Executing a successful B2B strategy in the stone industry requires moving beyond generic commodity sales that leave your margins vulnerable to constant price wars. Many distributors struggle with brand dilution when they source identical products as their competitors, which eventually leads to a loss of market share and decreased customer loyalty. Transitioning to a private label model secures your competitive advantage by turning standard stone slabs into proprietary assets that customers cannot find elsewhere.

This technical overview provides the framework for building a private label brand through Top Source Stone, covering everything from logistics to manufacturing standards. You will find specific details on custom packaging and pallet branding, quality assurance protocols that protect your brand integrity, and strategies for managing OEM lead times to ensure supply chain stability. We treat these elements as a standard operating procedure for distributors looking to scale their operations through direct factory sourcing and customized product lines.

The Benefits of Private Labeling for Stone Distributors

Transitioning to a private label model allows stone distributors to capture up to double the gross margin of national brands while building long-term business equity through exclusive, regionalized product collections.

Increased Profit Margins and Revenue Growth

Private labeling empowers stone distributors to capture significantly higher margins by sourcing directly from the factory and eliminating the layers of national brand markups. In 2026, distributors using this model often realize double the gross margin compared to those reselling established brands. This shift turns the distributor from a middleman into a brand owner with full control over their pricing architecture.

- Factory-direct pricing provides a decisive competitive edge when bidding for large-scale commercial and residential stone projects.

- Eliminating middleman costs creates room for flexible retail pricing while protecting the bottom line from inflationary pressure.

- Direct sourcing enables better cash flow management through transparent payment terms and predictable landed costs.

Exclusive Brand Identity in Regional Markets

Custom branding transforms a generic stone product into a unique asset that builds equity for the distributor’s business. Instead of promoting a third-party manufacturer, distributors build direct customer loyalty to their own label. This differentiation is critical in crowded markets where competitors often sell identical products under the same national banner.

- Custom-printed packaging and unique product series names, such as specific “Rough” or “Flat” series, differentiate inventory from local competitors.

- Distributors can curate collections that specifically mirror the architectural aesthetic preferences of their local geography.

- Private labels allow distributors to control the marketing narrative, focusing on the specific durability and color fastness of their chosen stone veins.

Direct Manufacturing Oversight and Quality Assurance

Partnering directly with a quarry-owning manufacturer ensures consistent product quality and supply chain transparency. We provide distributors with a three-stage inspection process, covering everything from infrared cutting to the final packaging phase. This direct link to the source minimizes the risk of the quality “drift” often seen when national brands swap suppliers to cut costs.

- Direct communication with the factory facilitates better control over stone color consistency and adhesive strength for large-scale orders.

- Access to the same quarry layer per order ensures color harmony across the entire project installation.

- Supply chain security improves through direct access to raw materials, reducing the risk of inventory shortages during high-demand periods.

Tailored Product Specifications for Local Projects

Private labeling enables distributors to influence product design and technical specifications to meet regional architectural requirements. Whether it is adjusting the thickness for specific wall substrates or requesting a unique finish, OEM services allow for a level of customization that standard wholesale cannot match.

- Distributors can request custom panel formats or specific stone types, like premium Marble or Slate, to match trending local designs.

- OEM adjustments in sizing and thickness ensure compliance with regional building codes and structural weight limits.

- Developing exclusive finishes provides a unique product line that competitors cannot easily replicate through standard sourcing channels.

Custom Packaging: Boxes, Pallets, and Branding

In 2026, the transition from generic logistics to integrated brand packaging allows stone distributors to capture double the gross margin by establishing direct brand equity on the job site.

Custom Printed Boxes for Brand Recognition

Distributors who utilize our full OEM services strengthen their market presence by moving away from anonymous packaging. We print company logos, contact details, and specific SKU information directly onto reinforced cardboard cartons. This eliminates the need for secondary labeling and ensures that your brand remains visible from the warehouse to the final installation site. High-quality digital printing also allows for the inclusion of clear installation instructions and safety warnings in multiple languages, supporting local contractors and reducing liability.

| Packaging Feature | Standard Generic Supply | Top Source Stone OEM |

|---|---|---|

| Exterior Branding | Plain brown box / No logo | Full-color digital logo & SKU info |

| Crate Material | Untreated softwood pallets | ISPM-15 Fumigated Solid Wood |

| Damage Protection | Minimal padding | Corner guards & multi-step padding |

| Documentation | Paper packing slip only | Digital tracking & multi-lingual guides |

Secure Palletization with Fumigated Wooden Crates

Natural stone requires heavy-duty protection to withstand international transit and warehouse handling. We utilize heat-treated and fumigated wooden crates that comply with international ISPM-15 shipping regulations, preventing customs delays and biological risks. Each crate base is reinforced to support the 950kg gross weight typical of our thin stone veneer layers. To prevent edge chipping and surface scratches on high-density quartzite or marble, we apply a multi-step internal padding system and rigid corner protectors. This ensures that the individually sawn-back stones arrive ready for immediate hand-laid installation.

Strategic Container Loading and Logistics Optimization

Our logistics team maximizes container volume while ensuring cargo stability. We arrange 110cm x 110cm crates strategically to eliminate gaps and minimize the risk of shifting during sea freight. We strictly manage weight distribution to meet 2026 safety standards; for example, we maintain a 17.5-ton limit for standard USA port entries while offering heavy-weight loading up to 26.5 tons for regions with approved overland transport permits. Detailed packing lists and digital tracking accompany every shipment, streamlining the customs clearance process for our B2B partners.

Sustainable Packaging Trends for 2026

Responding to global environmental mandates, we integrate eco-friendly materials into our supply chain without sacrificing structural integrity. Our 2026 packaging options include:

- Recyclable cardboard inserts and reduced-plastic strapping for lighter-weight shipments.

- Low-VOC digital printing techniques that reduce chemical waste compared to traditional ink-heavy methods.

- Reusable plywood crates designed for multi-stage distribution within regional retail networks.

We balance these sustainability goals with the high-strength requirements necessary for heavy natural stone. By adopting these trends, distributors meet the green building requirements often requested by architects and large-scale commercial developers, further differentiating their private label brand in a competitive landscape.

Premium Natural Stone for Architectural Excellence

Quality Assurance: Maintaining Brand Integrity

Reliability in the B2B stone sector depends on a manufacturer’s ability to eliminate material variance and ensure that every crate delivered in 2026 matches the approved architectural sample.

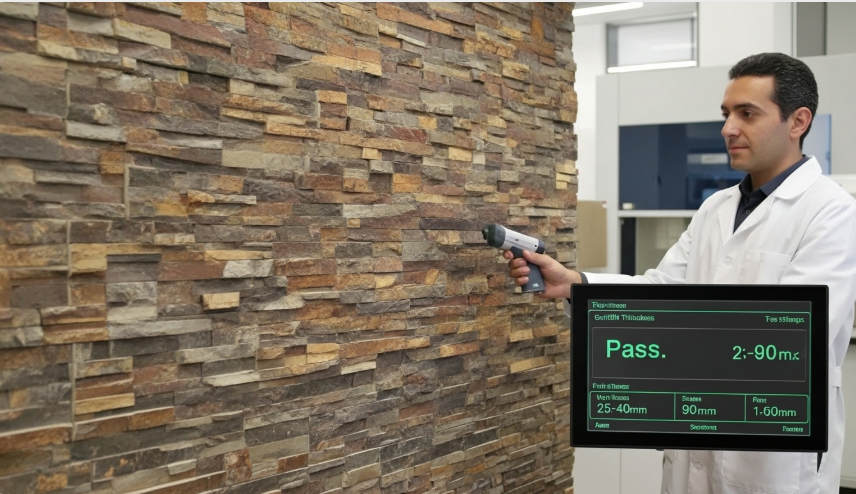

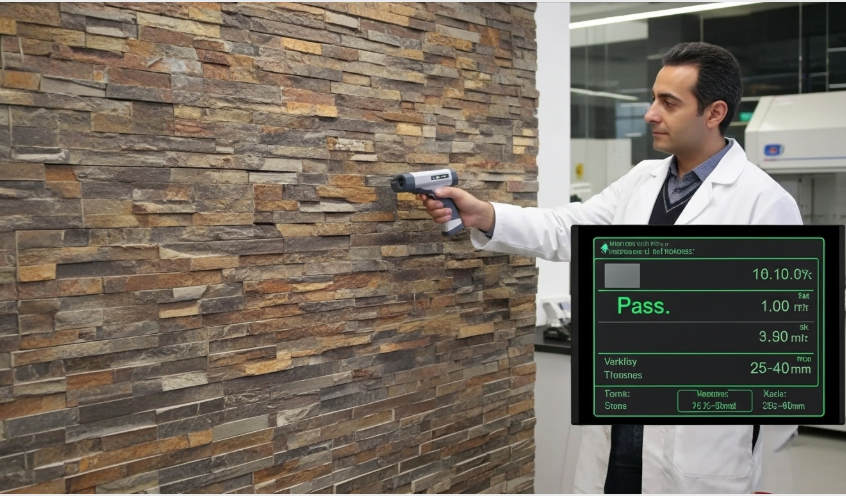

Three-Stage Manufacturing Inspections

We execute a rigorous triple-check system during production to ensure every thin stone veneer piece meets 2026 architectural standards. Most quality failures in the stone industry occur because inspections happen only at the end of the line. We change this by inspecting units immediately after the initial stone cutting to verify dimensional accuracy before any further processing occurs.

| QA Phase | Standard Market Practice | Top Source Stone Protocol |

|---|---|---|

| Raw Sourcing | Mixed batches from various quarry layers. | Single-vein sourcing per order for color harmony. |

| Dimensional Control | Manual gauging with ±10mm tolerance. | Infrared precision cutting for exact thickness. |

| Backing Finish | Rough or uneven natural backs. | 100% Sawn-back for maximum adhesion. |

A second review focuses on the backing finish. We ensure a 100% sawn-back surface, which provides the flat bonding area necessary for individual hand-laid installations. Final quality audits take place before packing to confirm that every crate ready for delivery is free of structural defects or contamination.

Precision Processing for Seamless Installation

Advanced technical processes prevent common stone failures and facilitate efficient installations for large-scale commercial projects. We use infrared cutting equipment to achieve precise measurements, allowing our random-size loose stones to be laid in a bespoke pattern without the dimensional inconsistencies that slow down masonry teams.

- Precision-sawn backs reduce on-site labor costs by up to 30% compared to rough-back stones.

- Strict thickness control between 25–40mm ensures lightweight advantages for modern substrates.

- Our individually sawn-back pieces eliminate the need for excessive mortar, providing a permanent bond.

Direct Sourcing and Material Consistency

Owning the quarries allows for total control over raw material grading and aesthetic harmony across high-volume orders. We source raw materials directly from our own quarry sections to maintain a stable supply chain throughout 2026. This “Quarry-to-Project” consistency ensures that stones for specific projects come from the same vein to provide visual uniformity.

Production teams grade stones before assembly to ensure color tones remain within the acceptable range for B2B distributors. By managing the source, we guarantee zero-repeat natural variation, giving projects an organic texture that manufactured concrete alternatives cannot replicate.

Verifiable Durability for B2B Partnerships

Providing long-term value through natural stone properties helps distributors build lasting trust with their clientele. The 100% natural stone composition—including high-density quartzite and granite—ensures colors stay permanent and do not fade from UV exposure. These materials are climate-tested for resilience against harsh freeze-thaw cycles.

- Natural mineral composition offers lifetime color fastness and moisture resistance.

- We provide products that require minimal maintenance, protecting the brand reputation of contractors and designers.

- Logistics teams use reinforced plywood crates and heavy-duty strapping to maintain product integrity during international transit.

Lead Times and Supply Chain Security for OEM

Direct quarry ownership and swn-back precision eliminate middleman delays, securing a predictable 20-day production window for high-volume 2026 commercial contracts.

Factory-Direct Production and Quarry Integration

We manage the entire production cycle from our own quarries, removing the middleman dependencies that typically cause lead time fluctuations in the stone industry. Direct manufacturing oversight allows us to provide precise production scheduling, which remains essential for meeting the tight delivery windows of modern commercial projects. By owning the raw material source, we guarantee a steady flow of natural stone even during high market demand or regional supply instability.

Controlling the supply chain from the source ensures material consistency across large-scale OEM orders. We extract stone from the same quarry vein per order to minimize natural color shifts, providing the color harmony that architects and developers require for feature wall continuity. This quarry-to-project consistency protects the distributor’s reputation for quality.

Global Logistics Management and Shipping Reliability

Our logistics department handles the export of over 220 containers annually, using strategic loading techniques to maximize crate density and reduce unit shipping costs. We utilize reinforced packaging, including fumigated solid wood or plywood crates, designed to withstand the stress of long-distance sea freight and multiple transshipment points. Every pallet is secured with heavy-duty strapping and stretch wrap to prevent stone movement during transit.

| Supply Chain Factor | Broker/Trading Sourcing | Top Source Stone (Direct) |

|---|---|---|

| Standard Lead Time | 45 – 60 Days (Unpredictable) | 20 – 25 Days (Guaranteed) |

| Color Consistency | Mixed from multiple small yards | Single-vein quarry extraction |

| Logistics Standards | Third-party forwarder reliance | Tier-one carrier partnerships |

| Packaging Type | Standard low-grade crates | Fumigated solid wood/Plywood |

Quality Assurance Systems for Large-Scale OEM Orders

We implement a three-stage quality check that focuses on dimensional integrity and material strength. Our technicians inspect the raw stone after initial extraction, monitor the precision of the sawn-back process, and perform a final audit immediately before the crates are sealed. This ensures every piece of thin stone veneer stays within the 25–40mm thickness tolerance, which is critical for lightweight wall substrates and structural safety.

The sawn-back finish provides a flat bonding surface that reduces on-site masonry labor by up to 30%. We use precision-cutting equipment to ensure these surfaces are perfectly level, maximizing adhesion during installation. By preventing defective units from entering the supply chain, we protect our OEM partners from the high costs of field failures and project delays.

Proactive Supply Chain Risk Mitigation in 2026

Strategic planning and safety stock management protect our partners from unforeseen global trade disruptions. We maintain reserves of popular stone types like Black Quartzite and Ivory Sandstone to buffer against sudden spikes in order volume. Our 2026 strategy emphasizes diversified shipping routes and partnerships with multiple tier-one carriers to avoid regional port congestion.

- Continuous monitoring of quarry capacity allows for accurate, reliable lead time estimates during the bidding phase.

- Real-time shipment tracking and automated documentation provide clear visibility from the factory floor to the final destination port.

- Strict adherence to weight limits, such as the 17.5-ton USA port standard, prevents customs delays and extra handling fees.

- Before balance payments, we provide detailed photos and videos of the finished inventory to ensure total transparency.

Case Studies: Successful Private Label Partnerships

Strategic private label partnerships turn natural stone into a high-margin proprietary asset by leveraging quarry-direct sourcing and bespoke logistics to eliminate middleman overhead.

Regional Distributors Scaling with Custom Collections

Regional stone suppliers in 2026 use private labeling to separate their inventory from generic market offerings. By curating specific textures like the Rough Series, these distributors capture the mountain and rural architectural markets under their own proprietary brand names. This approach allows them to build local brand equity that is not tied to a specific manufacturer’s catalog.

- Factory-direct OEM services eliminate middleman costs, giving partners 100% control over their local pricing strategies and profit margins.

- Custom-printed packaging ensures every pallet arriving at a job site reinforces the distributor’s brand authority rather than the manufacturer’s.

- Access to individually sawn-back loose stone provides a 30% reduction in onsite labor costs, a key selling point for regional masonry contractors.

Luxury Hospitality Projects and Branded Marble Series

Architectural firms and luxury developers integrate the Marble Series into high-end interior portfolios to increase property valuation. Many firms brand materials like Royal White as an exclusive “Signature Collection” within their developments. This creates a sense of scarcity and exclusivity that justifies premium luxury pricing for investors and buyers.

- The use of matching L-shaped corner pieces delivers a seamless, professional finish that provides full-depth visual integrity on feature walls.

- Private label partners receive detailed quality control reports from a three-stage inspection process, ensuring brand integrity across multi-phase projects.

- Quarry-to-project consistency ensures that stone sourced for Phase II perfectly matches the mineral profile of Phase I.

National Retailers Optimizing Supply Chains via OEM

Large-scale retail chains utilize the Pencil Series to meet the 2026 demand for modern, linear aesthetics while securing long-term supply stability. These partners rely on heavy-duty logistics and strategic container loading to maintain high inventory turnover without the risk of material breakage during international transit.

- Retailers benefit from fumigated wooden crate packaging designed to withstand rigorous international logistics and port handling requirements.

- Direct access to quarry-owned resources allows national chains to maintain color consistency across thousands of square feet, which is critical for large retail rollouts.

- Supply chain security is reinforced by the ability to move over 220 containers annually, providing retailers with predictable lead times and reliable stock levels.

Conclusion

Private labeling transforms a commodity into a unique brand asset, allowing distributors to command higher margins and build long-term customer loyalty. By leveraging direct factory resources like custom packaging and quarry-to-project consistency, your business maintains strict control over quality and supply chain security. These strategic steps differentiate your portfolio in a competitive market while ensuring every thin stone veneer installation reflects your high professional standards.

We invite you to discuss your specific branding requirements and explore our custom packaging options for your next project. You can contact our team for a private label consultation or a sample kit to see how our individually sawn-back stones fit your brand identity.

Frequently Asked Questions

How to start a private label stone brand?

To start a private label stone brand, begin by identifying a specific market niche and partnering with a direct manufacturer to establish a controlled supply chain. Focus on creating tailored product specifications that meet regional needs and implement rigorous quality assurance protocols. This strategic approach allows distributors to capture roughly twice the gross margin of national brands while building long-term customer loyalty through unique branding.

What is the MOQ for custom stone packaging?

Minimum Order Quantities (MOQ) for custom-branded stone packaging typically range from 50 to 100 specialized crates or a minimum of one full container load (FCL). While requirements vary by manufacturer, many high-end OEM partners offer flexible branding options, such as branded corner protectors or laser-etched labels, to accommodate growing distributors as they scale their private label presence.

Can I customize stone colors for my brand?

Yes, customization is a core benefit of private labeling. For engineered surfaces like quartz or sintered stone, you can work with manufacturers to develop proprietary pigment blends and patterns. For natural stone, customization involves selecting exclusive quarry blocks and applying unique finishes—such as leathered, honed, or brushed textures—to differentiate your product line from standard market offerings.

Who is the best OEM stone manufacturer?

The best OEM stone manufacturers are typically located in major global stone hubs such as Italy, Spain, India, and China (specifically the Xiamen region). Top-tier partners are those who offer integrated production capabilities, sustainable sourcing certifications, and advanced quality control systems that mirror the standards of premium global brands, ensuring your private label remains competitive on both price and quality.

How to protect stone branding during shipping?

Protecting stone branding requires a combination of durable material and specialized logistics. Use weather-resistant industrial labels and laser-engraving on the stone edges to ensure the brand remains visible. Additionally, utilize heat-treated, branded wooden crates with high-density polyethylene (HDPE) liners and reinforced corner protectors to prevent breakage and environmental damage during international transit.

Benefits of direct factory stone sourcing?

Direct factory sourcing significantly reduces procurement costs by eliminating intermediary markups, leading to higher gross margins for distributors. It provides direct control over the supply chain, enabling faster response to market trends, enhanced quality assurance, and the ability to offer more competitive pricing. Furthermore, it allows for better collaboration on sustainable sourcing practices, which strengthens brand recognition and customer loyalty.