Choosing the right stone types is the primary factor in preventing premature veneer failure and avoiding the massive liability of moisture intrusion or structural degradation. Architects and builders face significant risks when they specify materials that cannot withstand the physical stress of thin-cutting, leading to excessive site waste and inflated labor costs. Selecting a stone that fails to meet project-specific environmental standards often results in costly rework that eats into narrow profit margins.

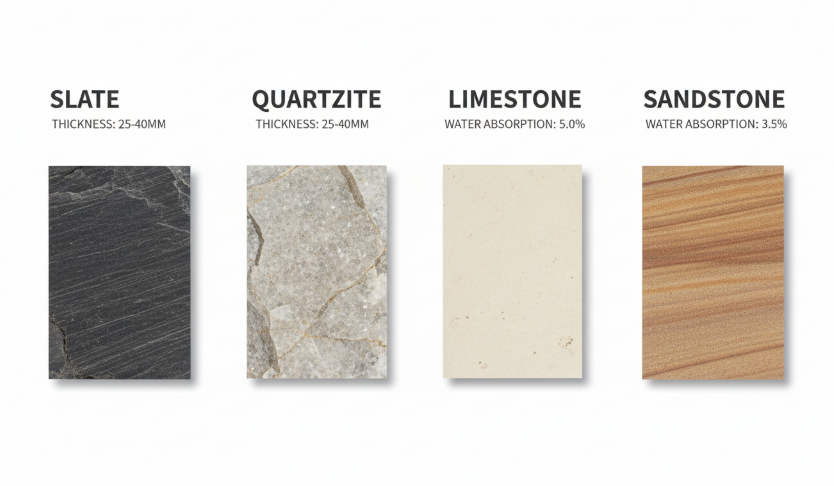

We break down the technical properties of slate, quartzite, sandstone, and limestone to determine which species provide the best stability for thin-veneer applications. This analysis compares water absorption rates, mineral density, and split-face characteristics to provide a technical standard for material selection. Use these metrics as a standard operating procedure for ensuring long-term durability in high-traffic or exterior environments.

Which stone species are best suited for thin cutting?

Successful thin-cut veneers require minerals with high density or distinct cleavage planes to maintain structural integrity at 0.75-inch profiles without fracturing during high-speed fabrication.

Manufacturing thin stone veneer requires raw materials that can withstand the mechanical stress of diamond-blade or infrared cutting without losing their surface texture. Not every stone species qualifies for this process. We focus on materials that offer a balance between mineral hardness and the ability to be sliced into narrow profiles while maintaining a 100% sawn-back finish for secure masonry bonding.

Slate and Quartzite for Intricate Linear Designs

Slate and quartzite remain the industry standards for modern, pencil-style ledger panels and loose thin veneers. Slate features natural cleavage planes, allowing us to produce clean, thin layers that do not crumble during the fabrication phase. This makes it ideal for projects requiring deep textures but low overall weight. Quartzite provides a different advantage; its extreme hardness allows it to stay stable even when cut into very narrow 0.75-inch strips.

- Slate’s mineral structure permits precise slicing without the excessive micro-fractures common in softer sedimentary stones.

- Dense quartzite varieties, like our Blue or Ice White selections, maintain a 7 Mohs hardness rating even at reduced thicknesses.

- Modern 2026 standards utilize these species for high-detail feature walls that demand durability without the bulk of traditional full-bed stone.

| Stone Species | Optimal Thickness | Structural Benefit |

|---|---|---|

| Slate | 25mm – 40mm | Natural cleavage planes prevent crumbling during slicing. |

| Quartzite | 20mm – 35mm | High-density grains resist snapping in narrow linear profiles. |

| Marble | 25mm – 40mm | Homogeneous structure allows precision calibration for interior walls. |

Marble Selections for Refined Thin Profiles

Marble serves as a premium option for thin-cut applications where luxury aesthetics must meet strict structural weight limits. By thin-cutting marble species like Royal White, we reduce the panel weight to approximately 10-12 lbs per square foot. This weight reduction simplifies installation on interior drywall backed by cement board, removing the need for heavy-duty structural footings required for full-thickness stone.

- Precision slicing allows for a thickness range of 0.75 to 1.25 inches without compromising the stone’s integrity.

- Sophisticated mineral structures in high-grade marble ensure the surface remains consistent even at a reduced depth.

- The calibrated sawn-back finish provides a flat bonding surface that increases on-site installation speed.

Material Consistency and Manufacturing Standards

The success of thin-cut stone depends heavily on the grading of raw material and the precision of the fabrication equipment. We source blocks directly from specific quarry veins to ensure consistent mineral composition. Variations in density within a single order can lead to stone failure during the cutting process, so we maintain strict quality control at the source.

- Advanced infrared cutting equipment facilitates precise dimensional cuts, preventing the micro-cracks often found in manual slicing.

- Direct quarry sourcing ensures that stone blocks possess the stability necessary for thin-veneer applications.

- High-strength epoxy resins bond these thin-cut species when necessary, ensuring a permanent connection that resists stone fall-off over time.

Slate: The Modern Choice for Linear & Split Face Styles

Natural slate serves as the industry benchmark for high-dimension architectural surfaces, offering a proven track record of durability combined with modern split-face aesthetics that concrete replicas cannot match.

Textural Depth of Natural Split Face Slate

Natural slate panels utilize split-face quarrying to create three-dimensional surfaces that enhance architectural character. This method follows the natural cleavage planes of the stone, ensuring that the finished face retains its mineral integrity and rugged texture.

- Every panel features unique, authentic textures that distinguish genuine stone from concrete-based replicas.

- The Rough Series uses varying stone depths to produce dramatic shadows and high-dimension surfaces for accent walls.

- Split face finishes offer a rugged yet sophisticated aesthetic suitable for both mountain-style retreats and urban exteriors.

Precision Engineering for Seamless Modern Layouts

Advanced manufacturing ensures slate panels fit together precisely, supporting clean lines and linear design trends. High-precision infrared cutting equipment maintains tight dimensional tolerances, which allows contractors to achieve fast and predictable installation on large-scale commercial projects.

- Interlocking Z-shape panels eliminate visible grout lines, creating a continuous stone surface across wide spans.

- The Pencil Series incorporates thin, linear stone strips to provide a refined, fluid motion for high-end lobby feature walls.

- Factory-controlled dimensions reduce the need for extensive on-site stone masonry, lowering overall labor costs.

Weather Resistance and Color Longevity

Slate provides a durable, low-maintenance solution that retains its visual integrity despite heavy environmental exposure. Because it is a metamorphic rock formed under intense heat and pressure, it possesses inherent resistance to external stressors that degrade manufactured materials.

- Natural slate resists UV radiation, ensuring that deep charcoals and earthy greens do not fade over time.

- The material remains non-combustible, making it a safe and functional choice for modern fireplace surrounds and fire-rated exterior cladding.

- Stone surfaces require only basic cleaning with water or pH-neutral solutions to maintain their original appearance for decades.

Structural Efficiency in Multi-Surface Applications

The lightweight profile of slate panels allows for installation on various substrates without requiring extensive structural modification. This makes slate an ideal candidate for retrofitting existing buildings or for use on modern light-gauge steel framing.

- Panels weighing between 8-13 lbs per square foot typically require no additional footings or wall ledges.

- Slate panels adhere securely to cement board, brick, or concrete using high-strength epoxy resins or modified thin-set mortars.

- L-shaped corner pieces simplify transitions around columns and wall ends, creating an authentic masonry wrap that reduces site waste.

Authentic Stone Panels at Factory-Direct Prices

Quartzite: High Durability and Sparkle for Luxury Projects

Quartzite represents the pinnacle of natural stone veneer in 2026, combining a Mohs hardness of 7 with a unique crystalline structure that provides superior scratch resistance and light-reflective visual depth

Superior Hardness and Structural Integrity

Quartzite provides a robust surfacing solution that exceeds the durability of granite and marble, making it a primary choice for 2026 luxury developments. Its dense mineral structure prevents chipping and crumbling, maintaining sharp edges and clean lines over decades of use.

- A Mohs hardness rating of 7 ensures the stone resists scratches and abrasions in high-traffic commercial and residential zones.

- The dense mineral structure prevents chipping and crumbling, maintaining sharp edges and clean lines over decades of use.

- We select raw quartzite that provides the structural strength necessary for thin-cut panel manufacturing without sacrificing stability.

Natural Crystalline Sparkle and Visual Depth

The unique mineral composition of quartzite creates a signature shimmer that enhances the luxury appeal of interior feature walls and facades. This natural aesthetic serves as a high-performance alternative to marble, offering better resistance to etching while maintaining a premium visual profile.

- Embedded quartz crystals catch and reflect light, providing a dynamic visual effect that changes throughout the day.

- Designers often use these panels to achieve a high-end marble aesthetic while benefiting from the superior strength of natural stone.

- Earth-toned varieties offer a sophisticated palette that complements modern minimalist and transitional architectural styles.

Thermal Stability and UV Resistance

Quartzite maintains its color and physical properties under extreme environmental stress, making it ideal for 2026 outdoor architectural applications. Unlike manufactured concrete alternatives, natural quartzite does not degrade or off-gas when exposed to intense heat or ultraviolet light.

- The stone naturally resists UV radiation, preventing the fading or discoloration often seen in artificial alternatives.

- High thermal resistance allows for safe installation around fireplaces and in regions with significant temperature fluctuations.

- Its low porosity limits water absorption, reducing the risk of freeze-thaw damage in exterior cladding projects.

Low-Maintenance Longevity for Premium Projects

Property owners favor quartzite for its ability to retain a pristine appearance with minimal upkeep when properly installed and sealed. The material’s longevity increases the long-term asset value of commercial lobbies and high-end residential estates, ensuring the facade remains an appreciating feature of the building.

- Routine cleaning with pH-neutral solutions keeps the crystalline surface bright and free of mineral buildup.

- Applying a high-quality sealant protects the stone’s texture from environmental pollutants and organic staining.

- The material’s longevity increases the long-term asset value of commercial lobbies and high-end residential estates.

Sandstone & Limestone: Traditional Earthy Tones

Sandstone and limestone remain the industry standards for organic texture, offering 2026 architectural projects a mineral complexity and color depth that synthetic concrete composites cannot replicate.

The 2026 market shows a decisive shift toward materials that provide genuine earthy tones, ranging from warm beiges to deep ochres. Sandstone and limestone deliver these organic hues through unique mineral compositions formed over millions of years. This natural authenticity is essential for high-end projects where “faux” materials often fail to capture the subtle color shifts and crystalline structures found in genuine stone. Unlike pigmented alternatives, these stones maintain their visual integrity even under intense UV exposure.

- Every unit features distinct grain patterns and mineral inclusions, ensuring no two installations look identical.

- Natural stone maintains its color permanently, avoiding the fading issues often seen with concrete-based veneers.

- The earthy palette creates a timeless aesthetic that adds measurable resale value to residential and commercial properties.

Weather Resistance for Exterior Cladding

Sandstone remains a top choice for outdoor applications due to its natural density and ability to withstand thermal expansion. Our 2026 production focuses on high-density variants that provide a durable shield for exterior facades while maintaining a rugged, natural appearance. Because these stones are climate-tested, they resist the freeze-thaw cycles that often cause manufactured stone to delaminate or crack. The 25–40mm thickness profile ensures the stone is light enough for modern wall substrates but thick enough to provide a massive, structural feel.

- High weather resistance makes sandstone ideal for retaining walls and full building envelopes.

- Natural split faces create dramatic shadows and a robust architectural character.

- Precision sawn-back finishing allows for installation on various structural surfaces without heavy masonry footings.

Refined Interior Design with Limestone

Limestone offers a smooth, sophisticated surface that enhances interior light and creates a calm, high-end atmosphere. Designers frequently select this material for luxury lobbies and modern residential feature walls where a minimalist yet textured aesthetic is required. By utilizing a bespoke random-lay pattern, installers can create a unique wall that avoids the repetitive, “stamped” look of factory panels. The sawn-back design ensures that each individual piece bonds securely to the substrate with 30% less labor than traditional unrefined stone.

- Flat series limestone provides clean lines that fit perfectly with contemporary and minimalist decor.

- Soft color transitions provide a neutral yet textured backdrop for high-traffic reception areas.

- Individually sawn-back pieces ensure a flat bonding surface for maximum adhesion.

Specialized Finishes for Modern Projects

Advanced manufacturing techniques allow for diverse surface treatments on sandstone and limestone, such as honing and sandblasting. These finishes adapt traditional stones to meet specific tactile and visual requirements for specialized architectural designs. Whether the goal is a sleek, matte finish for a modern corridor or a sandblasted texture for slip resistance, the physical properties of natural stone allow for a level of customization that engineered materials cannot match.

- Infrared cutting equipment achieves exact dimensions, ensuring stones fit together with high precision.

- High-strength bonding agents create a permanent connection between the stone and the wall.

- A three-stage inspection process during cutting and packaging maintains strict durability standards.

Comparing Water Absorption Across Stone Types

Quantifying water absorption rates serves as the primary technical baseline for predicting the long-term structural integrity and aesthetic stability of natural stone cladding.

Absorption Profiles for Dense and Porous Stones

Stone varieties exhibit a wide range of water absorption capacities that dictate their suitability for specific architectural environments. Granite and marble feature extremely low absorption rates, typically staying below 0.1% due to their dense crystalline structure. These materials act as nearly impermeable barriers, making them ideal for high-exposure commercial facades.

Sedimentary stones like limestone and sandstone possess higher porosity, with absorption levels often exceeding 10% in untreated states. For most vertical applications, slate and quartzite offer a balanced middle ground. These species provide natural water resistance that prevents saturation while maintaining the breathability required for exterior wall systems.

| Stone Species | Absorption Rate (ASTM C97) | Best Use Case |

|---|---|---|

| High-Density Quartzite | < 0.5% | Pool Surrounds & Coastal Areas |

| Metamorphic Slate | 0.5% – 2.0% | Exterior Cladding & Roofing |

| Architectural Limestone | 3.0% – 12.0% | Protected Arid Environments |

Impact of Porosity on Durability and Maintenance

The rate at which a stone absorbs liquid directly influences its resistance to staining and environmental weathering. Higher absorption rates increase the risk of freeze-thaw damage. When trapped water expands during temperature drops, it creates internal pressure that can lead to spalling or surface delamination in porous species.

- Porous stones require more frequent application of high-quality sealants to prevent deep-set organic staining or efflorescence.

- Natural stone ledger panels provide long-term value because they do not fade from UV exposure, staying visually consistent regardless of moisture levels.

- Low-porosity quartzite maintains a “crystalline sparkle” even in high-humidity zones where other stones might appear dull.

Industry Standard Testing for 2026 Project Specifications

Current engineering standards utilize rigorous testing to verify stone performance for commercial and residential safety. ASTM C97 remains the primary benchmark for measuring the density and water absorption of dimension stone. Specifiers for 2026 projects prioritize low-absorption materials for high-moisture areas like pool surrounds and commercial entryways to mitigate liability and maintenance costs.

Standardized data allows contractors to determine if specific structural footings are necessary. Our thin-cut panels, maintained at 25–40mm thickness, avoid the heavy footing requirements of full-bed stone while still offering the weather resistance of traditional masonry.

Substrate and Sealing Requirements in Wet Areas

While stone is naturally water-resistant, the ledger panel system requires specific installation steps in moisture-prone zones. Exterior installations must include a moisture barrier and proper flashing. The stone itself provides the aesthetic and primary shield, but the system must handle incidental water behind the veneer.

We recommend applying a premium natural stone sealer after installation to facilitate easy cleaning and prevent moisture-related discoloration. Note that siliceous stones like slate and quartzite require different sealant chemistries than calcareous stones like marble for optimal bonding. Using the correct chemical match ensures the sealant penetrates the surface rather than just sitting on top, providing a lifetime of protection.

Conclusion

Selecting the right stone species balances visual appeal with technical requirements like moisture resistance and structural durability. Using precision-cut, sawn-back veneers provides the authentic look of full-depth masonry while reducing load requirements and on-site labor. Sourcing these materials from a single quarry vein ensures color consistency across large-scale commercial developments.

View our full collection of natural stone veneers or contact our team for technical specifications and wholesale pricing. We provide digital catalogs and sample kits for specifiers managing multi-unit housing or commercial projects.

Frequently Asked Questions

What is the most durable natural stone veneer?

Granite is widely considered the most durable natural stone veneer available. Due to its high density and mineral composition, it offers superior resistance to scratching, heat, and extreme weathering. Quartzite is a close second, providing similar hardness with a different aesthetic profile.

Is slate good for exterior walls?

Yes, slate is an excellent material for exterior walls. It is naturally non-porous and has a very low water absorption rate, which makes it highly resistant to frost damage and staining. Its inherent durability and fire resistance have made it a staple in premium architectural facades for decades.

Which stone is best for a modern look?

For a modern aesthetic, basalt and honed limestone are the preferred choices. Stones with monochromatic palettes—such as charcoal, deep black, or soft bone-white—and clean-sawn edges provide the minimalist, sleek appearance required for contemporary designs.

Does limestone stain easily?

Limestone is a porous, calcium-based stone, which makes it more susceptible to staining from oils and acidic liquids compared to igneous rocks like granite. However, when treated with a high-quality, breathable impregnating sealer, limestone becomes highly resilient and suitable for high-traffic or outdoor areas.

What is the difference between slate and quartzite?

The primary difference lies in their formation and hardness. Slate is a fine-grained, foliated metamorphic rock that splits easily into thin sheets, making it ideal for layered textures. Quartzite is a much harder, non-foliated metamorphic rock formed from sandstone; it offers a crystalline look and is significantly more resistant to abrasion and scratching.

How to choose stone color for a house?

To select the right color, evaluate your home’s fixed elements like the roof and window trims. For a cohesive look, choose a stone that shares a common undertone with these features. Use warm tans and browns for traditional architecture, and cool grays or dark blacks for modern structures. Always observe stone samples in the specific natural light where they will be installed.