Effective estimating and waste (sales) planning is the only barrier between a profitable masonry project and a costly logistical delay. Underestimating material needs results in mid-project shutdowns and expensive small-batch shipping fees, while over-ordering ties up capital in unusable inventory. Precise calculations ensure that jobs remain on schedule and protect the bottom line from the margin erosion caused by inaccurate procurement.

This guide provides a standard operating procedure for quantifying stone veneer requirements by breaking down the differences between net and gross area measurements. We detail the process for calculating linear corner feet, subtracting architectural openings, and applying the 10 to 15 percent professional waste standard. Following these steps maintains batch consistency across the entire substrate and prevents the downtime caused by material shortages.

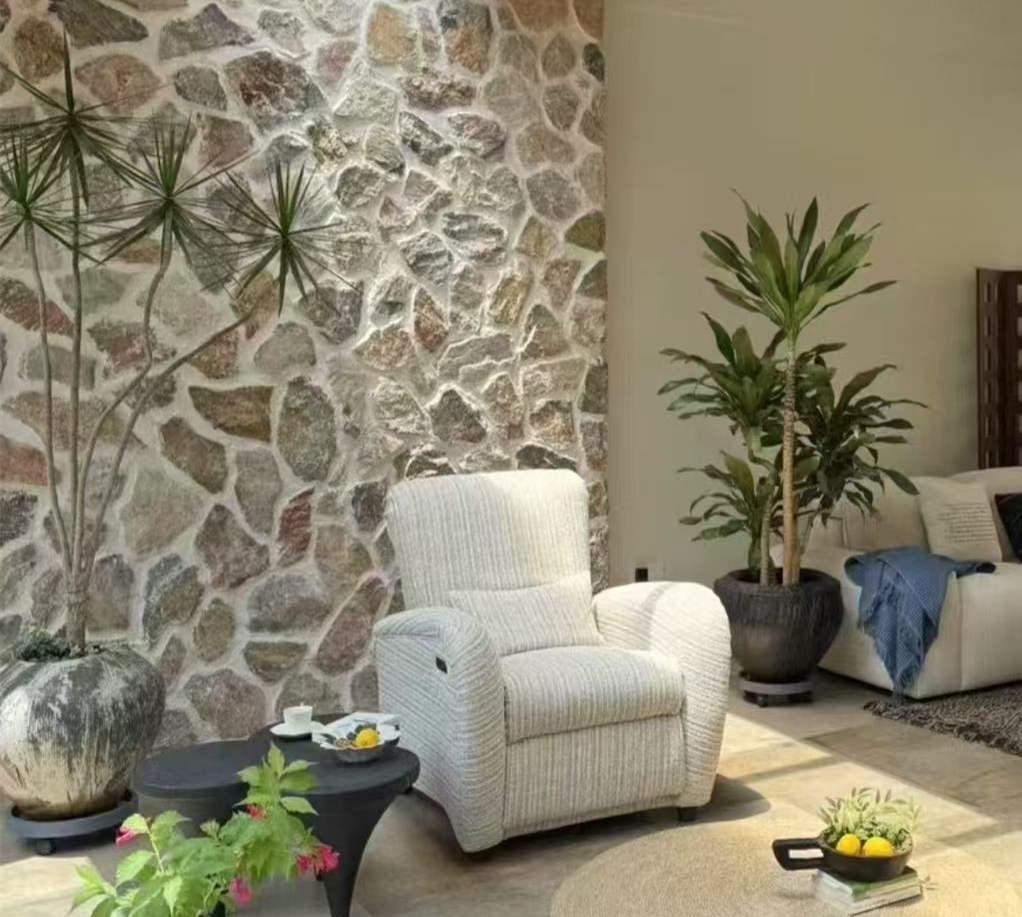

Measuring Flat Surfaces: The Net vs. Gross Area

Precision in masonry estimation requires a clear distinction between the raw substrate dimensions and the actual material volume needed to achieve full-depth visual integrity using loose stone veneer.

Defining the Net Installation Surface

We define the net area as the specific square footage of the wall substrate that requires stone coverage, strictly excluding all architectural openings such as windows, doors, and fireplaces. In professional B2B procurement, we calculate this by measuring the height and width of each individual wall section. This figure serves as the baseline for essential logistics, including the quantity of specialized adhesives and the deployment of labor teams for the hand-laid installation process.

Accurate net measurements prevent the common mistake of over-ordering foundational materials like cement board. Since our Thin Stone Veneer features an individually sawn-back finish, the net area directly correlates to the bonding surface. For 2026 project standards, contractors use these figures to lock in labor cost estimates before any material waste or architectural corner wraps are factored into the final bill of materials.

Calculating Material Requirements for Loose Stone

While net area defines the wall size, the material ordered must account for the organic nature of a bespoke random-lay pattern. Unlike mass-produced Z-shape panels that rely on fixed interlocking edges, loose stone veneer requires a more nuanced approach to volume. We calculate the material requirement based on the physical footprint needed to eliminate visible gaps while maintaining the zero-repeat natural variation expected in high-end masonry.

| Measurement Metric | Technical Calculation | B2B Project Impact |

|---|---|---|

| Net Surface Area | (Wall Height x Width) – Openings | Sets baseline for adhesive and labor costs. |

| Gross Material Volume | Net Area + 10-15% Waste Factor | Ensures batch consistency from a single quarry vein. |

| Linear Corner Footage | Total Vertical Height of All Corners | Determines quantity of L-shaped corner wraps needed. |

To ensure the site team has sufficient material for full coverage, suppliers provide dimensions that reflect the total physical stone required to fill the net space. This volume includes the necessary surplus to handle the random sizes of natural quartzite or sandstone. Managing this data correctly ensures the finished feature wall appears as a massive, structural dry-stack installation rather than a thin application.

Managing the 8-12% Measurement Variance

Professional estimates in 2026 recognize a typical variance where the required material volume exceeds the net surface area by approximately 8-12%. This discrepancy arises from the geometry of random-lay masonry. Standardizing these figures using BOMA or similar architectural guidelines ensures transparency between the factory and the distributor. By documenting both the net area and the gross requirement in the initial quote, we prevent pricing disputes and logistical delays.

- Use net area for calculating substrate prep and waterproofing requirements.

- Apply the 8-12% variance to determine the final crate count for shipping.

- Maintain quarry-to-project consistency by ordering the full gross amount from a single batch.

Establishing these measurement methodologies at the procurement phase protects the project’s bottom line. When distributors provide clear data on both usable surface area and total material volume, they provide the site team with the resources needed for a flawless, artisan-style installation that maintains structural and aesthetic integrity over the building’s lifecycle.

Calculating Corners: Why Linear Feet Matters

Calculating outside corners in vertical linear feet rather than square footage is the only way to ensure “Full-Depth Visual Integrity” and prevent significant material shortages during the final phases of installation.

Accurate project estimation requires a strict distinction between flat wall surfaces and vertical corners. Estimators must measure the total height of every external corner in the project area to determine the required linear footage for L-shaped components. Unlike flat panels that only cover a two-dimensional plane, these corners wrap around the substrate to mimic the appearance of full-bed structural masonry. In 2026, high-end project planning relies on these vertical measurements to maintain a consistent staggered joint pattern across the entire facade.

| Corner Component Spec | Dimension Range | Unit Weight |

|---|---|---|

| L-Shape Long Side | 150–250mm | ~25 kg / Linear Meter |

| L-Shape Short Side | 50–100mm | ~25 kg / Linear Meter |

| Veneer Thickness | 25–40mm | Included in Linear Weight |

L-Shaped Units and Installation Efficiency

Top Source Stone provides pre-fabricated, individually sawn-back L-shaped corner units that eliminate the need for complex on-site miter cuts. Traditional field-mitered corners often lead to material breakage and visible seams that ruin the organic aesthetic of the stone. By using dedicated corner components, contractors create an “Authentic Masonry Corner Wrap” that provides the look of heavy structural blocks while utilizing the lightweight advantages of thin stone veneer.

- Precision-sawn backs reduce on-site labor costs by up to 30% by providing a flat bonding surface for immediate adhesion.

- Interlocking L-shaped units remove the requirement for specialized masonry saws at every corner transition.

- The random-size philosophy of these corners ensures a bespoke finish that avoids the repetitive, artificial look of pre-glued panels.

Integrating Corner Math into Total Surface Area

Calculating corners correctly prevents over-ordering flat panels because these L-shaped pieces cover a portion of the flat wall area. Each linear foot of a corner typically consumes approximately 0.75 to 1.0 square foot of wall coverage. To find the net quantity of flat stone required, subtract the square footage covered by corners from the gross wall area. For example, if a project has 80 linear feet of corners, these pieces will cover roughly 60 to 80 square feet of the wall, reducing the need for flat veneer by that same amount.

Dual-measurement strategies—tracking both linear and square footage—help maintain tight budgets and minimize environmental impact. By precisely accounting for how corners integrate with the flat surface area, project managers avoid the common mistake of double-ordering material for corner zones. This data-driven approach ensures that the “Quarry-to-Project Consistency” is maintained, as the entire order of loose stones and corners can be pulled from the same quarry vein simultaneously.

Premium Factory-Direct Stacked Stone Ledger Panels

The “Waste Factor”: Why 10-15% is the Professional Standard

Precision stone masonry requires a calculated overage; the 10-15% waste factor is a technical necessity to mitigate losses from custom trimming, site logistics, and architectural complexity.

Accounting for Cutting and Trimming Losses

Traditional estimation often underestimates the physical reality of on-site installation. When masons work with loose thin stone veneer to create a bespoke random-lay pattern, they perform dozens of custom cuts to fit pieces into specific wall dimensions. End-of-row cuts frequently create small offcuts that builders cannot reuse, as the natural edges required for a seamless look are lost during the trim. This material loss is particularly high in 2026 projects featuring complex architectural shapes, such as gables or sloped walls, where diagonal fitting generates a high volume of scrap.

Industry data suggests that linear trimming alone accounts for a significant portion of the total waste margin. Installers must have the flexibility to discard pieces that do not fit the organic texture of the wall. Without a 10-15% buffer, crews often find themselves unable to complete the final rows of a project, leading to costly delays and logistics hurdles.

| Project Complexity | Joint Specification | Recommended Waste Factor |

|---|---|---|

| Standard Residential (Flat Walls) | Standard Mortar Joint | 10% |

| Commercial (Windows/Openings) | Tight / Dry Stack | 15% |

| High Complexity (Gables/Arches) | Artisan Over-Grout | 20% – 25% |

Managing Handling and Transit Breakage

Natural stone products undergo multiple stages of logistics, from the factory to international shipping and local site delivery. Even with high-density quartzite or granite, minor chipping or cracking can occur during transit. Professionals manage this by using slightly damaged stones for fill-in pieces or foundation-level cuts where the visual impact is minimal. This maximizes material utility while keeping the project on schedule.

The 10-15% buffer ensures the masonry crew has a constant supply of pristine stones for high-visibility focal points. In B2B supply chains, waiting for replacement crates due to minor breakage is inefficient. A professional order accounts for these variables at the start, maintaining project momentum and ensuring the “Full-Depth Visual Integrity” of the installation remains uncompromised.

Impact of Design Complexity on Material Needs

The physical layout of a wall directly dictates the required overage. Features such as windows, doors, and electrical outlets demand intricate cuts to maintain a natural look. Wraparound corners and pillars also require more material than flat surfaces. Using “Authentic Masonry Corner Wraps” is essential for a professional finish, but these L-shaped pieces must be fitted precisely, which naturally increases the waste percentage compared to basic flat cladding.

Ordering the full professional standard at the beginning of the project prevents color matching issues. Since Top Source Stone provides material from the same quarry vein per order, a secondary order placed weeks later may show subtle natural variations. Securing all necessary stone—including the waste factor—guarantees quarry-to-project consistency and long-term aesthetic harmony.

How to account for window and door openings?

Precise estimation for Thin Stone Veneer requires a strict transition from gross wall area to net coverage, specifically accounting for the architectural depth of L-shaped corner returns at every jamb and header.

Calculating the net square footage of the wall

Reliable budgeting for 2026 projects starts with a clear distinction between gross wall area and actual stone coverage. You must calculate the total square footage of the wall and then subtract the area of every window and door. This ensures you only pay for the material being installed on the substrate and avoids the common error of over-ordering based on raw wall dimensions. For professional estimates, use the final exterior dimensions of the frames or trim boards to establish these subtraction points.

- Subtract the total square footage of every window and door from the gross wall measurement to reach the net area.

- Ignore small openings under 2 square feet in your subtractions; these function as a safety buffer for the complex cuts required in tight spaces.

- Base all measurements on the outer edge of the window sills and door casing to reflect real-world installation boundaries.

Utilizing architectural software for digital takeoffs

Manual calculations often fail to account for how a 25–40mm stone thickness interacts with existing structural elements. Modern estimation services utilize platforms like Revit or Bluebeam to trace the perimeter of every opening with high precision. This digital approach allows us to visualize how the stone will meet window sills and door headers before the first crate leaves our factory. Because our Thin Stone Veneer is individually sawn-back, digital modeling helps determine the exact placement of loose pieces to minimize onsite adjustments.

- Use architectural software to trace the exact perimeter of openings for automated, error-free quantity takeoffs.

- Map out the “Bespoke Random-Lay Pattern” digitally to predict where cuts will fall relative to structural door headers.

- Integrate 3D modeling to ensure the stone thickness does not obstruct window operation or exceed sill depth.

Planning for stone returns with L-shaped corners

Window and door openings create exposed edges that demand more than just flat stone panels. To achieve Full-Depth Visual Integrity, you must use matching L-shaped corner pieces for the returns of window jambs and door recesses. These pieces wrap around the opening, making the veneer indistinguishable from full-depth masonry. We recommend calculating the linear footage of all vertical opening edges separately to determine the exact number of corner units required for a professional finish.

- Apply an “Authentic Masonry Corner Wrap” using L-shaped pieces to every window jamb and door recess.

- Calculate the linear footage of vertical opening edges to order the correct volume of corner units (Approx. 25 kg/lineal meter).

- Use pre-fabricated corner pieces to eliminate the need for time-consuming and aesthetically inferior miter cuts on-site.

Adjusting waste factors for perimeter detailing

Intricate cutting around lintels, sills, and headers generates significantly more scrap than a standard flat wall installation. While a 10% waste factor is typical for large unobstructed areas, walls with multiple small windows require an increase to 15%. This accounts for the specialized trimming needed to fit the “High-Density Quartzite Integrity” of our stone into tight architectural voids. Proper allocation for these custom horizontal rips ensures the installation crew never runs short during the final detailing phase.

- Increase the standard waste factor to 15% for any wall featuring more than three openings per 20 square meters.

- Account for the specific stone series; more textured random-lay stones require more aggressive trimming at the perimeter.

- Allocate extra material specifically for header stones, as these frequently require horizontal rips to fit the structural opening height.

Batch Consistency: Ordering enough stone the first time

Securing the total project volume in a single order eliminates geological variance and protects the visual integrity of hand-laid masonry.

Natural Variation and Aesthetic Continuity

Natural thin stone veneer remains a unique product of the earth, where every slate, quartzite, or marble piece carries distinct mineral hues and textures. These characteristics depend entirely on the specific section of the quarry extracted at a given time. Unlike mass-produced synthetic alternatives that rely on repetitive molds, our individually sawn-back loose stones offer zero-repeat natural variation.

Ordering the entire quantity upfront ensures that all material originates from the same quarry vein or “layer.” This quarry-to-project consistency is vital for maintaining a harmonious appearance across expansive feature walls or multi-story facades. A single-batch purchase guarantees that the raw mineral composition and the secondary processing, such as surface cleaning and sorting, remain uniform.

- Every natural stone piece is unique, demanding a unified sourcing strategy.

- Sourcing from the same quarry layer minimizes color shifts between sections of the installation.

- Unified batches maintain aesthetic flow in both high-end residential and large-scale commercial developments.

Risks of Supplemental Orders and Batch Mismatches

Attempting to fill shortages with secondary orders later in the project often results in a visible “patchwork” effect. Even with strict quality controls, stone extracted six months apart may show slight shifts in iron oxidation or quartz density. Furthermore, differences in factory calibration cycles for the 25–40mm thickness can complicate the installation of a bespoke random-lay pattern, leading to uneven wall depths.

Secondary orders also introduce logistics risks. Waiting for matching inventory to become available can stall a project, increasing labor costs and delaying site handover. Securing all material in the initial container protects the schedule and ensures the masonry team works with a consistent graded selection from start to finish.

The Role of the 10-15% Waste Factor

We advocate for a professional waste factor of 10-15% as a standard procurement safeguard. This surplus accounts for the intricate cuts required for edges and the authentic masonry corner wraps that define premium architecture. Having an adequate reserve from the original batch eliminates the need for emergency reorders of small quantities, which are costly to ship and difficult to match perfectly.

- A 10-15% buffer ensures installers have sufficient matching stone for mitered cuts and specialized fitting.

- Upfront surplus protects the timeline by preventing shortages during the final phase of installation.

- Waste management is more efficient when all material arrives in one coordinated delivery.

Advanced Batch Tracking and Logistics in 2026

Modern B2B inventory systems now allow for precise tracking of extraction cycles to support large-scale architectural requirements. Our logistics team utilizes real-time monitoring to group crates from the same extraction period, specifically for high-volume orders. This 2026 standard involves documenting batch IDs, ensuring that multi-phase commercial developments receive consistent stone across different delivery windows.

Strategic loading and reinforced plywood packaging further protect batch integrity during international transit. By tracking the material from the quarry face to the final crate, we provide dealers and wholesalers with a documented chain of consistency, ensuring that the high-density quartzite or granite ordered today matches the technical and aesthetic specs required for the duration of the build.

Conclusion

Accurate measurements and a disciplined 10-15% waste factor ensure a steady workflow while preventing the logistical delays associated with material shortages. Combining flat square footage with linear corner calculations creates a professional-grade estimate that maintains the visual integrity of the project. Securing the entire quantity in a single batch protects the natural color harmony inherent in quarry-sourced stone veneer.

Review our technical specifications at topsourcestone.com to select the right stone profile for your current architectural requirements. You can also contact our team to request a digital catalog or discuss wholesale sourcing for your inventory needs.

Frequently Asked Questions

How to calculate stone veneer square footage?

To calculate the required square footage, measure the width and height of each wall section intended for coverage. Multiply the width by the height of each section to find the gross area, then sum these totals to reach your overall project square footage.

How much waste should I allow for stone veneer?

Industry standards recommend adding a 10% to 15% waste factor to your final measurement. This extra material accounts for specialized cuts, trimming around obstacles, and potential breakage during transit or installation, ensuring you have enough matching material to complete the job.

How to measure corners for stone veneer?

Corners are measured in linear feet. Measure the vertical height of all external corners that require stone. Because corner pieces also cover a portion of the flat wall surface (typically about 0.75 square feet per linear foot), you should subtract this calculated area from your total flat stone requirement to avoid over-ordering.

How many square feet are in a box of stone?

Most manufactured stone veneer is sold in “handy boxes” containing 10 to 12 square feet of flat pieces or 10 linear feet of corner pieces. For larger commercial orders, stone is often packaged in bulk crates containing approximately 100 square feet.

Do I subtract windows from stone area?

Yes, you should subtract the square footage of large openings such as windows, doors, and garage entries from your total wall area. However, it is professional practice to leave small openings (under 2 square feet) in the calculation to ensure you have enough material for the intricate cuts required around those voids.

How much stone is in a ton?

For traditional full-bed depth stone (3 to 5 inches thick), one ton generally covers between 35 and 45 square feet. If you are using natural thin veneer, the coverage per ton is significantly higher, but these products are more commonly sold by the square foot for precision bidding.