Frequently Asked Questions

Q: What adhesive and substrate are required for exterior walls?

For all exterior applications, we specify a high-performance, polymer-modified thinset mortar. The substrate must be a stable, clean masonry or cement board surface over a properly installed weather-resistant barrier (WRB) and metal lath. Direct adhesion to drywall or plywood outdoors is not recommended as it can lead to moisture issues and installation failure.

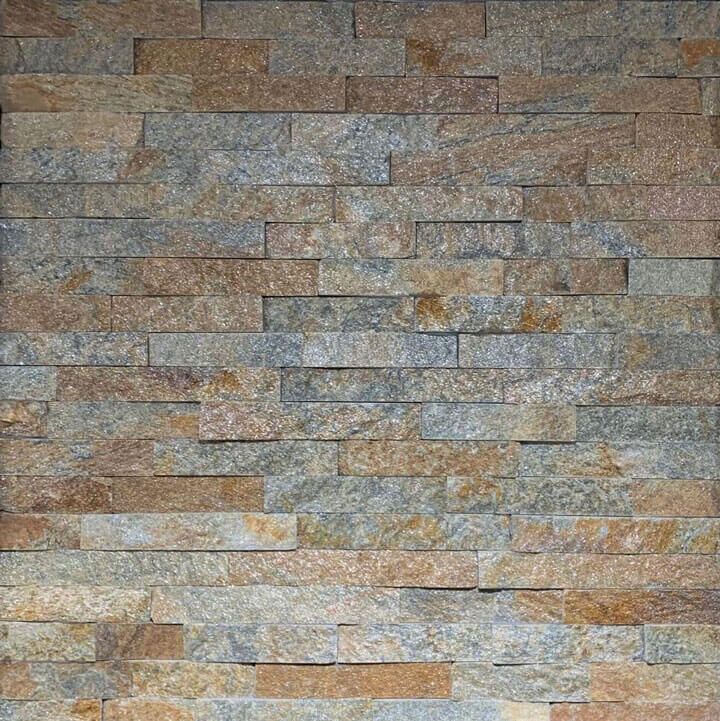

Q: Can Amber Falls panels handle freeze-thaw conditions?

Yes. Natural quartzite has a very low water absorption rate, giving it excellent freeze-thaw resistance. When installed according to industry standards with proper sealing and drainage planes, these panels are suitable for the most demanding cold climates in North America and Europe, ensuring long-term durability.

Q: What type of sealer is best for outdoor Amber Falls installations?

We recommend a high-quality, clear, penetrating (impregnating) sealer specifically rated for natural quartzite. For exterior applications, reapplication every 12-24 months is advised to maintain optimal protection against moisture and staining, thereby preserving the stone’s integrity and appearance.

Q: What is the procedure for handling shipping damage?

Our multi-layer export packaging is designed to minimize shipping damage. However, we recommend inspecting all cartons upon delivery. For minor chips common with natural stone, a color-matched epoxy can be used. In the rare event of significant damage, please document with photos and contact your sales representative within 48 hours of receipt. We will prioritize a replacement shipment to keep your project on schedule.

Q: How much overage (extra material) should I order for a project?

We recommend ordering a minimum of 10-15% overage. This industry standard accounts for material needed for cuts, layout adjustments, and managing the natural color variations within the stone. Ordering sufficient overage from the same production batch is critical for ensuring a perfect color match throughout the project.

Q: Are the pre-fabricated corner pieces necessary for installation?

While not strictly mandatory, the matching 6″×18″ L-corners are highly recommended for a professional and efficient installation. They are factory-made to match the panel texture and color, eliminating difficult and time-consuming miter cuts on-site. This saves significant labor costs and ensures a crisp, seamless look on all outside corners.

Q: Can we mix Amber Falls with other stone panels in one container?

Yes, this is a core part of our B2B logistics service. Our mixed-item container program allows you to blend Amber Falls panels with any of our other quartzite or stone products. This enables you to maintain a diverse inventory, reduce capital risk, and better serve your local market’s needs.

Q: How should our installers cut panels for outlets and fixtures?

For straight cuts, use a diamond-blade wet saw for a clean edge and to control dust. For notches or circular cuts around fixtures, a hand grinder with a diamond cup wheel is effective. We strongly advise adhering to all local safety regulations, including wearing proper PPE and using dust suppression methods.