What substrates work for installing black slate Z panels?

These panels are suitable for installation on concrete block, brick, poured concrete, and fiber cement board substrates. All surfaces must be clean, dry, level, and structurally sound. Maximum substrate variations should not exceed 2 mm over 1200 mm spans. Painted or plastered walls require appropriate surface preparation to ensure proper adhesive bonding.

How much adhesive mortar is needed per square meter?

Plan for 4-6 kg of polymer-modified mortar per square meter of panel coverage. ARDEX X7, ARDEX 77, or Laticrete modified thinset mortars meet the necessary bonding requirements. For full coverage, apply mortar to both the wall and the panel backs.

Can these panels be used for exterior applications in cold climates?

Yes, black slate is highly resilient to freeze-thaw cycles and temperature extremes, from -40°C to +60°C. Its low water absorption rate, below 0.4%, effectively prevents frost damage and cracking. Proper installation with weather-resistant barriers will further protect the substrate materials.

What is the expected service life of black slate cladding?

With proper installation and minimal maintenance, black slate cladding can last 50-100+ years. The material is naturally resistant to fading, weathering, biological growth, and UV degradation. Natural slate roofs have a documented service life exceeding 130 years.

How do I calculate quantities for my project?

Measure the total wall area in square meters and add 10-15% for cuts, corners, and breakage. Each carton covers 0.44 m², and each pallet covers 21.12 m². Corner pieces require a separate calculation, typically approximating 15% of the perimeter length.

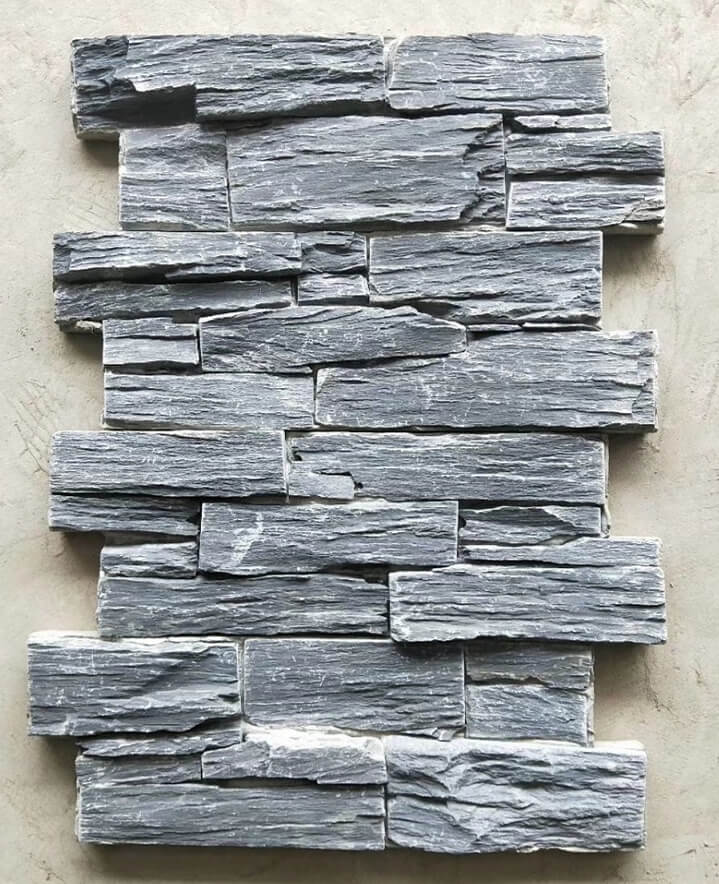

Are these panels suitable for interior feature walls?

Absolutely. Black slate panels are ideal for interior accent walls, fireplace surrounds, bathroom features, and commercial lobby walls. The material offers natural elegance, is easy to clean, and provides excellent moisture resistance.

What maintenance do these panels require?

Black slate cladding requires minimal maintenance, typically just occasional washing with water. The material naturally resists staining, mold, and algae growth. No sealing or recoating is required for exterior applications.

Can I install these panels on curved walls?

Due to the rigid cement backing, flexibility for tight radius curves is limited. Gentle curves can be achieved by cutting panels into smaller sections and carefully adjusting joint gaps. For specific radius requirements, please contact our technical support.

What fire rating do these panels have?

Natural slate is non-combustible and inherently fire-resistant. The cement backing also contributes to fire resistance. Please consult local building codes for specific fire rating certifications required in your jurisdiction.

Do you offer samples for design approval?

Yes, sample panels are available for architects and contractors to evaluate color, texture, and quality before placing full project orders. Please contact our sales representatives for sample requests.