Deciding between stacked stone vs faux stone determines whether a commercial renovation stays under budget or collapses under the weight of unforeseen structural reinforcement costs. Project managers often face the trade-off between the authentic appeal of natural masonry and the rapid deployment of high-density polymers. Choosing the wrong material leads to missed deadlines, overextended labor budgets, and potential failure to meet specific load-bearing requirements on interior partitions.

This comparison breaks down the technical specifications of polyurethane panels and natural stone veneers to help you evaluate which material fits specific engineering needs. We examine weight-per-square-foot ratios, the installation mechanics of screws versus mortar, and how these choices affect long-term maintenance in both interior and exterior environments. Use this breakdown as a standard operating procedure for selecting cladding that balances texture with efficient job-site logistics.

Faux vs. Real: What’s the Real-World Difference?

Deciding between faux and natural stone veneer involves a direct trade-off between immediate labor savings and the permanent geological integrity of quarried minerals.

Natural stone veneer utilizes 100% quarried stone, providing unique textures that molded products cannot replicate. This authenticity stems from the fact that each natural stone panel features unique geological characteristics, preventing the “repeating pattern” often seen in faux stone molds. While high-density polyurethane and concrete composites have improved, they rely on chemical pigments and repetitive casting. Real stone provides a depth of texture that creates natural shadows and highlights, which synthetic panels often lack.

Composition and Texture Authenticity

The tactile difference between organic minerals and synthetic composites remains the primary differentiator for high-end projects. When we examine the mineral composition, natural stone offers a variation in density and light reflection that chemical pigments simply cannot simulate.

- Each natural stone panel features unique geological characteristics, preventing the visual fatigue of repeating patterns found in manufactured sets.

- Natural stone offers the authentic feel of real minerals, whereas faux stone consists of concrete composites and chemical pigments.

- Real stone provides a depth of texture that creates natural shadows and highlights, which synthetic panels usually lack.

Color Stability and Weather Resistance

Natural stone remains UV-stable and maintains its original appearance for decades, even in harsh 2026 climates. Because the color exists throughout the entire stone rather than just on the surface, these materials do not fade or peel when exposed to direct sunlight over many years. In contrast, many faux stone products use surface dyes that can degrade or wash out, eventually requiring touch-ups or full replacement.

- Natural stone colors are permanent and resist the bleaching effects of intense UV exposure.

- The inherent durability of natural materials ensures the stone resists weathering, moisture, and temperature fluctuations without losing its structural integrity.

- Faux stone surface dyes can degrade, often revealing the underlying gray concrete if the panel is chipped or worn.

Weight and Structural Load Requirements

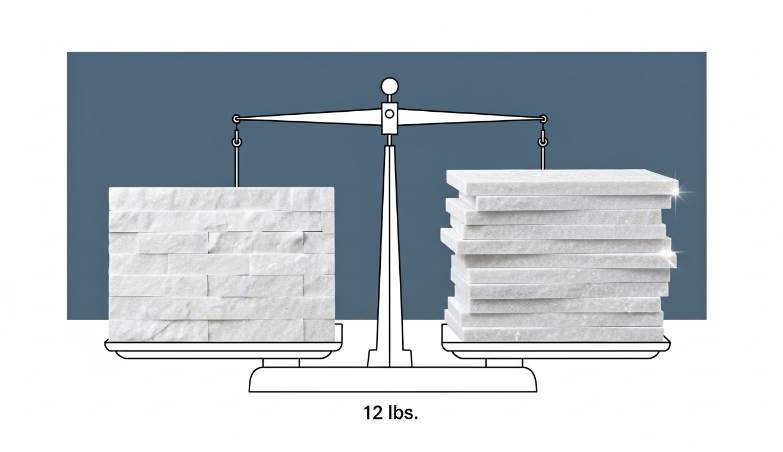

Both modern faux and natural stone veneers focus on lightweight profiles to simplify the installation process. We see natural stacked stone panels typically weighing between 8 and 13 lbs per square foot, which makes them suitable for most existing walls without the need for additional structural reinforcement.

- Thin-cut natural stone panels do not require the expensive concrete footings or wall ties needed for full-thickness stone blocks.

- Lightweight profiles allow for faster installation on various surfaces, including cement board, brick, and concrete.

- The reduced weight of both material types lowers shipping costs and labor fatigue during large-scale deployments.

Market Appreciation and Asset Value

Real stone is recognized as a premium building material that offers a higher return on investment than synthetic alternatives. Homebuyers and commercial developers perceive real stone as a high-value upgrade, which can directly increase property resale prices. While faux stone offers a lower initial price point, real stone serves as a permanent architectural feature that lasts a lifetime. Using authentic materials reflects a commitment to quality and craftsmanship, enhancing the professional reputation of contractors and designers alike.

What is Faux Stone? (Polyurethane) (Pros, Cons, Best For)

High-density polyurethane panels provide an engineered alternative to traditional masonry, offering significant thermal insulation and moisture resistance without the structural weight of quarried stone.

Characteristics of High-Density Polyurethane Panels

Manufacturing in 2026 utilizes high-pressure molding techniques to replicate the visual depth of natural stone with extreme precision. These panels capture the organic textures of slate, limestone, and fieldstone by using molds taken from actual quarried pieces. Because the material consists of closed-cell polyurethane, it serves as a functional component of the building envelope, providing inherent moisture resistance that prevents water absorption into the substrate.

- Integrated insulation properties improve the R-value of the wall, helping to mitigate thermal bridging in both residential and commercial structures.

- Advanced surface treatments ensure that panels meet current architectural sustainability standards while maintaining color consistency across large production runs.

- The lightweight composition allows for oversized panels that cover more surface area per unit than individual thin veneers.

Advantages of Synthetic Stone Solutions

Faux stone offers clear logistical advantages by removing the need for specialized masonry infrastructure. You can install these panels directly onto standard drywall or plywood sheathing using screws and construction adhesive, bypassing the requirement for structural footings or masonry ties. This approach reduces the dead load on the building, which is critical for retrofitting older structures that cannot support the weight of real stone.

Labor efficiency drives the adoption of these systems. Projects that would take weeks for a skilled mason can be finished in days by general carpenters or even capable DIYers. By eliminating the wet-work associated with mortar and grout, site cleanliness remains high, and project timelines stay predictable regardless of weather conditions that might otherwise halt traditional stone application.

Performance Limitations and Material Trade-offs

While synthetic panels are highly versatile, they have specific thermal and aesthetic limitations. Polyurethane is sensitive to extreme heat; it cannot be used as an immediate firebox surround or in direct contact with high-output heat sources without maintaining specific clearances defined by local fire codes. Over decades, synthetic panels may also lack the natural weathering and “patina” that genuine stone develops, making them less suitable for heritage-grade restorations.

- Installers must vary panel placement carefully to prevent repeating visual patterns on expansive walls.

- Impact resistance is lower than natural stone; a sharp blow can dent the polyurethane surface and expose the underlying foam core.

- UV exposure in harsh climates can cause pigment fading over an 8-to-10-year window if the product lacks high-grade UV stabilizers.

Optimal Applications for Faux Stone

Faux stone excels in interior environments where the goal is a rapid aesthetic transformation. Residential interior accent walls, basement renovations, and fireplace surrounds (with proper clearances) are prime candidates because they provide the look of heavy masonry without the mess of mortar. The material’s portability also makes it the standard choice for temporary commercial displays and retail build-outs where speed and ease of removal are prioritized.

For exterior use, these panels are best suited for non-coastal residential siding and decorative skirting. They allow homeowners to achieve a “stacked stone” look on a budget while benefiting from the added insulation layer. Because the installation requires only basic carpentry tools, it remains the most viable path for DIY home improvements seeking to increase curb appeal without professional masonry costs.

Authentic Natural Beauty Meets Efficient Installation

What is Real Stone Veneer? (Natural Stone) (Pros, Cons, Best For)

Natural stone veneer provides an uncompromising geological profile and decades of UV resistance that manufactured alternatives cannot match, though it requires a higher threshold for structural load and installation skill.

Authentic Quarry Origins and Composition

Natural stone veneer features thin layers sliced directly from genuine quarried blocks or collected fieldstone. This process preserves the raw geological integrity of the source material, ensuring that every panel reflects the unique environment where it formed over millennia.

- Manufacturers extract granite, slate, quartzite, and marble from active quarries to ensure material consistency.

- Precision cutting with diamond-tipped saws produces pieces ranging from 0.75 to 1.5 inches thick.

- Each panel retains mineral veins and organic textures that factory molding processes fail to replicate.

- Current 2026 production standards utilize high-strength epoxy resin adhesives to bond natural pieces into interlocking Z-shaped panels.

Unmatched Durability and Aesthetic Longevity

The primary appeal of real stone centers on its ability to withstand environmental stressors while increasing the tangible value of a property. Unlike synthetic options, natural stone resists weathering through its inherent density and mineral composition.

- Natural stone resists UV damage, keeping colors vibrant without fading after decades of sun exposure.

- The material handles harsh exterior climates and high-moisture interior zones with ease.

- Homeowners choose real stone for its status as a lifetime material that typically outlasts the building’s other decorative elements.

- Real stone adds actual asset value to the structure, avoiding the replacement cycles common with synthetic alternatives.

Weight, Cost, and Installation Complexity

Real stone veneer presents specific logistical challenges that contractors must account for during the planning phase. The weight and labor requirements dictate a more intensive installation schedule compared to foam or plastic-based products.

- Standard panels weigh between 8 and 13 pounds per square foot, significantly more than polyurethane options.

- Installation requires skilled labor to manage mortar or specialized adhesives, increasing the total project budget.

- Intensive quarrying and transportation processes keep material costs higher than manufactured stone.

- Thin veneer requires a structurally sound substrate like cement board or masonry to support the load.

Optimal Applications for Modern Projects

Architects and designers select real stone veneer for high-impact areas where authenticity and fire safety remain paramount. Its thermal properties and physical texture make it the standard for premium builds.

- Real stone is non-combustible, providing the safest choice for fireplace surrounds and chimney stacks.

- It excels in high-end commercial facades and residential accent walls where visitors view the texture at close range.

- Landscaping projects like retaining walls and outdoor kitchens benefit from the stone’s natural environmental integration.

- Interlocking Z-shape panel systems allow for professional finishes on large-scale interior lobby walls.

The Stone Guru’s Showdown: Realism, Cost, and Weight

Selecting between natural stone and high-density faux panels requires balancing the immediate labor savings of lightweight synthetics against the multi-generational durability and resale value of real quarried minerals.

Visual Authenticity and Texture Variance

Natural stone veneer provides a level of aesthetic depth that synthetic manufacturing cannot fully mirror. Because these panels utilize genuine quarried material, no two sections share identical color gradients or surface characteristics. This organic variance prevents the “stamped” look often associated with mass-produced alternatives. In 2026, natural stone remains the standard for projects where close-range inspection occurs, such as interior accent walls or entryway pillars, because it lacks the repeating patterns found in molded products.

Faux alternatives, typically made from polyurethane or reinforced concrete, rely on a finite set of molds. While high-end panels replicate the feel of stone, large exterior facades often reveal noticeable pattern repetition if the installer does not carefully randomize the layout. Furthermore, natural stone maintains its color integrity under harsh UV exposure. Pigmented concrete and polyurethane products face a higher risk of fading or surface degradation over a decade of direct sunlight, whereas real minerals remain colorfast for the life of the structure.

| Performance Metric | Natural Stone Veneer | Faux Stone Panels |

|---|---|---|

| Avg. Material Cost | $10 – $20 per sq. ft. | $5 – $10 per sq. ft. |

| Weight Load | 8 – 13 lbs per sq. ft. | 1 – 3 lbs per sq. ft. |

| Lifespan (Exterior) | 50+ Years | 8 – 20 Years |

| UV Resistance | Excellent (Permanent) | Moderate (Fading possible) |

Initial Investment versus Long-Term Property Value

Price points create a clear divide between these two categories. Faux stone panels offer an accessible entry point for DIY interior projects, typically costing between $5 and $10 per square foot. This lower price reflects the reduced shipping costs and the lack of specialized masonry skills required for installation. For temporary cosmetic upgrades or short-term house flipping, faux panels provide an immediate visual boost without a heavy capital outlay.

Natural stacked stone veneer commands a higher price, averaging $10 to $20 per square foot, but functions as a permanent asset. Property appraisals favor natural materials due to their 50-year lifespan and resistance to impact damage. While both systems now utilize interlocking designs to speed up installation, the long-term ROI of natural stone remains superior for permanent residences. You avoid the replacement cycle often seen with manufactured materials, which may require a refresh every 8 to 10 years in harsh climates.

Weight Specs and Structural Requirements

Modern engineering has reduced the weight of natural stone panels, making them competitive for many residential retrofits. Stacked stone panels usually weigh between 8 and 13 lbs per square foot. Most standard walls support this weight without requiring additional footings, though installers should verify the integrity of the substrate. We recommend using a cement board substrate rather than standard drywall for real stone applications to ensure the adhesive bond survives moisture and temperature cycles.

Polyurethane faux panels remain the featherweight champion of the industry. Their extremely low weight allows for installation on thin drywall surfaces where any structural reinforcement is impossible. This makes them ideal for ceiling accents or upper-story remodels where weight limits are a concern. While faux panels offer unmatched installation speed, natural stone provides a structural “heft” and tactile coolness that synthetic materials cannot emulate.

Installation Pro Tip: Screws vs. Mortar

Screw-based systems reduce labor timelines by nearly 60% for interior projects, while traditional mortar remains the non-negotiable standard for heavy natural stone exterior facades.

Mechanical Fasteners for Lightweight Systems

Screw-based installation is the primary method for high-density polyurethane and lightweight panels in 2026. This “dry-run” technique eliminates the mess and prep time associated with wet masonry, making it the preferred choice for interior feature walls. Because these panels feature integrated nailing flanges, you can secure them directly to wall studs or solid sheathing. This method allows for immediate weight-bearing, so you can finish a 100-square-foot accent wall in a single afternoon without waiting for adhesives to cure.

| Performance Metric | Screw-Based (Faux) | Mortar-Based (Real Stone) |

|---|---|---|

| Installation Speed | 40-60% Faster | Labor Intensive |

| Curing Time | None (Immediate) | 24 – 48 Hours |

| Skill Required | Basic Carpentry | Professional Masonry |

| Clean-up Level | Minimal (Dust Only) | High (Wet Mix/Grout) |

Mortar Application for Natural Stone Panels

Natural stacked stone panels carry significantly more mass, often weighing between 8 and 13 lbs per square foot. This weight requires a permanent chemical and physical bond that only high-strength mortar or specialized stone epoxy can provide. Professional installers use the “back-buttering” technique to ensure 100% coverage, which prevents air pockets where moisture could collect.

- Thin-set mortar formulated for natural stone prevents sag during the vertical application.

- Mortar acts as a structural stabilizer, filling gaps in the substrate for a seamless look.

- Interlocking Z-shaped panels hide mortar lines, creating a monolithic appearance without visible grout.

- This method is the benchmark for exterior facades where freeze-thaw cycles and high winds test the cladding’s integrity.

Substrate Requirements and Preparation

The success of your installation depends on what lies behind the stone. Mortar requires a clean, porous surface like cement backer board, brick, or concrete to bite into. If you plan to install real stone over interior drywall, we recommend adding a layer of cement board first to handle the vertical load. Screw-based systems are more forgiving but still require a flat, solid surface. For any exterior application, always install a moisture barrier and proper flashing before the stone goes up, whether you are using mechanical fasteners or traditional wet-laid techniques.

متانة & Location: Interior vs. Exterior

Environment dictates the material choice: natural stone offers unmatched UV and weathering resistance for exteriors, while faux panels provide lightweight versatility and fire-rated safety for complex interior applications.

The durability profile of الكسوة الحجرية solutions varies significantly based on the application environment. While interior installations allow for more flexibility, exterior surfaces face constant environmental stress that quickly separates high-performance materials from budget-grade synthetic alternatives. Natural stone maintains its physical integrity under harsh cycles, whereas many manufactured products rely on surface-level aesthetics that can degrade when exposed to the elements.

Weathering and UV Resistance

Natural stone maintains its physical properties and appearance even when exposed to harsh environmental cycles and direct sunlight. In exterior settings, UV exposure acts as a primary catalyst for material failure in synthetic products, leading to pigment breakdown and structural embrittlement. Real stone remains immune to these effects because its color is geological rather than chemical.

- Natural stone panels withstand UV exposure without fading, unlike faux products that rely on surface pigments.

- High-strength epoxy resin used in 2026 manufacturing ensures stone pieces remain bonded despite extreme temperature shifts.

- Exterior installations benefit from the inherent density of real stone, which resists surface degradation and erosion over decades.

Interior Performance and Safety

Indoor environments allow for diverse design applications where stone adds long-term value and meets safety standards. Natural stone panels provide a level of fire resistance and textural depth that synthetic alternatives cannot match, especially in high-visibility areas where guests or clients view the material at close range.

- Natural stone panels are non-combustible, making them a preferred choice for fireplace surrounds and kitchen backsplashes.

- Interior feature walls in 2026 residential and commercial projects provide unique textures that faux materials cannot replicate.

- The lightweight panel system allows for installation on standard interior walls without the need for structural footings.

Moisture Management and Sealing

Proper installation techniques and maintenance products protect the stone and the underlying structure from water-related issues. For both interior and exterior projects, managing the substrate and the interface between panels prevents the migration of moisture into the wall cavity, which is the most common cause of stone failure.

- Exterior stone applications require a dedicated moisture barrier and flashing system because panel joints are not naturally waterproof.

- Applying a high-quality pH-neutral sealer after installation prevents staining and simplifies routine cleaning in high-traffic areas.

- Natural stone remains stable in humid environments, though builders must ensure the substrate is properly prepared with cement board.

Color Permanence and Longevity

Real stone provides a permanent aesthetic solution that retains its original character throughout the life of the building. Because the material is uniform throughout its thickness, it avoids the “painted concrete” look that occurs when manufactured stone sustains impact damage or surface wear.

- The color in natural stone exists throughout the material, so minor chips or scratches do not reveal a different core color.

- Faux stone products often show wear as their painted surfaces erode, while real stone panels develop a natural patina over time.

- Using real stone in 2026 construction increases property value by providing a durable, high-end finish that requires minimal replacement.

The Final Verdict: Which One Should You Actually Buy?

The choice between natural and faux stone hinges on a single question: are you building for the next decade or the next half-century?

Select Natural Stacked Stone for Long-Term Property Value

Natural stone remains the industry benchmark for any project requiring a 50-year lifecycle and authentic aesthetic appeal. We recommend natural panels for exterior facades and high-visibility areas. Synthetic alternatives often show significant fading or pigment degradation within ten years of consistent UV exposure. In 2026, 100% quarried stone continues to drive higher asset value and a superior return on investment compared to concrete or polyurethane composites.

| Performance Metric | الحجر الطبيعي المكدس | Faux Stone (Polyurethane) |

|---|---|---|

| Estimated Lifespan | 50 – 100+ Years | 10 – 25 Years |

| Installation Method | Mortar or Z-Panel System | Screws and Adhesive |

| Weight per Sq. Ft. | 8 – 13 lbs | 1 – 2 lbs |

| UV & Heat Resistance | Excellent / Non-combustible | Moderate / Fades Over Time |

- Use natural stone for fireplace surrounds; its non-combustible nature ensures safety near open flames.

- Focus on quarried materials for high-traffic commercial zones where impact resistance is mandatory.

- Apply high-quality sealants post-installation to maintain the stone’s integrity in wet environments.

Use Faux Alternatives for Temporary or Weight-Restricted Interiors

Faux stone serves specific niche applications where structural capacity is limited. Use these panels when working on non-load-bearing interior partitions that cannot support the weight of natural stone. While the initial costs sit 20-30% lower than natural options, the lack of impact resistance makes them vulnerable in high-traffic zones. These manufactured options work best for residential DIY projects where the intended lifespan is less than a decade.

Match Material Choice to Installation Expertise and Environment

Climatic conditions should dictate your material selection. Natural stone panels excel in coastal or harsh environments because they resist salt spray and freeze-thaw cycles better than painted manufactured products. We utilize interlocking Z-shape natural stone systems to achieve a professional, seamless look. This method eliminates the visible grout lines often seen in cheaper faux versions and provides a more durable finish against moisture infiltration.

Professional Recommendation for Contractors and Distributors

Professionals building a reputation for quality should partner with direct manufacturers who control the process from quarrying to packaging. This control ensures color consistency across large-scale developments. Recommending natural stone helps you avoid future warranty claims related to peeling, chipping, or thermal expansion—all common issues with synthetic products. To streamline the job site, use L-shaped corner pieces. These components reduce labor costs and eliminate the need for complex miter cuts during installation.

Conclusion

Choosing between faux panels and real stone veneer depends on your installation preference and the specific requirements of your project site. Faux stone provides a fast, screw-on alternative for interior accents, while natural stone veneer delivers the authentic texture and weather resistance needed for exterior facades. Selecting the right material for your skill level and environment ensures the finish remains secure and visually appealing for years.

Evaluate your wall surface and available tools to determine if a panel system or traditional mortar fits your needs. You can browse our full stone inventory to compare styles and find the best match for your home renovation.

أسئلة مكررة

Which one looks more realistic, faux or real stone veneer?

Real stone veneer remains the most realistic option because it contains the natural mineral variations, unique textures, and organic depth that manufactured products attempt to replicate. However, recent innovations in polyurethane and cast-concrete technology have significantly narrowed this aesthetic gap. High-quality faux stone panels are now virtually indistinguishable from natural stone to the untrained eye, especially when viewed from a standard distance.

Which is cheaper?

Faux stone is the more cost-effective choice when looking at the total project budget. While the material price for high-end manufactured stone has become comparable to natural stone veneer, the overall costs are lower due to lighter shipping weights and significantly reduced labor expenses. Faux stone does not require the expensive structural reinforcements or specialized masonry skills often needed for real stone installations.

Is faux stone easier to install?

Yes, faux stone is substantially easier to install. Because it is lightweight and often sold in interlocking panels, it can be installed using standard woodworking tools and basic fasteners. This eliminates the need for mortar, wet saws, and heavy-duty structural supports, making it an ideal choice for DIY projects and rapid commercial turnarounds compared to the labor-intensive masonry work required for real stone.

Can you use faux stone panels on a fireplace?

Yes, faux stone panels are frequently used on fireplaces, but the specific material matters. Cast-concrete manufactured stone is highly heat-resistant and suitable for most fireplace facings. If using polyurethane or fiberglass panels, they are excellent for decorative surrounds and electric fireplaces, though they must be installed in accordance with local building codes regarding minimum clearance from the firebox opening to ensure safety.

How long does faux stone last?

Faux stone is engineered for durability and typically lasts between 20 and 50 years depending on the environment and material quality. While natural stone provides superior long-term permanence and resistance to fading over many decades, modern faux stone panels are treated with UV inhibitors and weather-resistant coatings to maintain their structural integrity and appearance for the duration of most residential and commercial lifecycles.