Specifying materials for Commercial Interiors often fails when natural color shifts create a patchy, disjointed appearance across large-scale feature walls. For business owners and architects, these visual inconsistencies represent a direct risk to property value and guest perception.

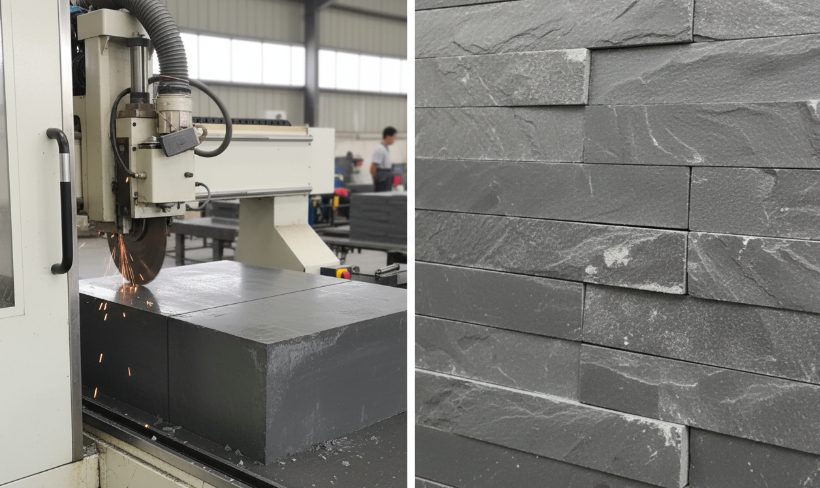

Achieving architectural cohesion requires same-batch quarry sourcing and 95% hue uniformity to eliminate site-specific errors. The 3.5cm Rough Series and CNC diamond-blade interlocking systems provide the specific ASTM fire and acoustic ratings required for high-occupancy retail and hospitality environments.

First Impressions: Why Luxury Hotels Specify Natural Stacked Stone

Natural stone signals exclusivity through unique textures, supporting premium pricing and property value in ways mass-produced alternatives cannot replicate.

Defining Guest Perception Through Geological Authenticity

Hotel lobbies serve as the primary touchpoint for guest experience. Designers select natural stacked stone to remove the “artificial” feel typical of mass-produced materials. Every panel provides a one-of-a-kind appearance because geological patterns never repeat, ensuring grand lobbies feel bespoke rather than manufactured.

- Unique Textures: Natural minerals like Quartzite and Slate provide a tactile richness that reinforces a property’s narrative of permanence and prestige.

- Visual Depth: Organic color variance and grain patterns signal genuine quality that high-end travelers recognize and value.

- Brand Positioning: Authentic materials allow operators to justify premium room rates and distinguish themselves from mid-market competitors.

Achieving Visual Uniformity via Same-Batch Quarry Consistency

Large-scale hospitality projects require tight control over color shifts to maintain architectural integrity. Top Source Stone sources materials from the same quarry vein per order. This protocol ensures 95% hue uniformity across expansive feature walls, avoiding the disjointed or patchy appearance common with mixed-source commercial stone.

- Consistency Standards: We maintain 95% hue uniformity by extracting panels from the same geological layer for each specific project batch.

- Engineering Precision: CNC diamond-blade edges allow modular Z-shape or S-shape panels to fit tightly without visible “stepped” gaps.

- Interlocking Integration: Precision-cut male-female connection systems camouflage vertical joints, creating a seamless look on long corridor walls and exterior facades.

- L-Corner Solutions: Pre-fabricated 90-degree corners ensure texture and color synchronization at all wall transitions, reducing on-site labor.

Durability in Public Spaces: Impact Resistance and Wear-and-Tear

High-traffic environments require dense, mineral-rich surfaces. Top Source Stone’s natural quartzite and slate offer inherent UV stability and impact resistance to survive heavy commercial use through 2026.

Surface Resilience in High-Contact Public Zones

Public infrastructure subjects materials to constant physical stress that would degrade synthetic alternatives. In transit hubs and lobbies, wall surfaces must withstand mechanical energy from rolling luggage, service trolleys, and shifting furniture without denting or cracking. Natural stacked stone functions as a structural shield, maintaining its face under repeat contact.

- Mechanical Impact: Resistance against heavy trolleys and luggage in high-occupancy transit zones.

- Chemical Exposure: Tolerance for high-frequency sanitization cycles and aggressive industrial cleaning agents.

- Environmental Defense: Prevention of surface erosion and abrasion in outdoor plazas and exposed municipal areas.

ASTM Standards and 3.5cm Structural Thickness

We engineer our panels to meet rigorous commercial standards, prioritizing density over lightweight convenience. While thin veneers often fail under pressure, our 3.5cm Rough Series provides the mass required for superior impact absorption. This thickness ensures the stone does not just look authentic but performs as a permanent architectural element.

- Hardness: Use of 100% natural quartzite and slate to provide maximum scratch resistance on the Mohs scale.

- Profile Depth: Implementation of 3.5cm Rough Series panels to increase energy dissipation during physical impacts.

- Climate Stability: ASTM-standard freeze-thaw resistance to prevent delamination or cracking during 2026 extreme weather cycles.

Unlike manufactured “PU stone” or thin ceramic tiles, natural stone maintains its structural integrity and color even when chipped. Because the material is consistent through its entire depth, minor wear patterns blend into the natural texture rather than revealing a synthetic core, protecting the property’s visual standard for decades.

Premium Stacked Stone for Architectural Needs

Using Stone to Diffuse Noise in Busy Restaurants and Cafes

Natural stacked stone breaks up sound waves via irregular textures, reducing the “cocktail party effect” by diffusing echoes in high-traffic commercial dining environments.

Acoustic Diffusion via Natural Cleft Surfaces

Hard, flat surfaces like glass, polished tile, and smooth concrete act as acoustic mirrors. They reflect sound waves directly back into the dining area, which increases reverberation. This buildup of noise creates the “cocktail party effect,” where ambient chatter forces guests to speak louder, further raising the decibel level. Designers often struggle to manage this without resorting to soft fabric baffles that may not align with a premium aesthetic.

Natural cleft and split-face stone finishes solve this by providing a multi-angled surface. When sound waves hit these irregular planes, the energy scatters in different directions rather than bouncing back in a concentrated path. This diffusion helps soften the acoustic environment. Using textured stone walls allows you to create specific “acoustic zones” in high-traffic cafes, maintaining a sophisticated look while naturally dampening the room’s energy.

Strategic Depth and the Rough Series Profile

Standard thin veneers often lack the surface area required to impact room acoustics significantly. Effective sound management requires physical depth and density. The Top Source Stone Rough Series utilizes high-dimensional profiles to disrupt sound wave synchronization across large open-plan restaurants. Using 100% natural minerals provides the necessary mass to anchor sound that would otherwise reflect off lightweight materials.

- Surface Depth: Features thicknesses between 1 inch and 1.75 inches (Rough Series) to maximize sound-scattering surface area.

- Material Density: Natural Quartzite and Slate panels (approx. 55kg/m²) provide high-mass acoustic anchoring.

- Modular Interlock: Z-shape panels use a male-female connection system to create a continuous textured plane without visible vertical joints.

- Joint Precision: CNC diamond-blade edges ensure tight interlocking, preventing sound from leaking into the hollows behind the substrate.

By varying the stone thickness within a single interlocking panel, you create a wall that is geologically unique and acoustically functional. This setup eliminates the repeating patterns found in manufactured faux stone, which often has a more uniform, and therefore more reflective, surface. For commercial interiors, this transition from flat to high-dimensional surfaces is a practical way to balance luxury design with occupant comfort.

Complying with Commercial Fire Safety and Building Codes

Commercial building codes mandate non-combustible materials for high-occupancy safety. Top Source Stone’s 100% natural mineral panels meet IBC standards, providing fire-resistive surfaces without toxic emissions or fuel contribution.

Understanding IBC and IFC Non-Combustible Requirements

The 2026 International Building Code (IBC) and International Fire Code (IFC) prioritize materials with Class A fire ratings. These regulations focus on protecting life safety in egress paths and public lobbies where occupants gather. Fire-resistive construction depends on surface finishes that limit both flame spread and smoke development during a crisis.

Compliance often requires specific technical documentation. Local jurisdictions frequently add their own layers to the standard code. For example, cities like Phoenix and New York mandate a three-tiered permit process that includes rigorous material specification reviews.

- Class A Rating: Mandatory for finishes in corridors and exit stairs.

- Smoke Development: Materials must produce minimal smoke to maintain visibility during evacuation.

- Permit Documentation: Stamped plans and material safety data are required for commercial occupancy approval.

Non-Combustible Natural Stone and Fireplace Safety

Top Source Stone utilizes 100% natural minerals, primarily Slate and Quartzite. These materials are inherently non-combustible. They offer a significant safety advantage over faux stone imitations, which often rely on flammable polyurethane resins that can ignite or melt when exposed to high temperatures.

Natural stone panels provide a reliable solution for fireplace surrounds and commercial kitchen areas. The mineral composition ensures the material maintains thermal integrity without releasing volatiles or toxic fumes when heated. This makes it a preferred choice for high-heat decorative features and professional environments.

- Material Composition: 100% Slate and Quartzite with zero flammable resins.

- Heat Resistance: Withstands mechanical heat in kitchens and fireplace surrounds without structural degradation.

- UV Stability: Natural minerals resist fading and surface breakdown even in high-temperature zones.

- Safety Advantage: Unlike synthetic veneers, natural stone does not contribute fuel to a fire or emit hazardous smoke.

Scaling the Sourcing: Managing Batch Consistency for 10+ Locations

Multi-site consistency relies on same-vein quarry sourcing and standardized CNC processing. We maintain 95% hue uniformity across all batches to ensure architectural cohesion for large-scale commercial developments.

| Consistency Parameter | Standard Specification |

|---|---|

| Hue Uniformity | 95% within single production batch |

| Sourcing Origin | Same quarry layer/vein per order |

| Cutting Technology | CNC diamond-blade precision edges |

| Quality Verification | HD photo/video of crates before dispatch |

Standardizing Infrastructure for Multi-Site Reliability

Distributed manufacturing often fails due to equipment variance. We eliminate this by installing identical CNC diamond-blade systems across every facility. This ensures every interlocking Z-shape or S-shape panel fits its modular counterpart perfectly, regardless of where the material was cut.

- Real-Time Monitoring: Control systems log pressure and shear data to replicate specific batch conditions exactly across different production lines.

- Centralized QC: Protocols identify anomalies before materials leave the factory, preventing site-specific errors and color drift.

- Maintenance Cycles: Scheduled cleaning and blade replacement between runs prevents cross-contamination and equipment drift that causes jagged edges.

Standardized setup procedures reduce the need for constant on-site adjustments. Once we configure a batch for a specific project, the system locks those parameters to ensure every unit adheres to the same architectural specifications.

Ensuring 95% Hue Uniformity with Same-Batch Quarry Sourcing

Natural color drift can ruin the visual flow of a commercial interior. We solve this through same-batch quarry sourcing. Instead of pulling from different areas of a mountain, Top Source Stone extracts raw material exclusively from the same vein for your specific order.

- 95% Hue Standard: We enforce a strict uniformity threshold for large-scale interior wall applications to prevent patchy visual results.

- Visual Verification: We provide high-definition photos and videos of finished crates so dealers and project managers see the color synchronization before final payment.

- Big 10 Inventory Strategy: We keep high-demand colors like Alaska Gray, Glacier White, and Midnight Slate ready for immediate dispatch across North American ports.

Top Source Stone protects your project timeline by coordinating these logistics through a centralized supply chain. By managing the process from the mountain to the crate, we remove the patchwork risk common with middleman sourcing, providing a reliable finish for every location in your network.

Frequently Asked Questions

Why do commercial architects prioritize natural stacked stone over manufactured alternatives?

Architects specify natural stone for its proven 50-year service life and unique geological character. Unlike manufactured composites that fade or degrade under UV exposure, real stone maintains structural integrity for decades. This provides superior long-term value for commercial assets by eliminating the frequent replacement cycles common with faux substitutes.

Is natural stacked stone compliant with commercial fire safety and building codes?

Natural stone is inherently non-combustible and fire-resistant. Materials like granite and slate do not burn or emit toxic gases when exposed to high temperatures. For strict commercial compliance, we recommend installing stone cladding over fire-rated substrates to meet ASTM E119 standards.

How does natural stone contribute to acoustic management in busy commercial environments?

While dense stone reflects sound, using honed or textured finishes helps disperse noise rather than creating harsh echoes. In hospitality settings, designers pair stone feature walls with absorptive materials like fabric panels to create a balanced, comfortable soundscape.

What are the maintenance requirements for stone walls in high-traffic retail spaces?

High-traffic areas require a daily cleaning routine using pH-neutral solutions and microfiber tools to prevent abrasion. We suggest quarterly assessments to identify mechanical wear and professional sealing every 12 to 18 months to maintain the stone’s protective barrier against moisture and stains.

Can Top Source Stone guarantee color consistency for large-scale, multi-phase projects?

We manage batch consistency by sourcing material from the same quarry vein for each order, achieving 95% hue uniformity. Our production team provides high-definition visual verification of the actual finished crates before dispatch to ensure the batch aligns with the project’s architectural requirements.

Final Thoughts

Generic stone panels often result in patchy color shifts and visible gaps that devalue a commercial property. Our same-batch quarry sourcing and CNC diamond-blade precision ensure 95% hue uniformity and a seamless architectural finish. Investing in 100% natural quartzite or slate eliminates the long-term risk of UV fading and mechanical failure common with synthetic faux alternatives.

Verify our interlocking precision and material density by requesting a sample kit of the “Big 10” inventory. We recommend a 300-square-meter trial order to evaluate our supply chain reliability and consistency before scaling to multi-site developments. Contact our team today to finalize your project specifications or to discuss private label manufacturing options.