic it delivers.

How does water get managed behind the panels?

For exterior installations, a waterproof barrier (cement backer board or membrane) installs before the stone. The barrier directs water down and away from the wall structure. Type S mortar provides secondary water resistance at panel joints. The natural stone is porous, which is normal—water moves through the stone but gets directed away by the waterproof substrate behind the backing. Proper installation technique keeps water from pooling or accumulating in cavities.

Do the panels need sealing?

Sealing is optional. Natural stone panels without sealing perform well in most climates. Invisible penetrating sealers are available if you want enhanced water resistance or easier maintenance. The sealer doesn’t change the stone’s appearance and makes routine cleaning simpler. For high-exposure exterior walls or commercial applications where maintenance access is limited, sealing is recommended.

What mortar type should I use?

Type S mortar is required. This high-strength cement-based mortar withstands the weight, environmental stress, and freeze-thaw cycles that stone cladding experiences. Construction adhesive is not suitable—it can’t hold the weight of stone panels and breaks down under moisture and temperature changes. Always use Type S mortar or Type N mortar for applications where Type S is not available. Follow mortar manufacturer instructions for mixing and application.

How tight should mortar joints be?

Keep joints to 1/2 inch or less. Tight joints look professional and perform better. Wide joints trap water, create visual inconsistency, and reduce structural integrity. Avoid long, straight unbroken joint lines—stagger joints for strength and aesthetics. Use tile spacers to maintain consistent joint width during installation.

How do I handle color variation between boxes?

Wholesale Silver Grey Interlocking Natural Stone Ledger Panels arrives with natural colour batching—each box represents stone from the same quarry production run. Minor shade variations within the Silver Grey specification are normal and expected. Mix panels from multiple boxes during installation for balanced colour distribution across the wall. Work from 20-30 square feet laid out on the ground before setting, allowing you to select and balance colour, texture, and thickness across the entire installation.

What’s the installation timeline?

Experienced crews install 40-50 square feet per day under standard conditions. A 500-square-foot wall typically completes in 10-12 working days. Timeline depends on substrate preparation, weather conditions, and crew experience. Pre-mounted panels eliminate many delays associated with traditional masonry, so projects stay on schedule better than full-stone installations.

Do you offer corner pieces?

Yes. Matching corner pieces integrate with flat panels at inside and outside corners. Corners arrive 300 × 200mm and mount the same way as flat panels. Using corners eliminates awkward stone cuts and creates a professional finished appearance. Corners typically represent 15-20% of material orders depending on your project’s design.

What tools do crews need?

Standard masonry tools work: trowel, level, grout lines, measuring tape, wire brush for surface prep, and an angle grinder or stone saw for occasional cuts at edges or around obstacles. Crews don’t need specialized stone-cutting equipment. Safety equipment includes gloves, dust masks during cutting, and eye protection. No heavy rigging equipment needed.

How much waste should I budget?

Typical waste runs 5-8% with proper installation. This accounts for cuts at edges, corners, and occasional damaged panels. This is significantly lower than traditional masonry waste (15-20%) because the pre-sized panels require minimal fitting. Careful layout planning before installation reduces waste further.

Is the cement backing moisture-proof?

The cement backing is not fully waterproof—it’s water-resistant. For exterior applications, a waterproof membrane installs behind the panels to manage water infiltration. This secondary barrier prevents water from reaching the wall structure. The cement backing itself directs moisture away and works with the mortar joints to minimize water penetration into the wall assembly.

How long do these panels last?

Wholesale Silver Grey Interlocking Natural Stone Ledger Panels lasts 50+ years in standard installations, with many installations lasting 75+ years. Natural stone doesn’t degrade like synthetic materials. The durability depends on proper installation, climate exposure, and maintenance frequency. Cold climates require attention to freeze-thaw protection. Coastal environments benefit from regular maintenance cleaning to manage salt exposure.